In the high-stakes world of oil, gas, and petrochemicals, standards are the “Safety Guard.” The American Petroleum Institute (API) provides the technical blueprint that ensures every valve—from a small forged gate valve to a massive pipeline ball valve—performs reliably under extreme pressure.

This comprehensive guide serves as your API Valve Bible, covering everything from the API standard list and NFPA compliance to the critical differences in valve engineering.

Table of Contents

TogglePart 1: What is the American Petroleum Institute (API)?

The American Petroleum Institute (API) is the primary trade association for the U.S. oil and natural gas industry. Since 1919, API petroleum standards have become the global language for energy equipment.

What does the American Petroleum Institute do?

The API’s core mission is to promote safety through standardization. As an ANSI-accredited organization, API develops API guidelines that are used by engineers worldwide to ensure:

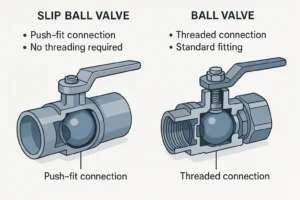

Interchangeability: Valves from different ball valve manufacturers fit the same pipelines.

Structural Integrity: Mandating wall thicknesses that prevent catastrophic ruptures.

Environmental Safety: Reducing fugitive emissions via API 622 standards.

Part 2: The API Valve Standards List (Quick Reference)

For procurement managers and engineers, understanding the API list of standards is essential. Below is the technical breakdown of the most common American Petroleum Institute codes:

| Standard | Description | Primary Application |

| API 6D | Specification for Pipeline Valves | Midstream oil and gas transport. |

| API 600 | Steel Gate Valves (Bolted Bonnet) | Heavy-duty refinery and downstream service. |

| API 602 | Compact Forged Steel Valves | Small-bore high-pressure piping. |

| API 607 | Fire Test for Quarter-turn Valves | Fire-safe certification for ball/butterfly valves. |

| API 598 | Valve Inspection & Testing | The universal testing protocol for all API valves. |

Part 3: API 600 vs. Standard Gate Valves: The Safety Gap

Many buyers ask: “Why pay more for an API 600 valve?” The difference lies in the American Petroleum Institute specifications for durability.

Wall Thickness: API 600 mandates a thicker body than standard ASME B16.34 valves, providing a superior corrosion allowance.

Stem Diameter: API 600 valves feature heavier stems to prevent bending under high torque.

Stuffing Box Depth: Designed for better packing compression to meet fugitive emission requirements.

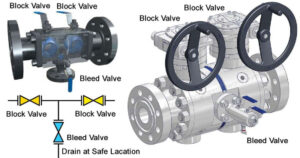

Part 4: Valve Fire-Safety: API meets NFPA Standards

In hazardous environments, valves must comply with both API and NFPA (National Fire Protection Association) guidelines.

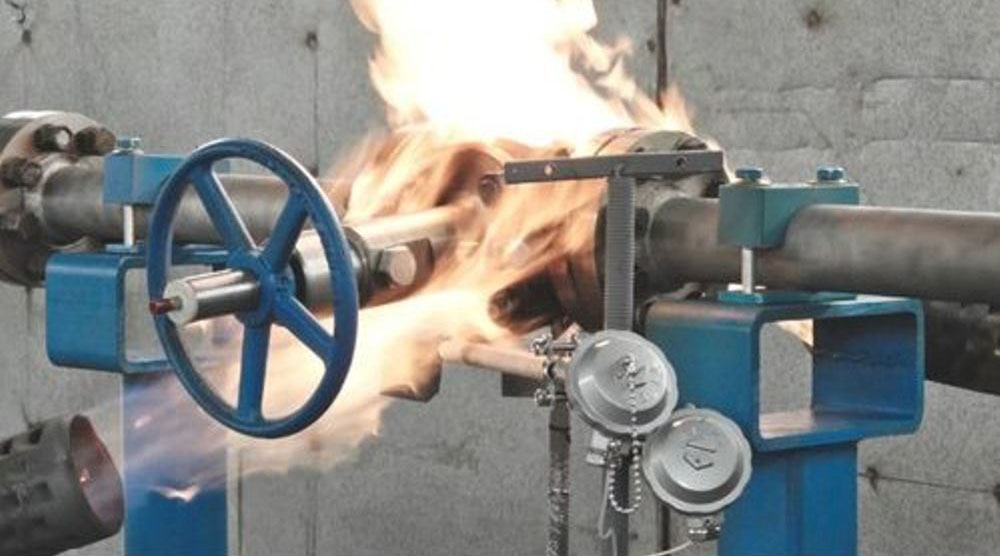

What is NFPA? The National Fire Protection Association sets the safety codes for fire prevention. For valves, NFPA standards typically require API 607 or API 6FA certified “Fire-Safe” designs.

The API 607 Fire Test: The valve is subjected to temperatures up to 980°C (1800°F).

The Goal: To ensure the valve maintains a metal-to-metal seal even after soft seats are destroyed, preventing the fire from gaining more fuel.

Part 5: The Value of API Certification (Trust & ROI)

Obtaining the American Petroleum Institute API monogram is a rigorous process. While API petroleum standards may increase the initial cost by 15-20%, the Return on Investment (ROI) is clear:

Lower Maintenance: Higher grade trim (like Stellite) reduces the frequency of overhauls.

Global Access: Most international tenders (Aramco, Shell, etc.) require API-certified products as a mandatory entry requirement.

Risk Mitigation: Using certified valves reduces the legal and environmental liability for plant operators.

Part 6: Engineering Support: PSV Sizing & Calculations

Beyond selecting the right API code, ensuring the correct size is vital—especially for Pressure Relief Valves (PSV).

Instead of relying on an unverified pressure relief valve sizing calculator excel, we recommend following API 520/521 protocols. Our team provides professional PSV sizing software reports to ensure:

Zero Chattering: Avoiding rapid valve cycling that destroys seats.

Accurate Orifice Selection: Matching the API 526 size chart to your flow requirements.

Conclusion: Partnering with an API-Expert Manufacturer

Navigating the American Petroleum Institute standards is complex, but it is the only way to ensure 100% operational safety. At TOT Valve, we don’t just manufacture valves; we engineer compliance.