The Y-Strainer is the first line of defense for your expensive pumps, flow meters, and control valves. However, its effectiveness depends entirely on one thing: Gravity.

In the field, we often see Y-strainers installed in positions that make them impossible to clean or, worse, cause debris to fall back into the system during maintenance. If you are planning a vertical pipeline installation, you need to understand the “Dirty Truth” about orientation before you weld that flange.

Table of Contents

Toggle1. Horizontal Installation: The Gold Standard

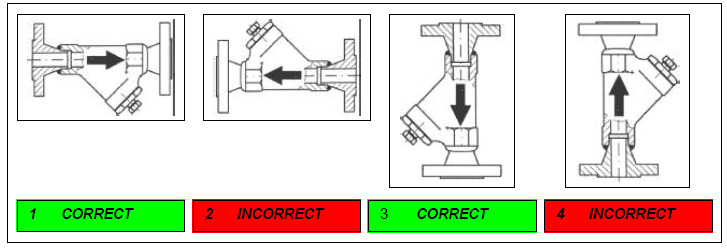

In 90% of industrial applications, the horizontal position is the preferred choice for Y-strainers.

The Rule: The “leg” (the part containing the screen) must point downward.

The Reason: This allows gravity to pull the filtered debris into the collection leg. When you open the blow-off valve or remove the cover, the trash stays in the leg and doesn’t flush back into the main pipe.

Pro Tip: Ensure there is enough “pull-out clearance” below the strainer. There’s nothing worse than realizing you can’t remove a 24-inch screen because the floor is too close.

2. The “Vertical Up” Trap: Is It Allowed?

Can you install a Y-strainer on a vertical pipeline? The answer is yes, but only if the flow is moving DOWNWARD.

When Flow Moves UP (The Danger Zone)

If your fluid is moving from bottom to top (Vertical Up), installing a Y-Strainer is a major mistake.

Why? Gravity pulls the debris to the bottom of the pipe, not into the strainer’s collection leg.

The Result: The debris accumulates at the lowest point of your piping system (likely at the pump outlet), while the strainer remains empty. This renders the filter useless and increases the risk of a pump-clogging “slug” of debris during startup.

When Flow Moves DOWN (The Correct Vertical Way)

Vertical installation is only acceptable when the flow moves from top to bottom.

The Rule: The “leg” must point downward following the direction of flow.

The Benefit: Gravity helps the debris settle into the leg, just like in a horizontal installation.

3. The “Dirty” Truth: Maintenance Disasters

The biggest problem with vertical Y-strainer installation (even with downward flow) happens during cleaning.

In a horizontal line, when you remove the cap, the debris sits in the basket. In a vertical line, the moment you loosen the cover, any loose debris that hasn’t fully settled in the leg can fall straight down the pipe and into your downstream equipment.

Expert Solution: If you must install vertically, always install an isolation valve both upstream and downstream of the strainer. Close both before opening the filter to ensure no “stray” debris escapes into the system.

4. Comparison Table: Orientation Checklist

| Installation Style | Flow Direction | Leg Position | Debris Collection | Maintenance Ease |

| Horizontal | Any | Must point DOWN | Excellent | Easy |

| Vertical Down | Top-to-Bottom | Points Down | Good | Moderate (Risk of fall-through) |

| Vertical Up | Bottom-to-Top | Any | Fails | Impossible |

| Steam Line | Horizontal | Horizontal (Side) | Good | Prevents Water Hammer |

5. Special Case: Steam Systems (The 90-Degree Rule)

If you are installing a Y-Strainer in a Steam Line, the rules change.

The Rule: Install the strainer horizontally, but turn the leg to the SIDE (90 degrees) instead of pointing down.

Why? If the leg points down, it acts as a “pocket” where condensate (water) collects. When steam hits that water, it causes Water Hammer. Turning the leg sideways allows the steam to pass without creating a water trap.

Conclusion: Gravity Always Wins

When selecting a location for your Y-type strainer, always visualize where the dirt will go when the flow stops. If it doesn’t stay in the strainer leg, you’ve chosen the wrong spot. Stick to horizontal lines whenever possible, and strictly avoid “vertical up” flow.