The check valve (or non-return valve) is one of the most common components in any piping system. While its primary function—preventing backflow—is simple, choosing the wrong check valve type can lead to “water hammer,” severe pump damage, and costly system downtime.

With numerous designs available on the market, how do you decide which one fits your specific application? In this guide, we dive deep into the pros and cons of the three industry standards: Swing Check Valves, Lift Check Valves, and Spring-Loaded Check Valves.

Table of Contents

ToggleI. Swing Check Valve: The Industry Standard

The Swing Check Valve is the most widely searched (2,400) and utilized design in general industrial applications.

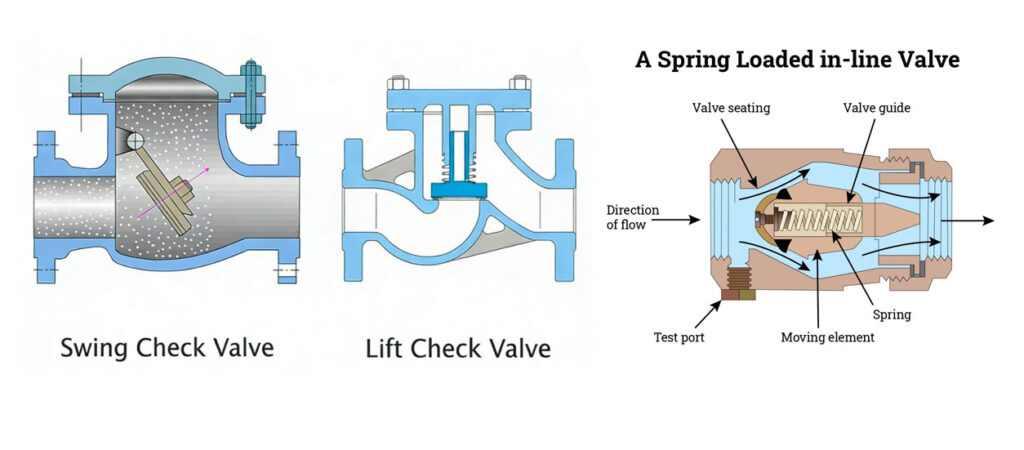

Mechanism: It features a disc that swings on a hinge or trunnion off the seat to allow forward flow and swings back onto the seat when the flow stops.

Pros: * Lowest Pressure Drop: The full-port design offers minimal resistance to flow.

Cost-Effective: Extremely economical, especially for large-diameter pipelines.

Cons: Not suitable for systems with frequent flow reversals; prone to “slamming” in high-pressure systems.

Best Usage: Wastewater, irrigation, and low-velocity cooling water loops.

II. Lift Check Valve: The High-Pressure Specialist

The Lift Check Valve design is structurally similar to a globe valve.

Mechanism: The disc, or piston, travels vertically up and down. The upstream pressure “lifts” the disc off the seat to allow flow.

Pros: * Superior Sealing: Offers a much tighter seal than the swing variety.

Durability: Highly resistant to wear in high-pressure environments.

Cons: Significant pressure drop due to the diverted flow path; limited primarily to horizontal installations.

Best Usage: High-pressure steam, compressed air, and gas services.

III. Spring-Loaded Check Valve: The Water Hammer Solution

Often called “Silent Check Valves,” these use a spring to assist in closing the valve before flow reversal can occur.

Mechanism: A spring forces the disc to close the moment fluid velocity decreases, even before the flow actually reverses.

Pros: * Eliminates Water Hammer: The rapid closure prevents the loud “thud” and shockwaves associated with backflow.

Versatile Installation: Can be installed in any orientation (horizontal, vertical up, or vertical down).

Cons: Requires a specific cracking pressure (the minimum pressure to compress the spring) to open.

Best Usage: High-head pump systems, chemical processing, and vertical piping.

IV. Quick Selection Matrix

| Feature | Swing Check Valve | Lift Check Valve | Spring-Loaded |

| Pressure Drop | Lowest | High | Moderate |

| Sealing Quality | Moderate | Excellent | Excellent |

| Installation | Horizontal/Vertical Up | Horizontal Only | Any Direction |

| Water Hammer Risk | High | Moderate | Lowest (Silent) |

| Search Terms | swing check valve | lift check valve | spring check valve |

V. 3 Critical Factors to Consider Before Buying

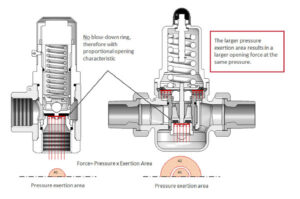

1. Cracking Pressure

For systems with low-power pumps, you must ensure the pump’s output pressure is significantly higher than the valve’s cracking pressure. If it isn’t, the valve may only partially open, leading to pump overheating.

2. Media Cleanliness

If your fluid contains solids or grit, a Swing Check Valve is prone to getting jammed. In these cases, we strongly recommend installing a Y-Strainer upstream to protect the valve seat.

3. Vertical vs. Horizontal

Remember that a standard Swing Check Valve relies on gravity to help it close. If your pipe is running vertically downward, a swing check will stay open, failing to stop backflow. In vertical down-flow scenarios, a Spring-Loaded Check Valve is mandatory.

Conclusion

There is no “perfect” valve—only the right valve for your specific operating conditions. Swing Check Valves are best for energy-efficient, large-scale water flow; Lift Check Valves handle the rigors of high-pressure gas; and Spring-Loaded designs are the ultimate problem-solvers for noise and vertical installations.