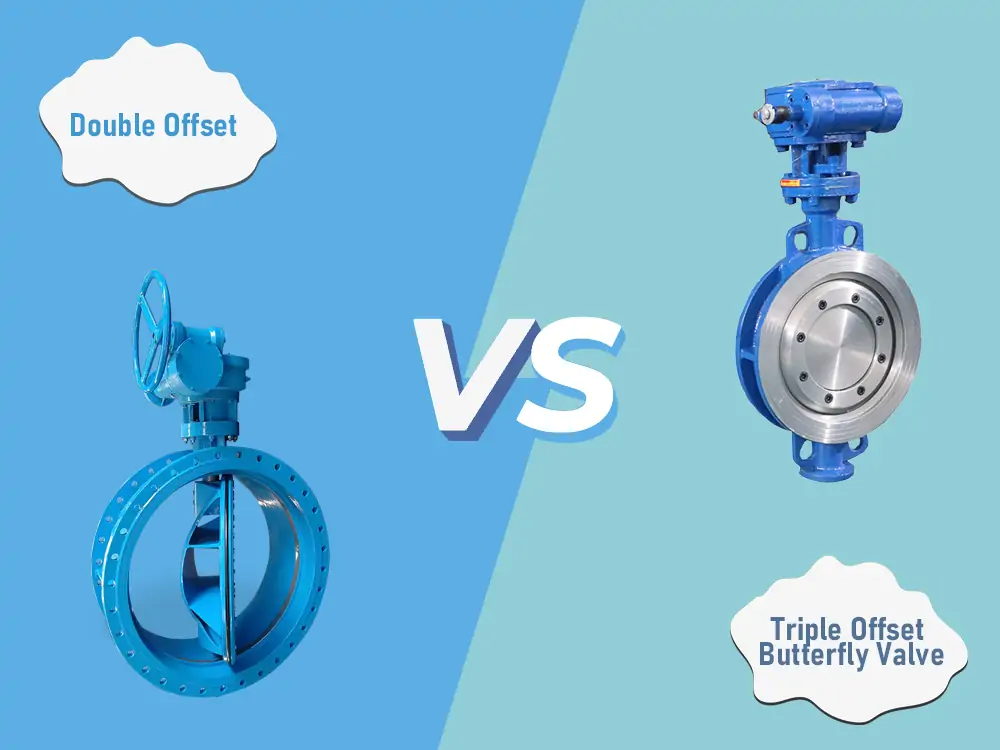

When a standard rubber-lined butterfly valve fails, engineers look to “High-Performance” options. However, the term “High-Performance” can be misleading. In the valve industry, there is a massive jump in technology and cost between a Double Offset (High-Performance) and a Triple Offset valve.

Choosing the wrong one could mean a valve that leaks in six months or, conversely, overspending thousands of dollars on a valve your system doesn’t actually need. This guide explains the mechanical evolution from Double to Triple offset.

Table of Contents

Toggle1. High-Performance (Double Offset) Butterfly Valve

The Double Offset design is the standard for most industrial process lines.

The Design: The shaft is offset from the centerline of the disc and the seating surface. This creates a “camming” action, where the disc lifts off the seat immediately upon opening, reducing friction.

The Seal: Usually features a Soft Seat (PTFE, RTFE, or PEEK).

The Advantage: Provides a “bubble-tight” seal (Class VI) and handles much higher pressures than standard concentric valves.

Best Use Case: Chilled water, chemicals, and hydrocarbons where zero-leakage is required but temperatures are below 250°C.

2. Triple Offset Valve (TOV): The Zero-Leakage Metal Seal

The Triple Offset adds a third geometric offset: the axis of the seat cone is angled off the centerline of the valve.

The Design: This third offset creates a “right-angle” seating geometry. The disc makes contact with the seat only at the final point of closure.

The Seal: Metal-to-Metal. Because there is no rubbing or friction during the stroke, the metal surfaces don’t wear out.

The Advantage: It is the only butterfly valve design that achieves Class VI Zero-Leakage with a Metal Seat.

Best Use Case: High-pressure steam (above 150 PSI), refinery “coker” units, abrasive slurries, and Fire-Safe applications where temperatures exceed 400°C.

3. Core Comparison: Double vs. Triple Offset

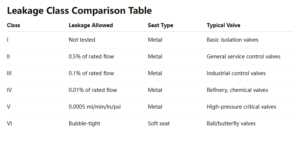

| Feature | Double Offset (HPBV) | Triple Offset (TOV) |

| Seat Material | Typically Soft (PTFE / PEEK) | Laminated Metal / Solid Metal |

| Sealing Geometry | Cam-action (Interference seal) | Non-rubbing (Torque-seated) |

| Shutoff Class | Class VI (Bubble-Tight) | Class VI (Zero-Leak Metal Seal) |

| Max Temperature | Limited by soft seat (~250°C) | Extremely High (600°C+) |

| Service Life | Good (Minor seat wear) | Excellent (Zero seat wear) |

| Cost | Mid-Range ($\$$$$) | Premium ($\$$$$\$$$$) |

4. The Engineer’s Rule: When to Upgrade?

Choose Double Offset (High-Performance) if:

You need Zero-Leakage in a clean liquid or gas system.

Your temperature is within the limits of PTFE or PEEK.

You need high-cycle life (the camming action reduces wear significantly compared to cheap valves).

Upgrade to Triple Offset (TOV) if:

Metal-to-Metal Sealing is mandatory: For example, in abrasive media that would shred a PTFE seat.

Extreme Temperatures: You are handling high-pressure steam or molten salt.

Fire-Safety: You need the valve to remain sealed even if the entire plant is on fire (TOVs are inherently fire-safe).

Fugitive Emissions: TOVs are the gold standard for preventing toxic gas leaks in chemical plants.

5. Why Triple Offset is a “Problem Solver”

The biggest advantage of the TOV is that it replaces the Gate Valve in many large-diameter applications.

Weight Saving: A 24-inch TOV is 70% lighter than a 24-inch Gate Valve.

Operation: It is much faster to close a quarter-turn TOV in an emergency than it is to crank a Gate Valve 50 times.

Conclusion

While the Double Offset (High-Performance) butterfly valve is the “workhorse” for most industrial fluids, the Triple Offset is the specialist for “Severe Service.” If your system involves high heat, grit, or high-pressure steam, the Triple Offset is not an “expensive option”—it is the only safe option.