Table of Contents

ToggleWhat is a Balancing Valve? (The Straight Answer)

At its core, what is a balancing valve? Most people will tell you it’s a valve that regulates flow. But a more accurate, professional definition is this: A balancing valve is a “pre-settable resistor” for your piping system.

Think of your building’s piping like an electrical circuit. Without resistors, the current (water) would all rush through the shortest path, leaving the rest of the system “dark.” A balancing valve creates the exact amount of back-pressure needed to force water into every branch of the system, ensuring that the furthest radiator on the top floor performs just as well as the one next to the boiler.

Real-World Logic: What Does a Balancing Valve Do?

If you are troubleshooting a noisy or uneven system, you are likely asking: What does a balancing valve do that a standard ball valve can’t?

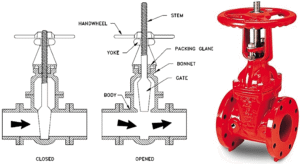

While a ball valve is for isolation (On/Off), a balancing valve performs three “active” roles that stabilize your infrastructure:

Ensures Design Flow (GPM): It limits the flow to a specific branch so it doesn’t “steal” water from others.

Facilitates Measurement: It provides a diagnostic point. By using the balancing valve symbol ports, you can measure exactly how many gallons per minute are moving through a pipe.

Protects the Delta T (ΔT): In chilled water systems, it prevents water from moving too fast. If water moves too quickly through a coil, it doesn’t have time to exchange heat, leading to “Low Delta T Syndrome” which kills chiller efficiency.

Why “Manual” Isn’t Always Enough (Static vs. Dynamic)

Many engineers still rely on the old-school balancing valve symbol—the manual orifice valve (Static). It works, but only if the system never changes.

The Reality Check:

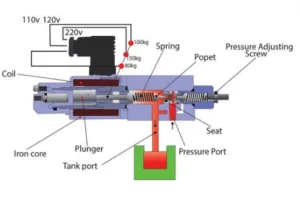

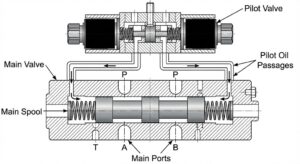

Modern buildings are dynamic. VAV boxes open and close; thermostats kick in and out. If you use a manual water balancing valve, the moment one zone closes, the pressure shifts and throws every other zone out of balance.

The Insight: If your project involves variable speed pumps, stop looking at static valves. You need Pressure Independent Control Valves (PICVs). They act as a balancing valve and a control valve in one, “absorbing” pressure fluctuations so the flow remains constant regardless of what’s happening elsewhere in the loop.

The “Hot Water Return” Nightmare: A Case Study

We recently consulted on a hotel project where guests in the North Wing had to run the shower for 5 minutes to get hot water. The hot water return balancing valve was installed, but it was set based on a “rule of thumb” rather than actual pipe length calculations.

The Fix: We didn’t just open the valve; we used a temperature balancing valve (Thermal Balancing). Instead of balancing by flow (GPM), it balances by temperature.

The Result: By ensuring the return water stayed at 60°C across all branches, the “lag time” for hot water dropped from 300 seconds to 8 seconds.

Reading the P&ID: The Symbol vs. The Hardware

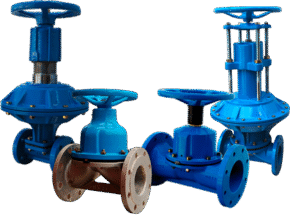

When you see the balancing valve symbol on a blueprint, it often looks like a bow tie with a signal line. But in the field, the most important part of that symbol is the PT Ports (Pressure Test Ports).

Field Tip: Never buy a balancing valve without high-quality test ports. If you can’t measure the differential pressure (ΔP), you aren’t balancing—you’re guessing.

Maintenance: The “Set and Forget” Fallacy

The biggest mistake we see in plumbing balancing valve maintenance is the “Set and Forget” mentality. Over 5-10 years, scale buildup changes the internal diameter of your pipes.

Actionable Advice: If you are managing an HVAC balancing valve in a chilled water system, re-verify your flow rates every 3 years. A system that was perfectly balanced in 2020 is likely over-circulating by 15% today due to mechanical wear and debris.

Technical Selection Cheat Sheet

| The Problem | The Symptom | The Right Valve |

| Short Circuiting | Near zones too hot; far zones cold. | Manual Circuit Setter (Static) |

| Variable Load | Noise in pipes; fluctuating temps. | PICV (Dynamic) |

| Legionella Risk | Lukewarm water in return lines. | Thermostatic Balancing Valve |

| High Pump Cost | High ΔT (Delta T) at the chiller. | Differential Pressure Controller |

Conclusion

A balancing valve is the only component in your mechanical room that pays for itself. By optimizing the flow, you reduce pump wear, eliminate tenant complaints, and slash carbon emissions.