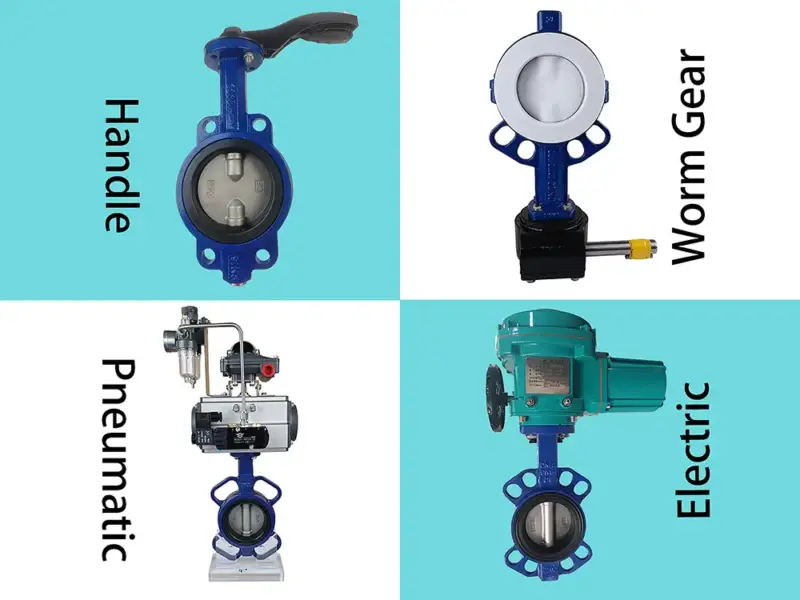

Automating a butterfly valve is more than just bolting a motor to a stem. Because butterfly valves are quarter-turn (90-degree) devices, they have unique torque profiles—the force required to open the valve is different from the force required to close it.

Whether you are automating a large-diameter water valve or a high-performance chemical valve, choosing between a pneumatic rack-and-pinion actuator and an electric rotary actuator is the most critical factor for system uptime.

Table of Contents

Toggle1. The Torque Challenge: Why It Matters for Butterfly Valves

Unlike ball valves, butterfly valves are “interference-seated.” The disc must compress into the rubber or PTFE seat to seal.

Breakaway Torque: The highest force is needed at the moment of opening.

Hydrodynamic Torque: As fluid flows past the disc, it creates a “wing” effect that can try to slam the valve shut or open.

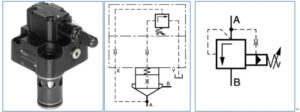

The Selection Rule: * Pneumatic actuators excel at providing a “burst” of high torque at the start of the stroke (especially Scotch Yoke designs).

Electric actuators provide constant torque throughout the 90-degree turn.

2. Speed vs. Water Hammer

Pneumatic: Naturally fast. However, in large butterfly valves, closing too fast can cause Water Hammer. You must use speed controllers (silencers/regulators) to tune the pneumatic stroke.

Electric: Inherently slow and steady. This makes electric actuators excellent for large-diameter water lines where preventing pressure surges is more important than sub-second closure.

3. Fail-Safe Requirements (The “Spring” Factor)

In the event of a power or air failure, what should the butterfly valve do?

Pneumatic (Spring Return): By far the most reliable fail-safe. If air pressure is lost, a heavy-duty internal spring mechanically forces the valve to a safe position (Closed or Open).

Electric (Battery Backup): Electric actuators require expensive battery packs or “supercapacitors” to achieve a fail-safe position. For critical safety-line isolation, Pneumatic Spring-Return remains the gold standard.

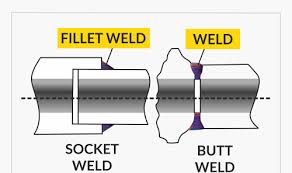

4. Mounting Standards: ISO 5211

When buying an actuator for your butterfly valve, you must check the ISO 5211 mounting pad.

Most modern butterfly valves feature a standardized square stem and bolt pattern.

Pro Tip: If your valve doesn’t match the actuator, you will need a custom Mounting Kit (Bracket & Coupler). Always provide the stem diameter and height to your supplier.

5. Quick Selection Table for Butterfly Valves

| Application | Recommended Actuator | Key Advantage |

| High-Cycle (Frequent opening/closing) | Pneumatic | Extremely high cycle life (millions of cycles). |

| Outdoor / Remote Sites | Electric | Only requires a power cable; no air lines needed. |

| Modulating (Throttling flow) | Electric | Higher precision without the need for a positioner. |

| Hazardous / ATEX Zones | Pneumatic | Intrinsically safe; no explosion-proof housing needed. |

| Large Diameter (Over 24″) | Pneumatic (Scotch Yoke) | Handles massive torque requirements economically. |

Conclusion

For most industrial process butterfly valves, Pneumatic Actuators offer the best balance of speed, safety, and cost. However, for remote water infrastructure or precise flow throttling, the Electric Actuator is the smarter, cleaner choice.