Selecting the right butterfly valve sizes is critical for ensuring a leak-proof fit within your piping system. Whether you are designing a new installation or replacing an existing valve, understanding the precise dimensions of a butterfly valve—including face-to-face length and flange compatibility—is non-negotiable.

In this guide, we provide a comprehensive butterfly valve size chart based on international standards like API 609 and ASME B16.1.

Table of Contents

Toggle1. Understanding Butterfly Valve Types and Sizes

Before looking at the numbers, it is important to note that butterfly valve dimensions change depending on the body type.

Wafer Type: The slimmest design, fitting between two pipe flanges.

Lug Type: Features threaded inserts (lugs) for dead-end service.

Double Flanged: Typically used for larger diameters, featuring integrated flanges.

2. Universal Butterfly Valve Size Chart (2” to 12”)

Below is a standard reference for butterfly valve dimensions for Class 150 (PN16) ratings. These measurements are essential for calculating the “face-to-face” (L) and “total height” (H) in your CAD drawings.

| Nominal Size (Inch) | DN (mm) | Face-to-Face (L) | Top Height (H1) | Bottom Height (H2) |

| 2″ | 50 mm | 1.69″ (43 mm) | 6.34″ (161 mm) | 3.15″ (80 mm) |

| 3″ | 80 mm | 1.81″ (46 mm) | 7.13″ (181 mm) | 3.74″ (95 mm) |

| 4″ | 100 mm | 2.05″ (52 mm) | 7.87″ (200 mm) | 4.49″ (114 mm) |

| 6″ | 150 mm | 2.20″ (56 mm) | 8.90″ (226 mm) | 5.47″ (139 mm) |

| 8″ | 200 mm | 2.36″ (60 mm) | 10.24″ (260 mm) | 6.89″ (175 mm) |

| 10″ | 250 mm | 2.68″ (68 mm) | 11.50″ (292 mm) | 7.99″ (203 mm) |

| 12″ | 300 mm | 3.07″ (78 mm) | 13.27″ (337 mm) | 9.53″ (242 mm) |

Note: Dimensions may vary slightly by manufacturer and pressure rating (e.g., Class 300 vs. Class 150).

3. Deep Dive: 6″ Butterfly Valve Dimensions

The 6″ butterfly valve dimensions (DN150) are among the most searched in the industry. For a standard 6-inch wafer-style valve:

Face-to-Face: Approximately 2.20 inches (56 mm). This is the narrow space the valve occupies between flanges.

Stem Connection: Often follows ISO 5211 F07 or F10 patterns for actuator mounting.

Weight: Typically weighs between 18–25 lbs (8–11 kg) depending on the material (e.g., Ductile Iron vs. SS316).

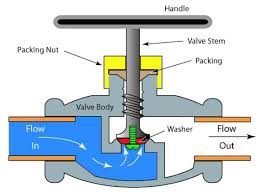

4. How to Measure a Butterfly Valve

If you are replacing an old valve and don’t have the data sheet, follow these steps to confirm your butterfly valve dimension:

Face-to-Face (L): Measure the distance from one seating surface to the other.

Inside Diameter (ID): Measure the bore of the valve when the disc is fully open.

Flange Bolt Circle: Count the number of bolt holes and measure the distance between opposite holes to confirm if it is ANSI, DIN, or JIS standard.

5. Space Comparison: Butterfly Valve vs. Ball Valve Dimensions

Many engineers search for ball valve size charts when considering alternatives. In general:

Space Saving: A 6″ butterfly valve is significantly shorter (Face-to-Face) than a 6″ ball valve dimension chart would show. A ball valve’s length can be 3 to 4 times greater than a butterfly valve’s.

Weight: Butterfly valves are much lighter, reducing the need for heavy pipe supports.

Conclusion

Accurate butterfly valve sizes are the foundation of a safe and efficient piping layout. By using this butterfly valve size chart, you can ensure that your system maintains high flow rates without installation conflicts.