In any fluid control system, preventing reverse flow is a top priority for protecting pumps, preventing contamination, and ensuring operational safety. However, when reviewing specifications or ordering parts, many professionals use the terms Backflow Preventer Valve and Check Valve interchangeably.

While their ultimate goal is the same—stopping fluid from moving in the wrong direction—their mechanical designs, safety ratings, and legal requirements are vastly different. This guide breaks down the critical differences to help you make the right choice for your project.

Table of Contents

ToggleI. What is a Check Valve?

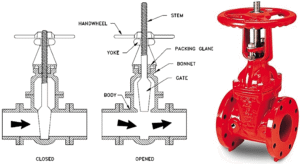

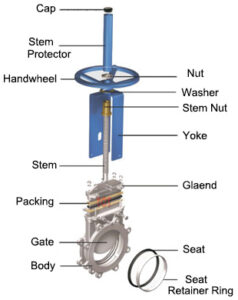

A Check Valve (also known as a non-return valve or valve check) is a relatively simple automatic device.

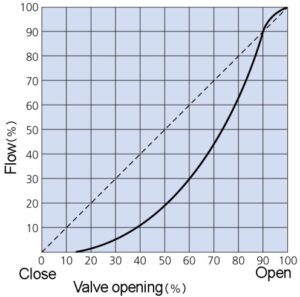

Working Principle: It relies on the flow of the medium to open. When the flow stops or attempts to reverse, the internal mechanism (disc, ball, or flap) closes under the force of gravity or a spring.

Common Types: The most popular designs include the Swing Check Valve, Lift Check Valve, and Dual-Plate Wafer Valve.

Primary Purpose: It is designed to protect equipment. It prevents “water hammer,” protects pumps from being spun backward by returning fluid, and maintains system pressure.

II. What is a Backflow Preventer?

A Backflow Preventer is a far more complex assembly, typically consisting of two independent check valves and an intermediate relief chamber.

Working Principle: It does more than just block reverse flow. If it detects a pressure anomaly, it uses a specialized relief valve to vent the potentially contaminated water out of the system entirely.

Safety Rating: Its primary purpose is to protect public health. It ensures that “non-potable” water (such as industrial waste, chemicals, or fire-safe water) cannot back-siphon into the clean drinking water supply.

Legal Requirements: In many municipal and industrial codes, Backflow Preventer Valve installation is mandatory for cross-connection control and must be certified by local authorities.

III. Core Comparison: Backflow Preventer vs. Check Valve

| Feature | Check Valve | Backflow Preventer |

| Complexity | Single internal component | Assembly of multiple valves |

| Main Function | Protects pumps and equipment | Protects public drinking water |

| Safety Level | Moderate (Small risk of seal failure) | Extremely High (Fail-safe/Auto-venting) |

| Testing | Usually maintenance-free | Mandatory annual testing by law |

| Search Terms | swing check valve, valve check | backflow preventer, water backflow valve |

IV. How to Choose Based on Application

1. Industrial Process & Loop Control

If your goal is simply to keep a pump from losing its prime or to prevent fluid from returning to a tank during a shutdown, a standard Check Valve is the correct tool.

Recommended: Select a Swing Check Valve for high-flow, low-pressure drop systems.

2. Municipal & Potable Water Connections

If your facility’s piping connects to the city water supply, you are likely legally required to install a certified Backflow Preventer Valve to prevent industrial water from contaminating the city grid.

Search Tip: Users looking for

backflow preventer valveorwater back flow valveare usually dealing with these regulatory environments.

3. Hot Water & Boiler Systems

In heating systems, thermal expansion creates pressure fluctuations. Here, a Check Flow Valve is often paired with a Hot Water Pressure Relief Valve to ensure the system neither over-pressurizes nor allows backflow.

V. Maintenance Tip: Why Do These Valves Fail?

The #1 cause of failure for both a Backflow Preventer and a Check Valve is debris (rust, scale, or weld slag) getting trapped in the seal.

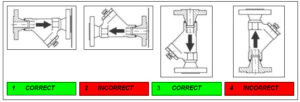

The Solution: Installing a Y-Strainer upstream of these valves can significantly extend their lifespan and prevent costly leakage or inspection failures.

Conclusion

In summary, a Check Valve is an “Engineering Tool” used to protect your system’s hardware, while a Backflow Preventer is a “Regulatory Barrier” used to protect health and safety. Understanding this distinction can save you money on procurement and ensure your system stays compliant with local safety codes.