Table of Contents

ToggleThe Engineering Dilemma

In water works and industrial piping, a common question arises during the planning of a new branch connection: “Can we just use a standard gate valve for the tap to save costs?”

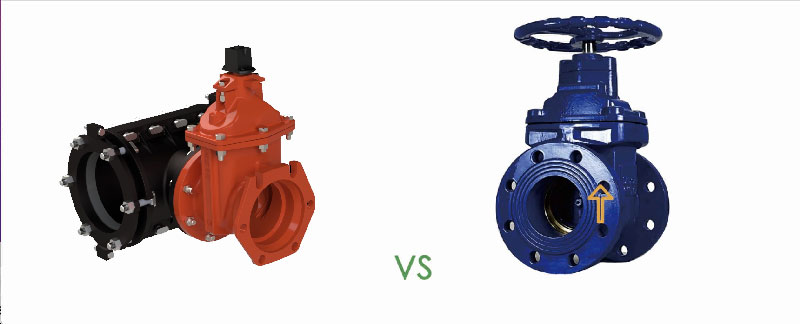

While a tapping valve and a standard gate valve may look similar at a glance, using the wrong one during a wet tap (live pipe drilling) can lead to catastrophic equipment damage and failed seals. This guide breaks down the critical differences between a tapping valve and a standard gate valve.

1. The “Bore” Difference: Oversized vs. Standard

The most significant technical difference is the internal diameter of the seat.

Tapping Valve: These are designed with an oversized seat opening (Full Bore). If you have a 6″ tapping valve, the actual opening is slightly larger than 6″.

Why? This provides enough clearance for the Tapping Machine’s cutter to pass through the valve body without touching or scarring the valve seats.

Standard Gate Valve: A standard 6″ gate valve has an opening that is exactly (or slightly less than) 6″.

The Risk: If you attempt a wet tap through a standard valve, the cutter will likely hit the valve seat, destroying the valve’s ability to ever seal again and potentially breaking the expensive cutting tool.

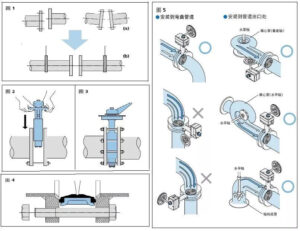

2. Alignment and Centering (The “Lip”)

A tapping sleeve and valve must be perfectly aligned to ensure a leak-proof cut.

Tapping Valve: Features a specialized Alignment Lip (a raised circular ridge) on the flange that connects to the tapping sleeve. This “lip” fits perfectly into the sleeve’s recess, ensuring the valve is centered exactly over the pipe.

Standard Gate Valve: Standard valves have flat-faced or raised-face flanges meant for pipe-to-pipe connection. They lack the centering mechanism required to align with a tapping saddle or sleeve. Without this alignment, the cutter may strike the side of the valve.

3. Tapping Valve vs. Insertion Valve

Another common point of confusion is the insertion valve. While both allow work on live mains, their purposes are different:

| Feature | Tapping Valve | Insertion Valve |

| Primary Goal | Adding a New Branch (Lateral) | Adding a New Shut-off Point |

| Pipe Modification | A “Coupon” (piece of pipe) is removed | A section of the pipe is slotted/machined |

| Equipment | Needs a Tapping Sleeve & Machine | Needs specialized Insertion Equipment |

If your goal is to add a fire hydrant or a new line to a building, you need a tapping valve. If you need to fix a broken section of a main line without shutting off the whole neighborhood, you need an insertion valve.

4. Comparison Summary: Tapping Valve vs. Standard Valve

| Technical Spec | Tapping Valve | Standard Gate Valve (Resilient Wedge) |

| Internal Clearance | Oversized (Cutter-friendly) | Exact Pipe Size |

| Flange Design | Alignment Lip for Sleeves | Standard Flat/Raised Face |

| Pressure Testing | Rated for drilling vibration/stress | Rated for static isolation |

| Cost | Premium (Specialized Engineering) | Economical |

Conclusion: Don’t Compromise on Safety

While a standard gate valve is excellent for isolation, it is not an engineered solution for live tapping. Using a dedicated tapping valve ensures that your cutting machine operates smoothly, your seals remain intact, and your new connection stays leak-free for decades.

At TOT Valve, we provide high-performance Mueller-compatible tapping valves and heavy-duty WCB tapping sleeves designed for the most demanding municipal and industrial environments.