Table of Contents

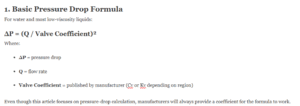

ToggleThe Hidden Danger of Oxygen Service

In most industrial applications, a trace of oil or grease on a valve seat is considered a minor lubrication benefit. However, in an Oxygen Service environment, it is a ticking time bomb.

When high-purity oxygen comes into contact with even microscopic amounts of hydrocarbons (oil, grease, or organic fibers), it can trigger spontaneous combustion—even without an external spark. This is why Medical Gas Valves must undergo a specialized cleaning process that goes far beyond “industrial clean.”

1. The Physics of Combustion: Why “Oil-Free” is Mandatory

Oxygen is not flammable itself, but it is a powerful oxidizer that drastically lowers the ignition temperature of other materials.

The Risk: In a pressurized pipeline, the friction of gas flow or the heat of compression can ignite residual lubricants.

The Consequence: A fire inside a Medical Gas Ball Valve can lead to a catastrophic explosion, endangering hospital patients and destroying expensive life-support equipment.

The Solution: Every component must be Oil-Free. This is why standards like CGA G-4.1 and ASTM G93 were established.

2. Our Precision Degreasing Process: From “Dirty” to “Oxygen-Safe”

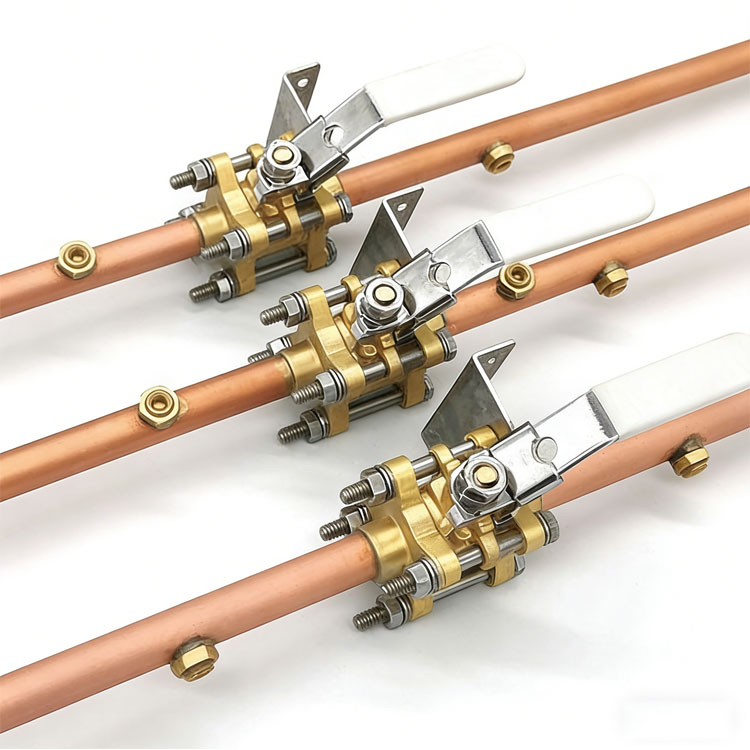

At TOT Valve, we follow a multi-stage cleaning protocol to ensure every Oxygen Ball Valve meets the highest safety thresholds.

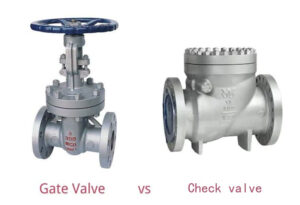

Step 1: Pre-Inspection

Before cleaning, valves are disassembled. We inspect all internal surfaces of the SS316L body and ball for burrs or slag that could trap contaminants.

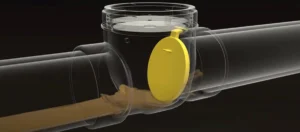

Step 2: Ultrasonic Degreasing

Components are submerged in an Ultrasonic Cleaning Tank with specialized, non-ozone-depleting aqueous detergents. High-frequency sound waves create cavitation bubbles that scrub every microscopic pore, removing all hydrocarbons and metallic particles.

Step 3: High-Purity Water Rinse

Parts are rinsed with deionized water to ensure no detergent residue is left behind.

Step 4: UV Light Inspection (Black Light Test)

This is the ultimate quality check. Our technicians inspect the parts under Ultraviolet (UV) Light. Hydrocarbons fluoresce under UV; if any glow is detected, the part returns to Step 1.

3. Packaging: Maintaining Purity Until the Moment of Use

Cleaning a valve is useless if it gets contaminated during shipping. Our Medical Gas Valves are handled with the “Cleanroom Protocol”:

Drying: Parts are dried using oil-free nitrogen or filtered air.

Assembly: Re-assembled by technicians wearing lint-free gloves and suits in a controlled environment.

Vacuum Sealing: Each valve is double-bagged in transparent polyethylene and vacuum-sealed.

Labeling: Every bag is marked with “CLEANED FOR OXYGEN SERVICE – DO NOT OPEN UNTIL READY FOR USE.”

4. Why Compliance with NFPA 99 and CGA G-4.1 Matters

When you specify an Oxygen Ball Valve from a professional manufacturer, you aren’t just buying a piece of hardware; you are buying a certified process.

NFPA 99: The standard for Health Care Facilities, ensuring gas systems are safe for patients.

CGA G-4.1: The definitive guide for cleaning equipment for oxygen service.

Failure to use certified Oil-Free Valves in these environments can result in failed safety audits, insurance denials, and, most importantly, life-threatening accidents.

Conclusion: Safety is Not an Option

At TOT Valve, we treat every Medical Gas Valve with the gravity it deserves. Our investment in ultrasonic cleaning technology and cleanroom packaging ensures that when you turn the handle on a TOT oxygen valve, you are operating the safest equipment on the market.