If you hear a loud “BANG” every time your pump shuts down, your check valve is slamming. Many operators mistake this for a mechanical defect in the valve itself, but in reality, slamming is a symptom of a much larger physical phenomenon: Water Hammer.

Left unaddressed, these violent pressure surges can rupture pipe joints, shake supports loose, and even shatter pump casings. This guide explains why your check valve is slamming and how to choose a “Silent” alternative to protect your infrastructure.

Table of Contents

Toggle1. The Physics of the “Slam”

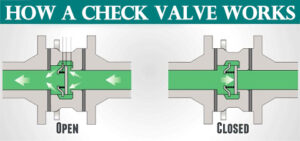

To fix the noise, you first have to understand the timing. A check valve slams when its disc (or flap) is too slow to close.

The Pump Stops: The fluid momentum forward begins to stall.

Reverse Flow Starts: Gravity or system pressure starts pushing the water backward toward the pump.

The Gap: Because the valve disc is still floating open, the reverse flow gains high velocity.

The Impact: The backward-rushing water catches the disc and slams it into the seat at high speed. That “bang” is the sound of moving water hitting a brick wall.

2. Reason #1: The Valve is “Oversized”

This is a common engineering mistake. If a check valve is too large for the actual flow rate, the disc never fully opens; it just “flutters” or hovers near the seat.

The Result: When the pump stops, the disc has a shorter distance to travel, but because it was unstable, it often gets caught in the reverse flow more violently.

The Solution: Size the valve based on flow velocity, not just the pipe size.

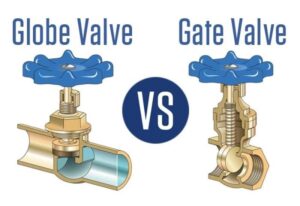

3. Reason #2: The Wrong Valve Type (Swing Check vs. Others)

The traditional Swing Check Valve is the biggest offender in slamming issues.

The Problem: The flap has to travel a long 90-degree arc to close. In vertical lines or high-head systems, the water reverses much faster than the flap can swing shut.

The Solution: For systems prone to water hammer, you need a Short-Stroke design.

4. How to Fix It: The “Silent” Alternatives

As a manufacturer, we recommend three ways to silence your system, depending on your budget:

A. Nozzle Check Valves (The Gold Standard)

These use a spring-assisted, lightweight disc that travels a very short distance. It closes before the flow can even begin to reverse.

The Result: True “Silent” operation and maximum protection for pumps.

B. Spring-Assisted Axial Check Valves

Similar to the nozzle check, these use a center-guided disc and a spring to force the valve shut the millisecond the pump loses power.

The Benefit: Works perfectly in both horizontal and vertical installations.

C. Rubber Disc (Tilt) Check Valves

The rubber-encapsulated disc is lighter and has a shorter travel path than a heavy steel swing flap. It absorbs some of the impact energy, making the close much quieter.

5. Quick Troubleshooting Checklist

| Symptom | Likely Cause | Recommended Action |

| Loud Bang at Pump Stop | Valve closes too slowly | Upgrade to Spring-Assisted or Nozzle Check. |

| Chattering/Vibration during flow | Valve is oversized | Recalculate Cv; use a smaller valve or a different design. |

| Repeated Seal Failure | Water hammer damage | Install a Surge Tank or a Silent Check Valve. |

Conclusion: Silence is Safety

A slamming check valve isn’t just an annoyance; it’s a warning. If your pipes are shaking, the internal components of your expensive pumps are taking a beating. Upgrading to a Spring-Assisted Silent Check Valve is the single most effective way to extend the life of your entire piping system.