In any fluid system, a y-strainer and a ball valve are best friends. While the y strainer acts as the “shield” by filtering out debris, the ball valve serves as the “gatekeeper” for isolation and maintenance.

Installing a y-strainer valve without proper isolation valves is a common mistake that leads to messy maintenance and system downtime. In this guide, we explore why this combination is the industry standard for HVAC, water treatment, and industrial processing.

Table of Contents

ToggleI. The Anatomy of a Filtration Station

To protect a pump or a sensitive control valve, engineers typically design a “station” consisting of three primary components:

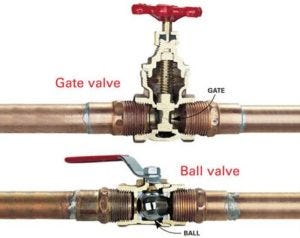

Upstream Ball Valve: Used to shut off the fluid source.

Y-Strainer (Wye Strainer): The core filter y strainer that captures scale, rust, and debris.

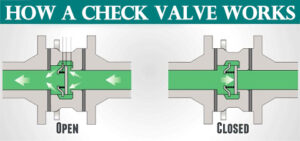

Downstream Ball Valve: Prevents backflow from the rest of the system when the strainer cap is removed.

Pro Tip: For high-efficiency systems, a small drain ball valve is often installed on the Y-strainer’s blow-off port. This allows operators to flush out the strainer mesh without stopping the entire flow.

II. Why You Must Use Ball Valves with Y-Strainers

Using ball valves in conjunction with your y strainer valve offers three critical advantages:

1. Maintenance Without System Shutdown

Without isolation valves, cleaning a y-strainer screen would require draining the entire pipeline. With a ball valve on either side, you can isolate the “station,” clean the mesh, and restart in minutes.

2. Protecting Valve Seats

Debris is the #1 killer of ball valve seats. By placing the y-type strainer upstream, you ensure that the closing mechanism of the downstream valves remains free from scratches and leaks.

3. Pressure Monitoring

By installing a ball valve with a pressure gauge port near the strainer, you can monitor the pressure drop (ΔP) across the y strainer filter mesh to know exactly when it needs cleaning.

III. Selecting the Right Mesh for Your Valves

The y strainer mesh size must be matched to the equipment it protects.

For Ball Valves: A standard 20 to 40 mesh is usually sufficient.

For Solenoid or Control Valves: A finer strainer filter mesh (60-100 mesh) is required to prevent small particles from jamming the delicate internal pilots.

| Application | Recommended Mesh Size | Material |

| HVAC Chilled Water | 20 – 40 Mesh | Stainless Steel 304 |

| Steam Lines | 40 – 60 Mesh | Stainless Steel 316 |

| Fine Chemical/Oil | 100+ Mesh | Monel or 316L |

IV. Installation Best Practices: HVAC & Water Systems

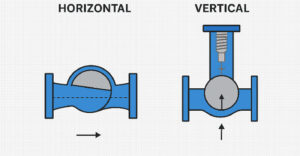

For hvac strainer applications or chilled water strainers, orientation is key:

Horizontal Lines: The “Y” part should point downwards so that gravity helps collect debris in the pocket.

Vertical Lines: Only install y strainers in vertical lines with downward flow. This ensures debris is trapped and doesn’t fall back into the pipe when the flow stops.

V. Buying Guide: Combined Valve & Strainer Kits

When searching for a y strainer valve for sale, consider purchasing a pre-assembled or matched set. This ensures:

Compatible Pressure Ratings: Both the ball valve and the strainer y type should be rated for the same pressure (e.g., PN25 or Class 150).

Material Harmony: Prevents galvanic corrosion between different metals.

Conclusion

The y-strainer valve is only as good as the system it lives in. By integrating high-quality ball valves into your filtration setup, you ensure a cleaner, safer, and more maintainable operation. Whether you are managing an hvac strainer in a commercial building or a high-pressure line in a factory, the “Valve + Strainer” combo is your best insurance policy.