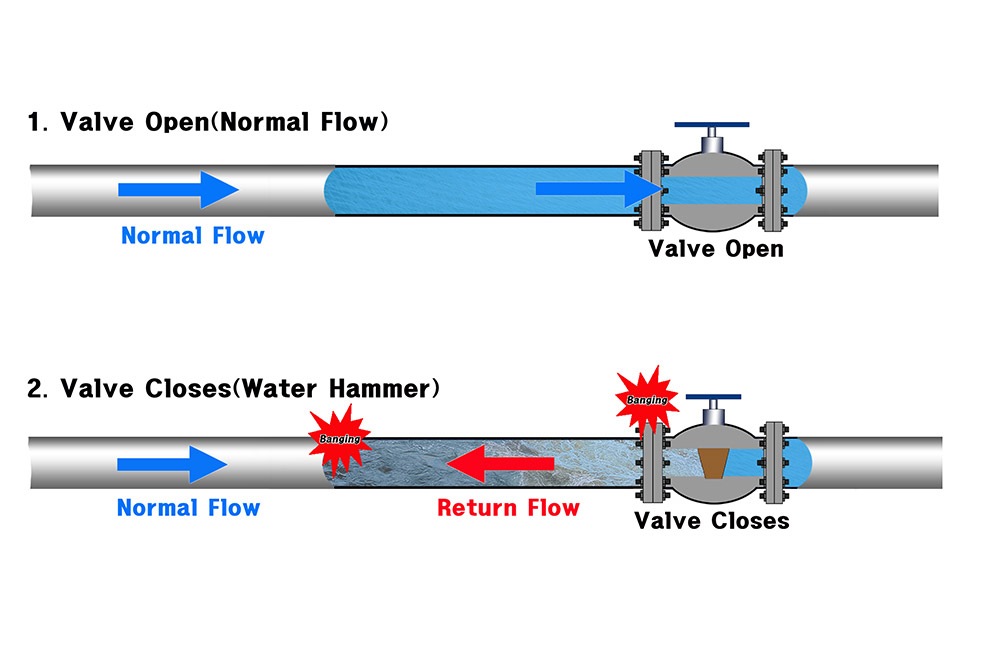

That loud, metallic “bang” you hear when a pump shuts off isn’t just a noise—it’s a physical warning. This phenomenon, known as water hammer, can generate instantaneous pressure fluctuations that are 5 to 10 times higher than the normal operating pressure.

If you are experiencing pipe vibration, damaged gaskets, or repeated pump failures, the culprit is likely a standard check valve that closes too slowly. This article explores how Non-Slam Check Valves eliminate water hammer before it starts.

Table of Contents

Toggle1. What Causes Water Hammer in Check Valves?

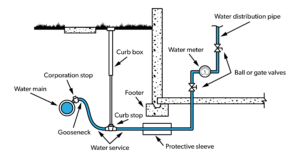

Water hammer occurs due to the sudden reversal of flow.

When a pump stops, the column of water in the pipe begins to reverse direction due to gravity. If you use a traditional Swing Check Valve, the disc is slow to react. By the time the disc slams shut, the reverse flow has already gained significant velocity.

The result? The moving water hits the closed valve like a liquid sledgehammer, sending a shockwave through the entire piping system.

2. The Solution: The Non-Slam (Silent) Design

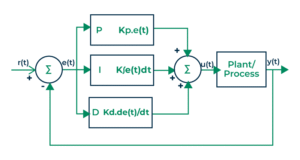

Unlike a swing check valve that relies on gravity and backflow to close, a Non-Slam Check Valve is engineered to be “proactive.”

Spring-Assisted Closure: It features a heavy-duty internal spring that constantly exerts pressure on the disc.

Pre-emptive Sealing: The spring is designed to push the disc back to the seat the exact millisecond the pump stops—before the water has a chance to reverse direction.

The Result: Since there is zero reverse flow velocity when the valve closes, there is no collision, no shockwave, and no noise.

3. Comparing Swing Check vs. Non-Slam Performance

| Feature | Standard Swing Check | Non-Slam Check Valve |

| Closing Speed | Slow (Relies on gravity) | Instant (Spring-loaded) |

| Noise Level | Loud “Slam” or “Bang” | Silent Operation |

| Pressure Surge | High (Potential for pipe burst) | Minimal to None |

| Maintenance | High (Wear on hinge pins/seats) | Low (Simplified internal parts) |

| Best Application | Low-head, gravity-fed lines | High-rise risers, VFD pumps |

4. Why You Should Invest in Non-Slam Technology

While a Non-Slam Check Valve may have a higher upfront cost than a basic swing check, it offers significant long-term savings:

A. Protect Your Expensive Pumps

Water hammer shockwaves travel backward, hitting the pump’s impeller and seal. This is a leading cause of broken shafts and mechanical seal leaks. A Non-Slam valve acts as a “shield” for your most expensive equipment.

B. Reduce Pipe Fatigue

The constant vibration and “banging” caused by standard check valves lead to fatigue cracking at pipe joints and supports. Eliminating the slam extends the overall life of your infrastructure.

C. System Safety

In high-pressure industrial environments, water hammer can cause catastrophic failure of pipe fittings, posing a major safety risk to personnel.

5. Critical Selection Tip: Sizing for Flow, Not Pipe Size

A common engineering mistake is sizing a Non-Slam Check Valve based solely on the pipe diameter.

Expert Advice: To ensure the silent feature works, the valve must be “fully open” during normal flow. If the flow rate is too low for the valve size, the disc will “flutter” against the spring, causing premature wear. Always provide your flow rate (GPM/m³h) to your supplier to ensure correct spring tension.

Conclusion: Stop the Slam, Save the System

If your facility is suffering from the noise and damage of water hammer, changing your gaskets or tightening your supports won’t fix the root cause. The only permanent solution is to upgrade to a Non-Slam Check Valve. It is the most cost-effective insurance policy you can buy for your piping system.