Table of Contents

ToggleThe Fundamental Difference: Manufacturing Process

While both materials are chemically similar carbon steels, their manufacturing DNA defines their mission in a piping system:

WCB (ASTM A216): A Cast Steel. Molten steel is poured into a mold to form the shape.

A105 (ASTM A105): A Forged Steel. Solid steel is hammered or pressed into shape under extreme heat and pressure.

1. Structural Integrity: Why Forging Wins on Strength

A105 (Forged): The forging process mechanically deforms the metal, creating a continuous grain flow. This eliminates internal porosity and voids, making A105 significantly more resistant to fatigue, impact, and high-pressure surges.

WCB (Cast): During the cooling of molten metal, tiny gas pockets (Porosity) or “sand holes” can form. While high-quality foundries use non-destructive testing (NDT) to manage this, a casting’s internal density is inherently lower than a forging’s.

2. Size and Geometry: Why Casting Wins on Economy

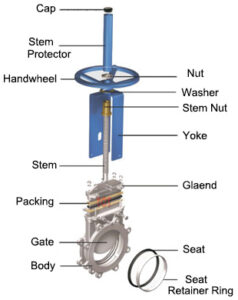

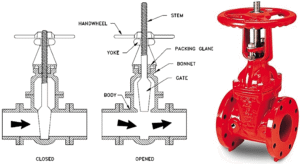

WCB (Large & Complex): The biggest advantage of casting is geometric freedom. For valves larger than 2 inches (DN50), especially complex Gate or Globe bodies, casting is the only cost-effective method.

A105 (Small & Simple): Forging costs increase exponentially with size. Therefore, A105 is primarily used for small-diameter valves (DN50 and below), flanges, and fittings.

3. Technical Comparison Table

| Feature | ASTM A216 WCB (Cast) | ASTM A105 (Forged) |

| Manufacturing | Poured into molds (Casting) | Mechanically pressed (Forging) |

| Typical Size | DN50 (2″) and above | DN50 (2″) and below |

| Internal Defects | Potential for sand holes/porosity | Virtually none (Dense structure) |

| Strength | Balanced | Superior (High impact resistance) |

| Welding | Excellent | Excellent |

| Cost | Economical for large sizes | Higher for large sizes |

4. Critical Selection Scenarios: Which to Choose?

Scenario A: High-Pressure Power Systems

In Class 1500 or Class 2500 ultra-high-pressure steam lines, engineers almost always mandate A105 Forged Steel. At these pressures, even a microscopic casting defect in a WCB body could escalate into a catastrophic crack or blowout.

Scenario B: Large Midstream Oil Pipelines

In a 24-inch crude oil pipeline, manufacturing a forged body is technically difficult and prohibitively expensive. In this case, a high-quality WCB Casting subjected to 100% Radiographic Testing (RT) is the industry standard for balancing safety and budget.

5. Quality Checklist for Global Buyers

The “Cast-as-Forged” Scam: Some low-end suppliers sell castings and claim they are forgings.

How to spot it: Check the surface. Forgings have a smoother, refined finish with no “sand-like” texture. Verify the hardness; A105 is usually more uniform and slightly harder than WCB.

NDT Requirements: If you choose WCB for critical service (like medium-pressure steam), always demand RT (X-ray) or UT (Ultrasonic) reports to ensure the internal casting is sound.

Heat Treatment: Ensure your WCB has been Normalized. Without proper heat treatment, cast steel retains internal stresses that lead to body failure under thermal cycling.

Conclusion: The Selection Logic

Large Bore (DN > 50mm) + Low/Medium Pressure = Choose WCB (Best ROI).

Small Bore (DN ≤ 50mm) + High Pressure/Critical Service = Choose A105 (Safety First).