The rapid expansion of the hydrogen economy is centered around two critical infrastructures: Hydrogen Refueling Stations (HRS) and Hydrogen Fuel Cell Vehicles (FCEV). While one requires heavy-duty high-pressure storage, the other demands ultra-lightweight precision.

In both cases, the integrity of the hydrogen fittings, valves, and tubing is what determines the safety and efficiency of the entire system. This article explores the specialized valve requirements for the 35MPa and 70MPa hydrogen ecosystems.

Table of Contents

Toggle1. Fuel Cell Systems: The Need for Precision and Lightness

A fuel cell valve operates under different constraints than an industrial plant valve. In an FCEV (Fuel Cell Electric Vehicle) power stack, space and weight are at a premium.

Compact Design: Our hydrogen solenoid valves for fuel cells are engineered with lightweight aluminum or 316L alloy bodies to reduce the overall weight of the vehicle’s power plant.

Rapid Response: Fuel cell stacks require precise hydrogen dosing. Our solenoid valves offer millisecond response times to ensure optimal stoichiometric ratios during varying load conditions.

Durability: Designed for high-cycle life, these valves can handle the frequent start-stop cycles inherent in automotive transportation.

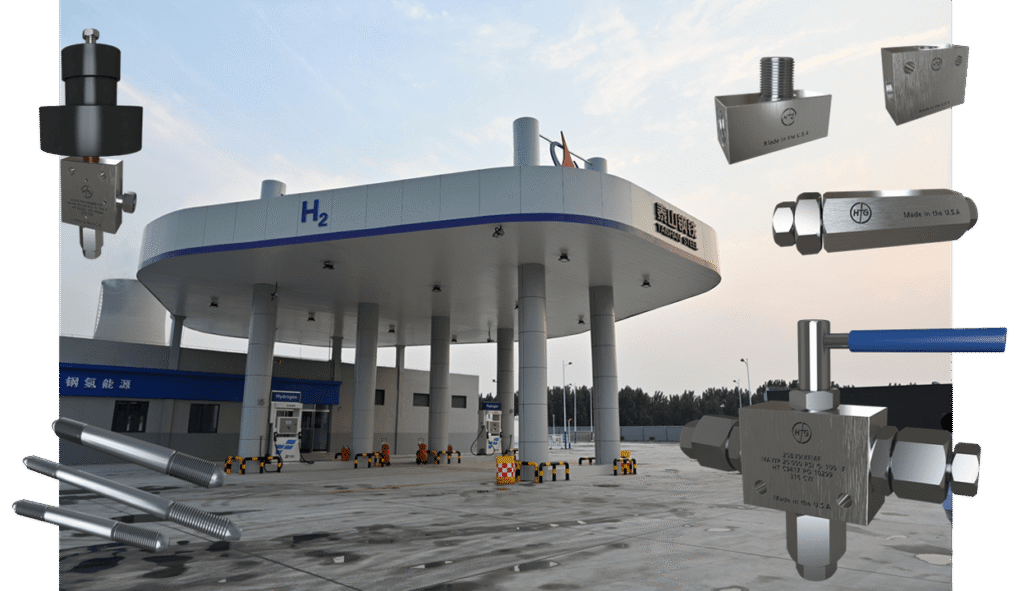

2. Refueling Infrastructure: Mastering 35MPa and 70MPa Challenges

Hydrogen refueling station valves must withstand some of the most punishing conditions in the gas industry. Hydrogen is typically stored and dispensed at pressures of 350 bar (35MPa) or 700 bar (70MPa).

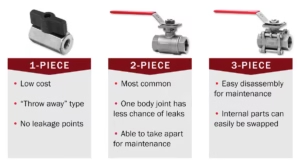

High-Pressure Storage: For bulk storage arrays, our hydrogen ball valves and globe valves are rated for pressures up to 15,000 PSI, ensuring a bubble-tight seal even under extreme mechanical stress.

Thermal Management: During rapid refueling, hydrogen temperatures can drop significantly (Joule-Thomson effect). Our valves are tested to maintain seal elasticity at temperatures as low as -40°C.

Safety & Relief: Every HRS requires high-precision hydrogen pressure relief valves to prevent over-pressurization during the compression and dispensing stages.

3. Ensuring System Integrity: Hydrogen Tubing and Fittings

A valve is only as good as the connection points around it. To eliminate leak paths in a high-pressure hydrogen environment, the hydrogen fittings and hydrogen tubing must be perfectly matched to the valve ports.

Tube Compatibility: We recommend high-quality, fully annealed 316L stainless steel hydrogen tubing. Our fittings utilize a double-ferrule design to provide a gas-tight, vibration-resistant grip that exceeds the requirements of high-pressure hydrogen service.

Avoid Galling: In 70MPa systems, thread galling is a major risk. Our hydrogen fittings feature specialized surface treatments to ensure they can be assembled and disassembled without compromising the threads or the seal.

Material Consistency: By using our integrated range of valves, fittings, and tubing, you ensure a uniform coefficient of thermal expansion across the entire system, preventing leaks caused by temperature-induced contraction.

4. Why Total System Compatibility Matters

Using a mix-and-match approach with different suppliers for valves and hydrogen fittings can lead to “interface failures.” In the hydrogen world, small misalignments lead to large leaks.

We offer a complete Hydrogen Transfer Kit that includes:

High-Pressure Valves (Ball, Check, and Needle).

Precision Hydrogen Fittings (Double ferrule and Threaded).

ASTM Standard Tubing (Calibrated for hydrogen service).

Conclusion

Whether you are scaling up a 70MPa refueling network or refining a hydrogen fuel cell stack, your choice of fluid control components is the most critical safety decision you will make. Our engineered solutions are designed to bridge the gap between high-pressure challenges and high-performance results.