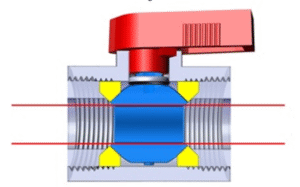

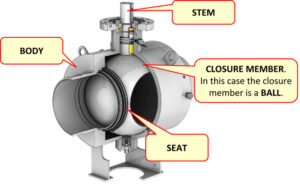

The ball valve is the workhorse of the industrial world because of one promise: a bubble-tight shutoff. But when that promise fails, the consequences range from a minor nuisance to a catastrophic plant shutdown.

If you are dealing with a leaking ball valve or a handle that won’t budge, the problem usually isn’t the valve itself—it’s a mismatch between the valve’s specs and your system’s reality. In this guide, we’ll look at the “Big Five” failure points we see in the field and how to prevent them.

Table of Contents

Toggle1. The “Throttling” Trap: Why Ball Valves Aren’t Control Valves

The most common cause of ball valve seat failure is using it to regulate flow (throttling).

The Physics: A standard ball valve is designed to be either 100% open or 100% closed. When you leave it “half-open,” the high-velocity fluid creates a “wire-drawing” effect on the exposed edge of the soft seat (PTFE).

The Result: Once the seat is scarred, the valve will never achieve a tight seal again.

The Fix: If you need to regulate flow, use a Globe Valve or a V-Port Ball Valve. If your valve is already leaking, check for “half-moon” erosion patterns on the seat.

2. Seat Material Mismatch: PTFE is Not a Magic Bullet

Many buyers search for ball valves assuming standard Teflon (PTFE) handles everything. This is a costly mistake.

Insight from the Field: We recently saw a batch of valves fail in a steam system because the operator used virgin PTFE instead of Reinforced PTFE (RPTFE) or Carbon-Filled PTFE. The heat caused the seats to “cold flow” (deform), leading to an immediate internal leak.

Pro Tip: For temperatures exceeding $200°C$ or high-cycle applications, stop using soft seats. This is where Metal Seated Ball Valves become the only viable solution to prevent constant replacements.

3. The “Stuck” Valve: Dealing with Stem Seizure

A stuck ball valve is usually the result of “Media Buildup” or “Galling.”

The Cause: In systems with heavy particulates or scaling (like hard water), debris settles in the cavity between the ball and the body. If the valve isn’t cycled regularly, this debris hardens into “cement.”

The Solution: Implement a “Exercise Program” for critical valves. Cycling the valve 90 degrees once a month can break up mineral deposits before they seize the stem. For automated systems, ensure your pneumatic ball valve actuator has enough torque to overcome the “breakaway” friction of a dormant valve.

4. Cavitation: The Silent Destroyer

If you hear a sound like “marbles rattling” inside your pipe, your ball valve is experiencing cavitation.

What happens: High-pressure drops across the valve cause vapor bubbles to form and then collapse violently against the ball. This can actually “pit” the stainless steel surface of the ball, making it look like it was hit by a shotgun.

The Fix: Review your system’s pressure drop. You may need to install valves in series or choose a valve with a “multi-stage” trim to dissipate the energy.

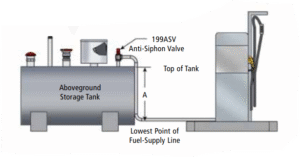

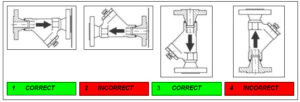

5. Maintenance: Why You Should Always Use a Y-Strainer

If you are buying ball valves valves (double-checking your inventory), you should also be buying Y-Strainers.

The #1 enemy of a ball valve seat is “Weld Slag” or pipe scale left over from construction. A single sharp metal shaving can ruin a brand-new $1,000 valve in one turn.

Actionable Advice: Always install a strainer upstream of any critical ball valve. It is 10 times cheaper to clean a strainer than to replace a high-pressure ball valve.

Ball Valve Troubleshooting Matrix

| Symptom | Likely Cause | Recommended Action |

| Internal Leak (Closed) | Seat erosion or “Wire-drawing.” | Check for throttling usage; replace seat. |

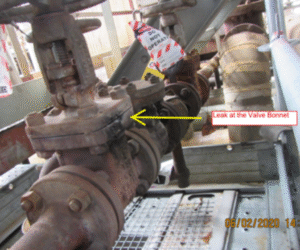

| External Leak (Stem) | Packing wear or over-pressurization. | Tighten packing nut or replace O-rings. |

| Handle Won’t Turn | Scale buildup or seat swelling. | Flush system; check chemical compatibility. |

| Pitted Ball Surface | Cavitation or Chemical Corrosion. | Upgrade to Metal Seats or Alloy 20/Monel. |

Conclusion: Stop Buying Valves, Start Buying Reliability

A ball valve is only as good as its selection process. By understanding the limits of seat materials and the dangers of throttling, you can extend your system’s MTBF (Mean Time Between Failures) from months to years.