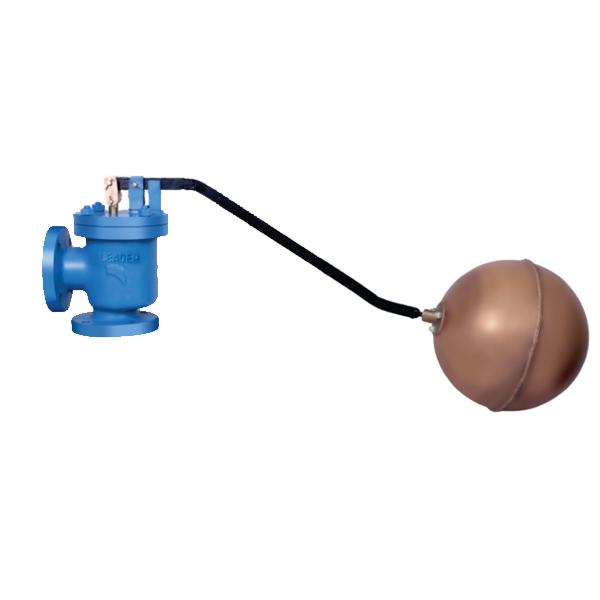

A float valve is the “silent guardian” of fluid level control. Whether in a cooling tower, a high-pressure reservoir, or a simple water tank, a correctly installed float valve prevents catastrophic overflows and costly water waste.

However, a “functional” installation isn’t always a “reliable” one. Improperly mounted valves often suffer from leaks, “chattering” noises, or mechanical sticking. This professional guide provides a step-by-step technical workflow for installing a float valve correctly the first time.

Table of Contents

Toggle1. Pre-Installation: Matching the Valve to Your System

Before drilling, ensure your valve specifications align with your operational environment.

Pressure Rating: Standard valves may fail in high-pressure systems (> 100 psi). For high-pressure applications, ensure you use an Equilibrium Float Valve designed to balance the inlet pressure.

Material Compatibility: Use SS316 float valves for corrosive chemicals or salt water, and plastic/brass for general potable water.

Inlet Size: Common sizes include 1/2″, 3/4″, and 1″ NPT/BSPP. Ensure your supply pipe matches the valve orifice.

2. Tools & Materials Checklist

Adjustable Wrench & Pipe Wrench

PTFE (Teflon) Thread Seal Tape

Drill with Hole Saw (if creating a new inlet)

Sealing Gaskets (EPDM or Viton)

Spirit Level (to ensure horizontal alignment)

3. Step-by-Step: New Float Valve Installation

Step 1: System Isolation and Tank Preparation

Shut off the main water supply and drain the tank below the mounting point. Clean the interior wall around the inlet to ensure the gasket creates a 100% airtight seal.

Step 2: Drilling and Deburring

If the tank lacks an opening, drill the inlet hole at the desired height.

Pro Tip: Always deburr the edges of the hole. Sharp plastic or metal shards can tear the sealing gasket, leading to “invisible” leaks through the tank wall.

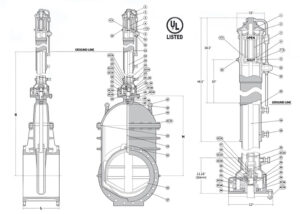

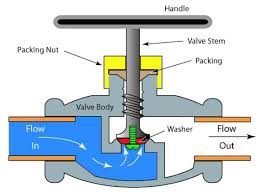

Step 3: Mounting the Valve Body

Insert the valve shank through the hole from the inside. Place the rubber gasket on the inside of the tank wall to utilize the water pressure for a tighter seal. Secure the valve from the outside using the backnut.

Warning: Do not over-tighten. Over-tightening can crack the tank wall or distort the gasket.

Step 4: Thread Sealing and Supply Connection

Wrap the male threads of your supply line with PTFE tape (wrap 5-7 times in the direction of the threads). Connect the pipe to the valve inlet.

Engineering Check: Ensure the external piping is supported. The weight of the pipe should not hang on the valve body.

Step 5: Float Arm and Ball Assembly

Attach the float arm to the valve lever. Screw the buoyant ball onto the end of the arm. Ensure the arm moves vertically without rubbing against the tank wall or hitting any internal baffles.

4. Precision Adjustment: Setting the Shut-off Level

The most critical part of float valve installation is the final adjustment.

The Initial Test: Slowly open the water supply.

The Setpoint: Watch as the water rises. If the water stops too early or too late, adjust the float arm.

Adjustment Method: * Bent-Arm Valves: Slightly bend the brass arm to change the float angle.

Screw-Adjust Valves: Loosen the wing nut at the pivot point, reposition the arm, and re-tighten.

The “Splash Zone”: Ensure the shut-off level is at least 2 inches below the overflow pipe to account for surface ripples.

5. Troubleshooting Common Installation Failures

Issue: The Valve Won’t Shut Off (Continuous Leak)

Cause: Debris (sand/pipe scale) trapped in the valve seat.

Fix: Disassemble the valve head and flush the seat with clean water.

Issue: Water Hammer (Banging Noise)

Cause: High pressure or waves causing the float to “bounce.”

Fix: Install a Stilling Well (a perforated pipe around the float) to stabilize the water surface, or install an air chamber/water hammer arrestor in the supply line.

Issue: Sticking Arm

Cause: Misalignment or mineral buildup.

Fix: Ensure the valve is perfectly horizontal using a spirit level. For hard water, apply a food-grade lubricant to the pivot pin.

6. Maintenance Checklist for Longevity

To prevent sudden failure, perform an annual inspection:

Check the Float Ball: Shake it to see if water has leaked inside (waterlogging).

Inspect the Washer: Replace the rubber seal if it appears brittle or cracked.

Clear the Orifice: Ensure no mineral scale is restricting the flow.

Conclusion

A successful float valve installation requires more than just tightening a nut. By focusing on correct orientation, pressure matching, and precise level adjustment, you ensure a maintenance-free system for years to come.