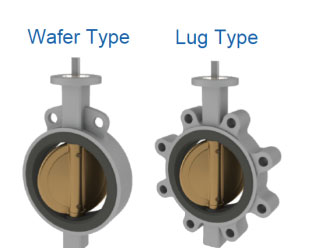

The butterfly valve is the “workhorse” of modern piping due to its slim profile and quarter-turn efficiency. But when you are looking at a spec sheet, the choice between Wafer and Lug body styles is often treated as a mere pricing decision. This is a dangerous mistake.

Choosing the wrong body style can lead to catastrophic system drainage during maintenance or flange leaks during thermal cycles. This guide goes beyond the basics to explain the “Physics of Selection” so you can choose the right valve for safety, not just budget.

Table of Contents

Toggle1. Wafer Butterfly Valves: The Budget-Friendly Standard

The wafer butterfly valve is designed to be “sandwiched” between two pipe flanges. It has no threaded holes; it is held in place by long bolts that span the entire width of the valve and both flanges.

The Pros:

Lowest Upfront Cost: Minimal material used in the body.

Lightweight: Ideal for plastic piping systems (PVC/CPVC) where heavy valves can stress the pipe.

Compact: Fits in the tightest footprints.

The “Fatal” Limitation:

No Dead-End Service. You cannot remove the downstream piping while the system is under pressure. If you remove the bolts on one side, the valve has nothing to hold it in place. The seal will fail immediately, and your system will drain.

2. Lugged Butterfly Valves: The Safety Specialist

A lug style butterfly valve features threaded metal inserts (lugs) around the body. Instead of long bolts, it uses shorter, independent bolts for each side of the flange.

The Advantage: Dead-End Service

This is the single biggest reason to upgrade to a Lug valve. You can close the valve and disconnect the piping on the downstream side for cleaning or pump maintenance. The valve remains securely bolted to the upstream flange, maintaining the system seal.

The Thermal Factor (Expert Insight):

In systems with thermal cycling (hot/cold shifts), Wafer valves are prone to leaking. Long bolts expand and contract more than the short bolts used in Lug valves. This “bolt stretch” can compromise the flange seal. For steam or high-temp water, the Lug style is significantly more reliable.

3. Comparison Matrix: Performance & Risk

| Feature | Wafer Style | Lug Style |

| End-of-Line Service | Strictly Forbidden | Safe / Recommended |

| Bolting Method | Long through-bolts | Short independent bolts |

| Thermal Expansion | High risk of flange leaks | Minimal / Stable |

| Maintenance | Requires system shutdown | Allows partial isolation |

| Weight | ~20% Lighter | Heavier (More metal) |

| Total Cost | Low Unit Price | Lower Labor Cost (Maintenance) |

4. The 3 Most Critical Selection Mistakes

Mistake #1: Using a Wafer Valve for Pump Suction

If your pump needs a strainer cleaned or a seal replaced, a Wafer valve will force you to drain the entire line. A Lug valve at the pump inlet allows for quick isolation and maintenance without dumping thousands of gallons of fluid.

Mistake #2: Ignoring the “Dead-End” Pressure Rating

Not all Lug valves are created equal. Some are rated for 200 PSI in-line but only 50 PSI in dead-end service. Always check the “Dead-End Pressure Rating” if you plan to remove downstream piping.

Mistake #3: Overtightening Plastic Flanges

In PVC or HDPE systems, Wafer valves are actually safer. If you use a Lug valve and tighten the bolts into the metal threads too hard, you can easily crack the plastic flange. In plastic systems, “sandwiching” with a Wafer valve distributes the pressure more evenly.

5. Frequently Asked Questions (FAQ)

Q: Can a Wafer valve be converted to a Lug valve?

A: No. The body castings are fundamentally different. You must specify the style during the procurement phase.

Q: Is there a price difference?

A: Yes, Lug valves are generally 15%–25% more expensive due to the extra metal and the labor of machining the threaded holes.

Q: Which is better for high-vibration systems?

A: The Lug style is superior. The independent bolting ensures that vibration on one side of the pipe doesn’t loosen the bolts on the other side.

Conclusion: Balancing Safety and Savings

If you are working on a non-critical HVAC water loop where the system is rarely serviced, a Wafer butterfly valve is a smart way to save money. However, for industrial process lines, pump stations, or high-temperature service, the Lugged style is an investment in safety and maintenance efficiency.