In a chilled water loop, water is the vehicle for heat transfer. If the water moves too fast, it doesn’t stay in the cooling coil long enough to absorb heat (the dreaded Low Delta T Syndrome). If it moves too slow, the zone starves.

Choosing the right chilled water balancing valve is about more than just pipe size; it’s about controlling the hydraulic dynamics of a shifting load. For high-performance buildings, the debate always comes down to: Static vs. Dynamic.

Table of Contents

Toggle1. Static Balancing: The Reliable “Circuit Setter”

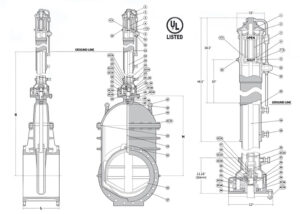

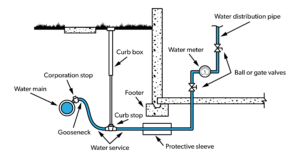

When you see a standard balancing valve symbol on an older blueprint, it usually refers to a static valve, often called a manual circuit setter.

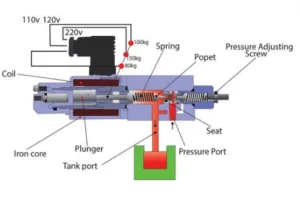

How it works: You manually adjust a plug or orifice to create a permanent resistance.

The Field Reality: Static valves are “blind.” They are set for full-load conditions, which only happen about 5% of the year. The rest of the time, as control valves across the building modulate, the static valve becomes an obstacle that forces your pumps to work harder than necessary.

Best for: Constant flow systems (fixed-speed pumps) where the load never changes.

2. Dynamic Balancing: The PICV Revolution

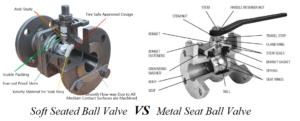

In modern HVAC balancing valve design, the Pressure Independent Control Valve (PICV) has become the industry benchmark for chilled water.

What it does: It combines a balancing valve, a control valve, and a pressure regulator into one body.

The “Magic” of PICV: No matter how much the system pressure fluctuates (due to other zones closing), the PICV maintains a constant flow to its terminal.

The ROI: By preventing “over-pumping” during part-load hours, a chilled water balancing valve of the dynamic variety can reduce pump energy consumption by up to 25-30%.

3. The “Low Delta T” Killer

For facility managers, the biggest nightmare is a chiller plant that is running at full capacity but not cooling the building. This is often caused by a lack of proper flow balancing valves.

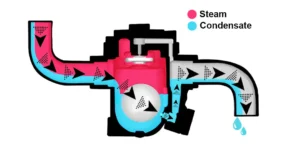

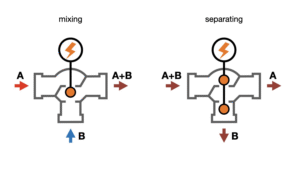

The Scenario: Water “overflows” through some coils so fast that the return water is still cold. The chiller sees this cold return water and thinks the building is satisfied, so it stages down—even though half the building is still hot.

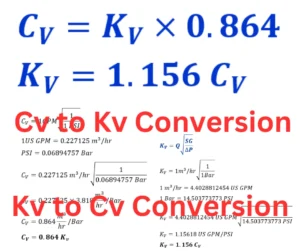

The Solution: By using a balancing valve in hvac loops to strictly limit flow to the design GPM, you force the water to spend more time in the coil, ensuring a high $ΔT$ and keeping your chillers running at peak efficiency.

4. Understanding Symbols and Diagnostics

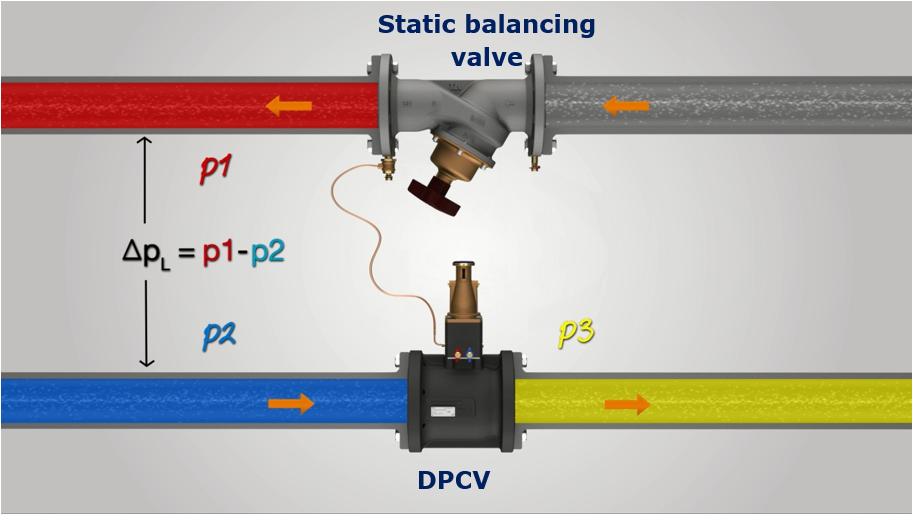

When reviewing your P&ID, the balance valve symbol for a dynamic valve often includes an extra “P” or a pressure-sensing line.

Expert Tip: In chilled water balancing valves, always check for high-accuracy PT ports. In cooling systems, even a small error in flow measurement can lead to humidity issues and mold growth in the air ducts. Accurate diagnostics are your first line of defense.

5. Selection Guide: Static or Dynamic?

| System Type | Recommended Valve | Key Benefit |

| Fixed Speed Pumps | Manual Static Valve | Low cost, simple setup. |

| Variable Speed (VFD) | PICV (Dynamic) | Massive energy savings. |

| Industrial Process Cooling | Automatic Flow Limiter | Prevents equipment starvation. |

| Remote Branch Lines | Differential Pressure Valve | Eliminates pipe noise/whistling. |

Conclusion: Data-Driven Cooling

A chilled water balancing valve is no longer a “set-and-forget” piece of brass. It is a critical data point in your building’s energy profile. Whether you choose the rugged simplicity of a static circuit setter or the high-tech precision of a PICV, the goal remains the same: Precision flow for maximum heat transfer.