In the world of industrial fluid control, ASTM A216 WCB is the “backbone” material. Whether it’s a massive refinery in the Middle East or a municipal water plant in Europe, WCB valves are the most common choice for non-corrosive service.

But why is WCB so dominant? When should you choose it over LCB or Stainless Steel? And how do you ensure the quality of a WCB casting? This comprehensive guide breaks down everything you need to know about the most versatile carbon steel in the valve industry.

Table of Contents

Toggle1. What is WCB? (Deciphering the Code)

The designation WCB comes from the ASTM A216 standard. Each letter tells a story about its engineering purpose:

W (Weldable): It is designed to be easily welded to pipelines during field installation.

C (Cast): It is produced through casting processes, allowing for complex valve body geometries.

B (Grade B): This refers to its medium strength level (Grade A is lower, Grade C is higher).

Equivalent Grades: * China: ZG230-450 / ZG280-520

Germany: GS-C25 / 1.0619

2. Chemical Composition & Mechanical Prowess

A high-quality WCB valve body is a balance of Carbon, Manganese, and Silicon.

Chemical Makeup (ASTM A216 Standard):

Carbon (C): ≤ 0.30% (Provides strength)

Manganese (Mn): 0.60% – 1.05% (Increases toughness)

Silicon (Si): ≤ 0.60% (Enhances deoxidation)

Impurity Control: Phosphorus (P) and Sulfur (S) are strictly kept under 0.04% to prevent welding cracks and brittleness.

Mechanical Properties:

| Property | Value |

| Tensile Strength | 485 – 655 MPa |

| Yield Strength | ≥ 250 MPa |

| Elongation | ≥ 22% |

| Impact Energy (-29°C) | ≥ 27 J |

3. The “Sweet Spot” for WCB: Working Conditions

The reason for WCB’s popularity is its wide “Comfort Zone.”

Temperature Range: -29°C to 427°C (-20°F to 800°F).

Pressure Rating: Typically used for ASME Class 150, 300, and 600.

Compatible Media: Water, saturated steam, non-corrosive oil, natural gas, and compressed air.

4. WCB vs. Other Materials: When to Upgrade?

The most common mistake in procurement is using WCB in the wrong environment. Use this “Stop-Light” system for your next project:

🟢 Use WCB When:

Handling neutral fluids (Water, Oil, Gas).

Temperature is stable between -29°C and 427°C.

Budget-efficiency is a priority.

🟡 Switch to LCB (Low Carbon Steel) When:

Operating in Arctic climates or cryogenic zones (below -29°C). WCB becomes brittle at low temperatures.

🔴 Switch to CF8/CF8M (Stainless Steel) When:

Handling corrosive acids, alkalis, or seawater.

Purity is critical (Food & Pharma).

Operating temperatures exceed 427°C (where WCB begins to oxidize).

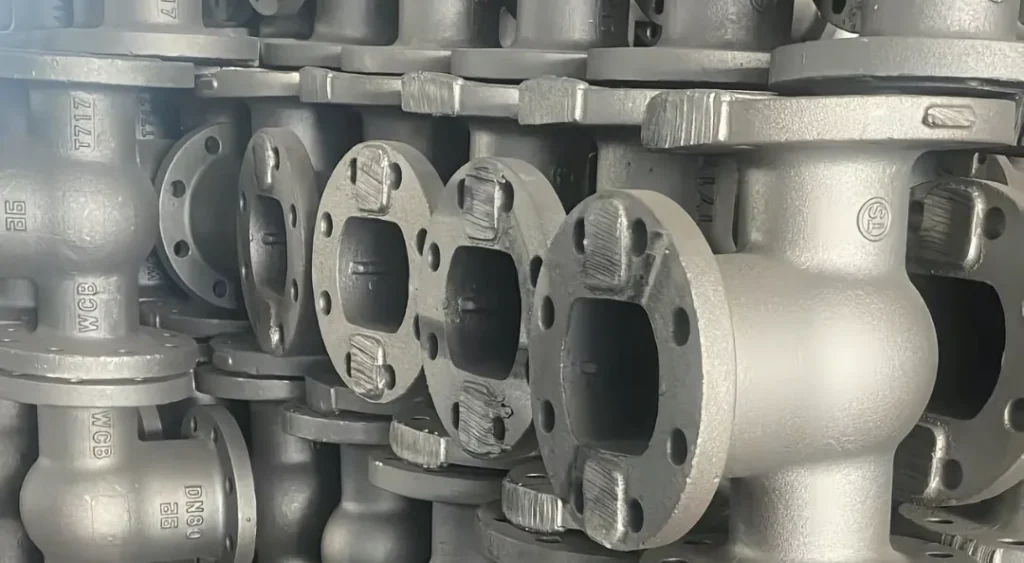

5. 3 Quality Red Flags to Watch For (Buyer’s Checklist)

As a manufacturer, we know that not all WCB castings are equal. To avoid premature valve failure, inspect for these 3 things:

Casting Defects: Look for “Sand Holes” or “Porosity” on the surface. High-quality WCB should undergo MT (Magnetic Particle) or UT (Ultrasonic) testing.

Heat Treatment Records: Without proper Normalizing, WCB will have internal stresses that lead to body cracking under pressure.

Wall Thickness: Low-cost suppliers often thin the valve walls to save metal. Ensure your valve meets API 600 or ANSI B16.34 thickness standards.

6. Real-World Applications

WCB valves are the workhorses in:

Power Plants: Boiler feedwater and steam isolation.

Oil & Gas: Midstream pipelines for crude and refined products.

HVAC: Large-scale commercial heating and cooling systems.

Refining: Non-corrosive cracking and distillation stages.

Conclusion: The Best Value for Your Pipeline

The WCB valve remains the industry standard because it offers the perfect marriage of mechanical strength and cost-efficiency. By understanding its temperature and chemical limits, you can design a system that is both safe and economical.