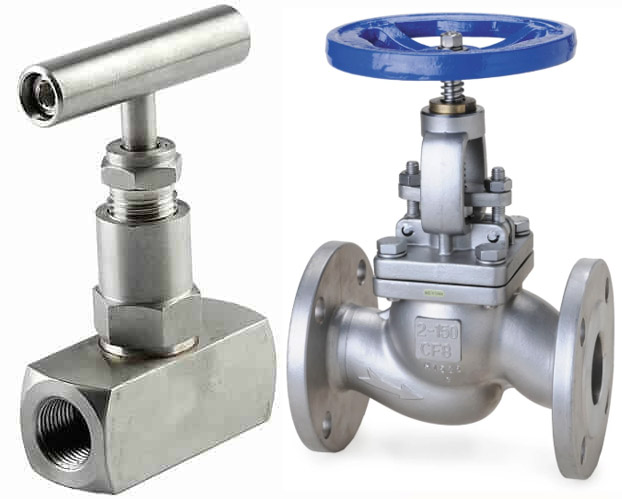

At first glance, the needle valve and the globe valve appear to be members of the same family—and they are. Both are part of the “linear motion” valve group, where a stem moves a plug up and down to regulate flow.

However, in practical engineering, choosing between a needle valve vs globe valve is a choice between surgical precision and bulk volume. Using the wrong one can lead to inaccurate readings, damaged gauges, or inefficient flow regulation. This guide breaks down the critical differences to help you specify the right valve for your application.

Table of Contents

Toggle1. Structural Comparison: The Tip of the Matter

The most defining difference lies in the design of the valve’s “plug” or “disc.”

Globe Valve: Features a relatively large, blunt, or plug-shaped disc. When the valve opens, it allows a significant volume of fluid to pass through a large orifice almost immediately.

Needle Valve: As the name suggests, it features a long, tapered, needle-like point on the end of the valve stem. This “needle” fits into a tiny seat, allowing for incredibly fine adjustments.

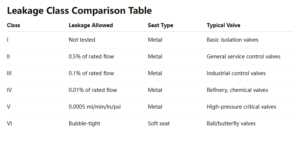

2. Needle Valve vs. Globe Valve: The Comparison Table

For quick reference, here is how these two throttling valves compare across key technical metrics:

| Feature | Globe Valve | Needle Valve |

| Orifice Size | Large (Full pipe diameter) | Tiny (Pin-sized) |

| Flow Control | General Throttling | Precision Metering |

| Typical Sizes | 2″ up to 24″+ | 1/8″ to 1″ (Standard) |

| Pressure Drop | Moderate to High | Very High |

| Adjustment | Few turns for full open | Many turns for micro-adjustments |

| Main Use | High-volume flow regulation | Instrument protection & Sampling |

3. When to Choose a Needle Valve?

You should specify a needle valve when your primary goal is precision and protection rather than moving large amounts of liquid.

Pressure Gauge Protection: Needle valves are often used as “snubbers” before a pressure gauge to prevent sudden pressure surges from damaging the instrument.

Chemical Injection: When you need to dose a system with a very specific, tiny amount of chemical (e.g., drops per minute).

Calibration Labs: For fine-tuning gas flow in analytical instruments.

4. When to Choose a Globe Valve?

The globe valve is the workhorse of industrial throttling. Choose it when you need to handle significant volume while still maintaining control.

Steam and Cooling Systems: Where you need to regulate the temperature by adjusting the volume of steam or water.

General Industrial Processing: When the pipe size is $2”$ or larger, a needle valve is physically impossible to use; the globe valve takes over.

Frequent Operation: Globe valves are robust and designed for repetitive opening and closing in high-flow environments.

5. Can a Globe Valve Replace a Needle Valve?

The short answer is: No. A standard globe valve lacks the “resolution” required for precision work. Because the disc is wide, even a tiny turn of the handle results in a large change in flow. Conversely, a needle valve cannot replace a globe valve because its tiny orifice would create a massive bottleneck (pressure drop), making it impossible to transport high volumes of fluid.

Conclusion: Resolution vs. Capacity

In the debate of needle valve vs. globe valve, the decision comes down to the scale of your flow. If you need to move a river, use a globe valve. If you need to measure a drop, use a needle valve.

At TOT Valve, we provide high-pressure Stainless Steel Needle Valves for instrumentation and heavy-duty Forged Steel Globe Valves for industrial steam and oil service.