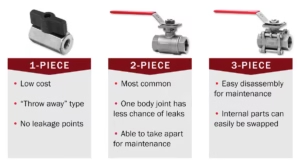

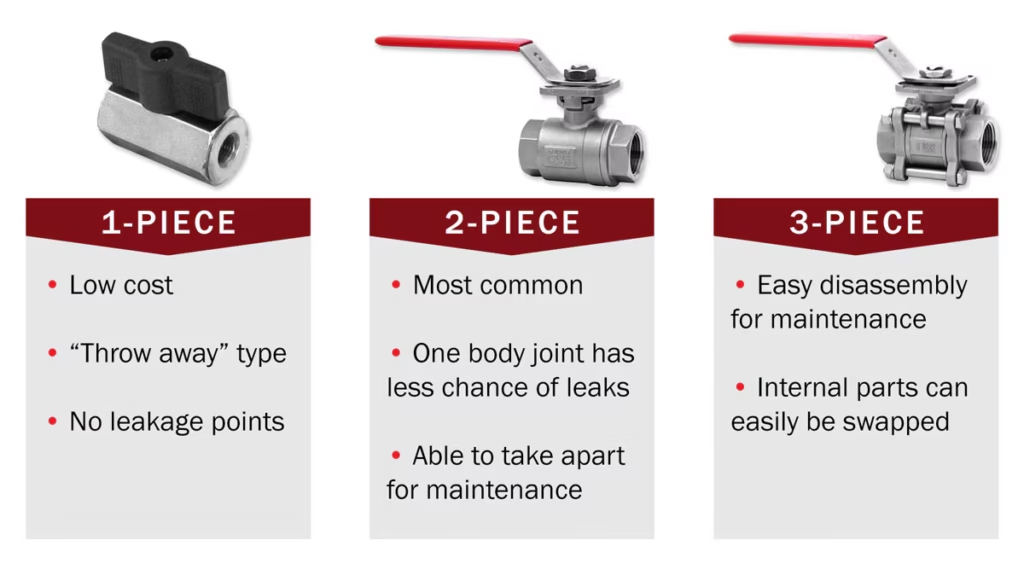

When sourcing ball valves, the price difference between a 1-piece, 2-piece, and 3-piece design can be confusing. To a buyer looking only at the initial quote, the 1-piece valve often looks like the winner.

However, in the industrial world, purchase price is only 10% of the true cost. The other 90% is hidden in installation, maintenance, and the most expensive word in manufacturing: Downtime. This guide breaks down the economics of ball valve construction to help you choose the best return on investment (ROI).

Table of Contents

Toggle1. 1-Piece Ball Valves: The “Disposable” Choice

The body is cast as a single solid piece. This reduces the number of leak paths but also limits the internal port size (Reduced Port).

The Economics: It is the cheapest to manufacture.

The Downside: It cannot be repaired. If a seat or seal fails, the entire valve must be cut out or unbolted and thrown away.

Best For: Non-critical, low-pressure utility lines (water, air) where the valve is rarely cycled and expected to be replaced rather than fixed.

2. 2-Piece Ball Valves: The Industry Standard

Consists of two body parts—one main body and one end cap. This allows for a Full Port design (no flow restriction).

The Economics: Offers the best balance between initial cost and performance.

The Downside: To replace the internal seals, the valve must be completely removed from the pipeline. This takes time and often requires re-aligning the pipes.

Best For: General industrial applications, chemicals, and water treatment where performance matters but maintenance isn’t a weekly occurrence.

3. 3-Piece Ball Valves: The “Maintenance King”

A 3-piece valve consists of a main center body and two end caps (usually bolted together).

The Game Changer: The “Swing-Out” Design. You can remove the bolts and swing the center body out of the line while the end caps remain attached to the pipes.

The Economics: High initial cost (approx. 30-50% more than 2-piece).

The ROI: * Zero Pipe Disturbance: You don’t have to disturb the pipe alignment to replace seats or seals.

Speed: A seal change that takes 2 hours on a 2-piece valve takes 15 minutes on a 3-piece valve.

Future-Proof: As seats wear out, you simply buy a “Repair Kit” instead of a new valve.

4. Financial Comparison: The “Hidden Cost” of a Leak

Imagine a failed valve on a critical production line.

| Cost Factor | 1-Piece Valve | 3-Piece Valve |

| Initial Purchase | $30 | $75 |

| Maintenance Labor | N/A (Must replace) | 15 mins ($20) |

| Replacement Labor | 2 Hours ($100) | $0 (Swing-out) |

| Production Downtime | High (System must be drained) | Minimal |

| Long-Term TCO | High (Repeated replacement) | Lowest (Infinite repairs) |

5. How to Choose Based on Your Budget?

Use 1-Piece if: You are on a strict CAPEX budget for a low-stakes utility project where valves are rarely used.

Use 2-Piece if: You need full flow and high performance but have the time to remove valves for occasional maintenance.

Use 3-Piece if: Time is money. If your production line costs $5,000 per hour in downtime, the $40 extra you spent on a 3-piece valve is the best insurance policy you’ll ever buy.

Conclusion: Stop Buying, Start Investing

Don’t let a low purchase price fool you into high maintenance costs. For critical process industries, the 3-piece ball valve is not an “expensive luxury”—it is a strategic asset that keeps your plant running.