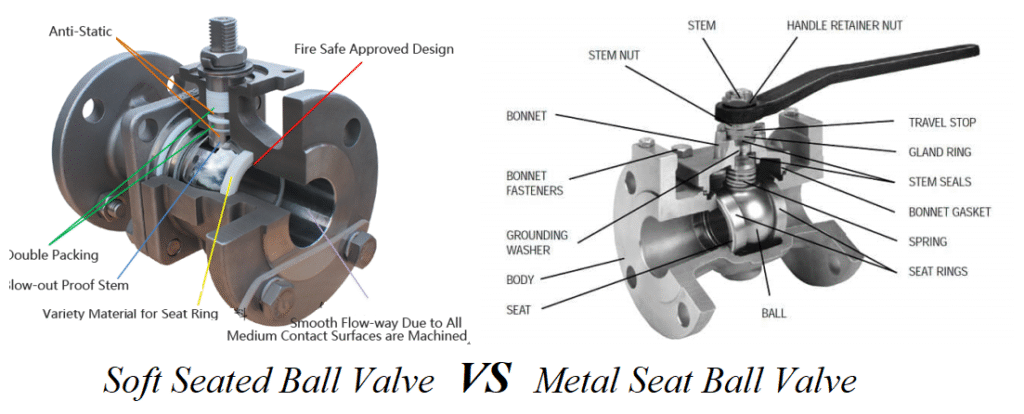

The soul of a ball valve is its seat. It is the interface that determines whether your valve will hold a “bubble-tight” seal or fail within weeks. While most off-the-shelf valves come with a standard soft seat (usually PTFE), many industrial environments—from steam lines to abrasive slurries—will shred these materials in a heartbeat.

Choosing between a soft seated ball valve and a metal seated ball valve isn’t just about price; it’s about the physics of your system. Here is the technical breakdown to help you decide.

Table of Contents

Toggle1. Soft Seated Ball Valves: The Precision Standard

Soft seats are made of thermoplastic materials like PTFE, RPTFE (Reinforced), or PEEK.

The Advantage: They offer a Class VI “Bubble-Tight” shutoff. Because the material is slightly compressible, it deforms perfectly against the ball to create a zero-leakage seal.

The Limitation: Temperature and abrasion. Standard PTFE begins to “cold flow” (lose its shape) at 180°C (356°F). Furthermore, if the fluid contains sand or pipe scale, it will embed into the soft seat, acting like sandpaper against the ball.

Best Use Cases: Clean water, chemicals at moderate temperatures, and gas applications where zero leakage is mandatory.

The Achilles’ heel of a soft seat isn’t just heat—it’s debris entrapment. In a soft seat, a single metal shard or a piece of pipe scale can become permanently embedded in the PTFE. Every time the valve turns, that shard acts like a lathe, gouging the ball until the valve leaks.

2. Metal Seated Ball Valves: The “Hardened” Solution

In a metal seated ball valve, the ball and seat are both made from metal (typically 316 SS) and are often coated with specialized hard-facings like Tungsten Carbide or Chrome Carbide.

The Advantage: Extreme durability. These valves can handle temperatures exceeding 500°C (932°F) and are virtually immune to the abrasive wear of slurries or catalysts.

The Limitation: Cost and Leakage Class. Metal seats are significantly more expensive to manufacture because the ball and seat must be “match-lapped” (ground together as a pair). Even then, they typically achieve Class IV or V shutoff, which allows for a microscopic, measured amount of seepage.

Best Use Cases: High-pressure steam, oil refinery “coker” units, mining slurries, and any application involving high temperatures or solids.

- Chrome Plating: Used for general wear and tear.

- Tungsten Carbide (WC): The industrial standard, used for highly abrasive slurries.

- Stellite: A classic solution for high-temperature resistance and impact resistance.

The Physics of Thermal Expansion

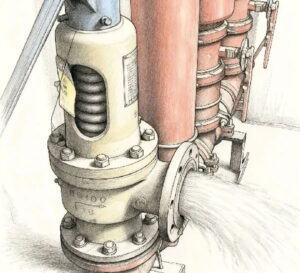

When engineering a metal seated ball valve for high-heat applications (above 300°C), simple metal-to-metal contact isn’t enough. Our designs utilize spring-loaded seat assemblies. This ensures that as the ball and seats expand at different rates due to thermal cycles, the valve remains operational and doesn’t “seize” or lock up under extreme temperatures.

3. Comparison Table: At-A-Glance Selection

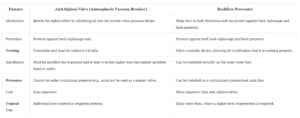

| Feature | Soft Seat (PTFE/PEEK) | Metal Seat (Hardened Steel) |

| Sealing Level | Class VI (Zero Leak) | Class IV or V (Minimal Leak) |

| Max Temperature | Up to 250°C (for PEEK) | Up to 600°C+ |

| Abrasion Resistance | Low (Susceptible to scarring) | Excellent |

| Torque Requirement | Lower | Higher |

| Cost | Economic | Premium / High Investment |

4. The Middle Ground: Reinforced and Carbon-Filled Seats

If your system is “too hot” for virgin PTFE but you can’t justify the cost of a metal seat ball valve, consider these upgrades:

RPTFE (Glass Reinforced): Adds structural strength to prevent the seat from deforming under pressure.

Carbon-Filled PTFE: Offers better thermal conductivity and lower friction, extending the life of automated ball valves.

PEEK: The “Super Plastic.” It can handle higher pressures and temperatures (250°C) while still maintaining a bubble-tight seal.

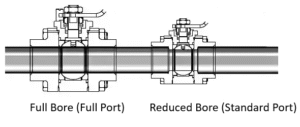

5. Why Seat Choice Affects Your Actuator

When you switch from soft to metal seats, your breakaway torque (the force needed to start the valve’s turn) increases significantly.

Technical Note: If you are using a pneumatic ball valve actuator, you must re-calculate your torque requirements when upgrading to metal seats. A motor or piston that worked fine on a Teflon valve will likely stall on a metal-seated one.

Expect your breakaway torque to increase by 40% to 100% when switching from PTFE to Metal Seats. This often requires stepping up to the next size of actuator to ensure reliable operation.

Conclusion: Engineering for Longevity

Don’t let a low upfront price lead to a high maintenance cost. If your ball valve is failing every 6 months, it’s a sign that your seat material is being outmatched by your environment. Upgrading to a metal seat or a high-performance polymer like PEEK can extend your service life by years.