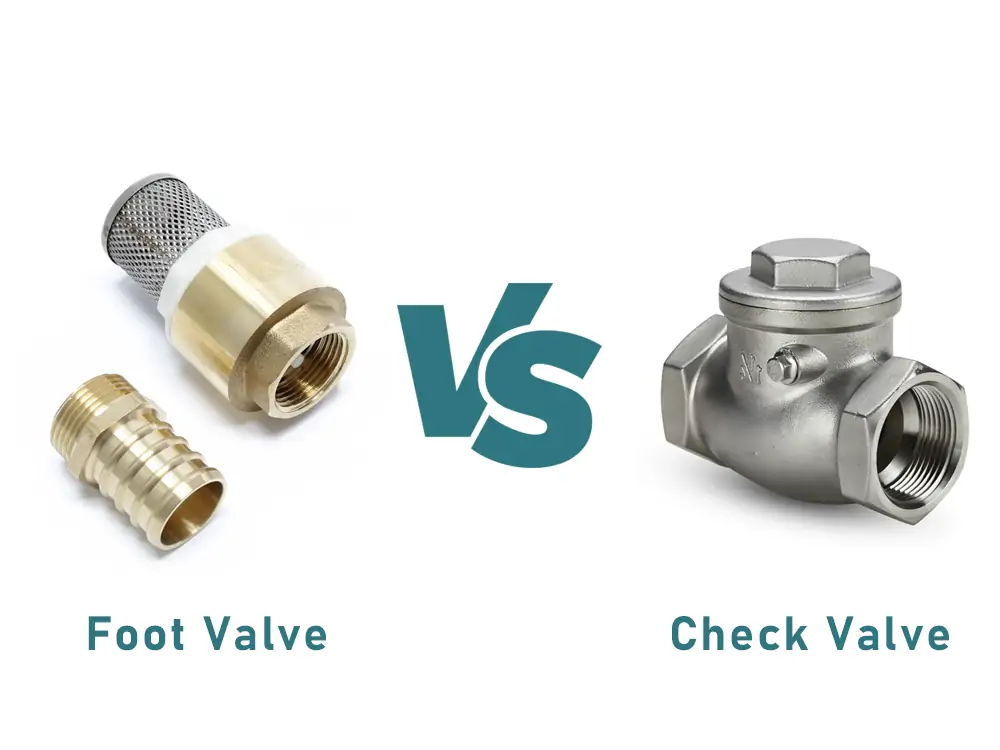

In any fluid handling system, preventing backflow is essential to protect equipment and maintain efficiency. While searching for solutions, you will inevitably encounter two similar components: the Check Valve and the Foot Valve.

At first glance, they perform the same function—allowing flow in one direction and blocking it in the other. However, in the world of engineering, their placement, design, and specific roles are vastly different. This guide will clarify the difference between a check valve and a foot valve so you can make the right choice for your system.

Table of Contents

Toggle1. The Fundamental Distinction

The simplest way to understand the relationship is this: Every foot valve is a type of check valve, but not every check valve can function as a foot valve.

Check Valve: A general-purpose valve installed anywhere in a pipeline to prevent fluid from flowing backward.

Foot Valve: A specialized check valve installed specifically at the intake end (bottom) of a pump suction line.

2. Comparison Table: Check Valve vs. Foot Valve

Google prioritizes structured data. This table is designed to help your page rank for “Comparison” searches.

| Feature | Check Valve | Foot Valve |

| Primary Location | Anywhere in the system (Horizontal/Vertical) | Bottom of the suction pipe (Inlet) |

| Inlet Protection | None (Usually open port) | Includes a Strainer/Screen |

| Core Purpose | Protects pumps from water hammer | Prevents pump from losing prime |

| Flow Direction | Inline (In-and-out) | Upward (From source to pump) |

| Working Environment | Dry or Submerged | Always Submerged |

3. How a Foot Valve Works (The “Sucking” Logic)

If you are wondering how a foot valve works, imagine it as the gatekeeper of a straw. When a centrifugal pump stops, gravity wants to pull the water back down into the well or tank.

If the water leaves the pipe, the pump “loses its prime” and cannot restart without being manually refilled. The foot valve stays closed under the weight of the water column, keeping the suction pipe full and ready for the next start-up. The integrated strainer is equally important—it prevents debris from entering the pump and causing internal damage.

4. Can a Check Valve Replace a Foot Valve?

This is a common question for DIYers and junior engineers. The short answer is: No.

While you could technically install a standard spring-loaded check valve at the bottom of a pipe, it lacks the strainer required to filter out silt, leaves, and stones. Furthermore, foot valves are engineered with a lower “cracking pressure” (the pressure needed to open the valve), ensuring the pump doesn’t have to work too hard just to lift the water.

5. When to Use Which?

Choose a Check Valve if: You need to prevent backflow into a tank, protect a water meter, or stop “water hammer” shocks in a high-pressure industrial line.

Choose a Foot Valve if: You are drawing water from a lake, well, or river. It is an absolute necessity for any suction-lift application where the pump is located above the water source.

Conclusion: Designing for Reliability

Choosing between a foot valve vs. check valve depends entirely on the layout of your system. A foot valve is your first line of defense at the source, while a check valve is your security guard within the pipeline.

At TOT Valve, we provide high-durability WCB Check Valves for industrial use and specialized Foot Valves with Stainless Steel Strainers for municipal water works.