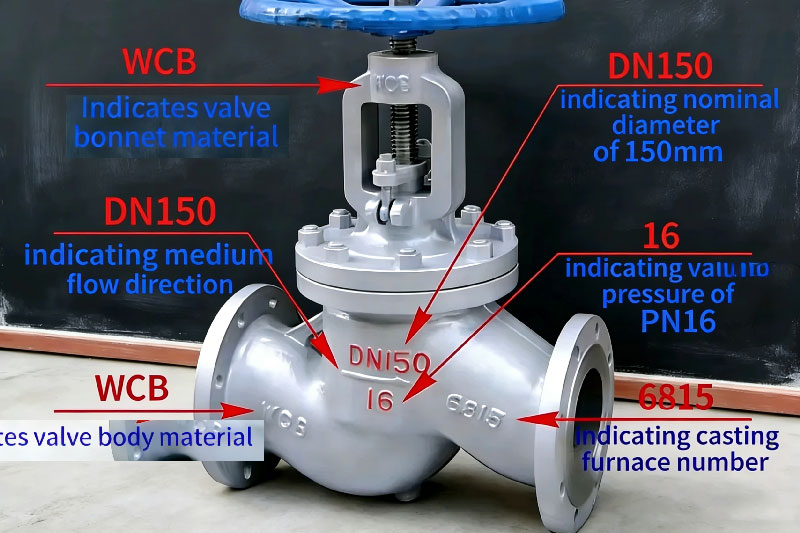

Industrial valve markings may look like a chaotic jumble of alphanumeric codes, but they are actually a valve’s “Technical ID Card.” Symbols like DN, PN, WCB, and CF8 hold the keys to the valve’s size, pressure rating, and material composition.

If you’ve ever felt overwhelmed by these markings, this guide will help you decode the “secret language” of valves to ensure safe and accurate selection for your piping systems.

Table of Contents

Toggle1. Dimensional and Pressure Specifications

These markings determine if a valve will physically fit into your piping system and whether it can handle the operating stress.

A. Nominal Diameter (DN / NPS)

DN (Diameter Nominal) is the metric designation (mm) for valve size, while NPS (Nominal Pipe Size) is the imperial equivalent (inches).

Example: DN100 indicates a 100mm nominal bore.

Note: This is the nominal size used for matching pipes, not necessarily the exact internal bore diameter.

B. Nominal Pressure (PN / Class)

PN indicates the pressure rating in Bars (at reference temperature). Class is the American standard used in ASME systems.

Example: PN16 means the valve is rated for 16 Bar (approx. 1.6 MPa or 232 PSI).

Example: Class 150 is the standard entry-level pressure rating for ASME-compliant valves.

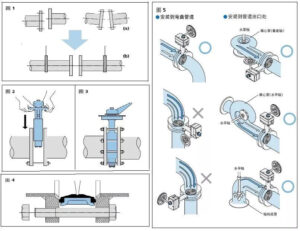

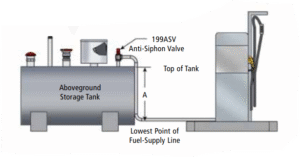

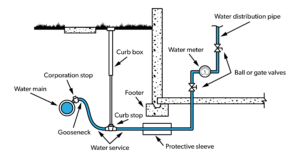

C. Flow Direction Arrow

The arrow cast or etched onto the valve body is critical for installation.

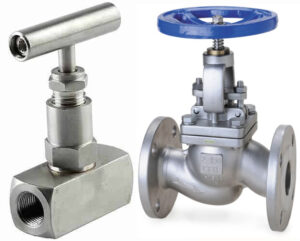

Uni-directional: Valves like Globe, Check, and Needle valves must be installed with the arrow pointing in the direction of the medium flow.

Bi-directional: Valves like Gate and Ball valves often have no arrow, meaning they can be installed in either direction.

2. Material Performance Identifiers

Material markings tell you what the valve is made of, which determines its chemical compatibility and temperature limits.

A. Body Material (WCB, CF8, QT)

WCB: Cast Carbon Steel. The “workhorse” material for water, oil, and steam in non-corrosive environments.

CF8 / CF8M: Stainless Steel 304 and 316 respectively. These are the gold standard for corrosive chemical and food-grade applications.

QT450: Ductile Iron. High-strength iron used for lower-pressure water and gas lines where cost-effectiveness is key.

CF3M: Ultra-low carbon 316L Stainless Steel, superior for resisting intergranular corrosion.

B. Trim and Seat Materials (EPDM, PTFE, Stellite)

The “Trim” refers to the internal moving parts (disc, seat, stem).

EPDM: A synthetic rubber used for resilient seated butterfly valves. Excellent for water and weather resistance ( -50°C to 150°C).

PTFE (Teflon): Famous for its extreme chemical resistance.

Stellite: A hard-facing cobalt alloy used on metal seats to prevent wear in high-pressure steam or abrasive slurries.

3. Standards and Certifications

These marks prove that the valve was manufactured under strict quality controls.

API 6D: The American Petroleum Institute standard for pipeline valves (Oil & Gas).

CE: Indicates compliance with European health, safety, and environmental protection standards.

ISO 9001: Proof of a standardized quality management system during manufacturing.

Traceability Code (Heat Number): A unique serial number (e.g., JM608) used to trace the valve back to its original raw material batch and test report.

4. Flow Path Characteristics

FB (Full Bore): The internal diameter of the valve is equal to the pipe’s diameter. This results in minimal pressure drop and is ideal for “pigging” pipelines.

RB (Reduced Bore): The internal flow path is smaller than the pipe diameter. These valves are more compact and cost-effective but create higher flow resistance.

Summary Checklist for Valve Identification

When inspecting a valve, always verify these four pillars:

Size & Pressure: Does the DN/PN match your pipe and pump capacity?

Material: Is the WCB or Stainless Steel appropriate for your medium (acidic vs. neutral)?

Direction: Is the arrow pointing downstream?

Certification: Does it have the API or CE mark required for your project?

Precision in reading these markings is the first step toward a leak-free and safe industrial operation.