In the vast networks of municipal water, industrial piping, and HVAC systems, blue is the dominant color for valves. This choice is far from a random aesthetic preference; it is the result of a strategic convergence between corrosion science, safety regulations, and manufacturing economics.

Understanding why blue has become the industry “default” reveals much about the performance and longevity expectations of modern fluid control systems.

Table of Contents

Toggle1. The First Line of Defense: Anti-Corrosion

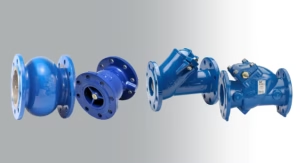

The primary reason valves are painted is protection. Most industrial valves are made from Ductile Iron (DI) or Cast Steel, materials that are highly susceptible to electrochemical corrosion when exposed to moisture, soil, or salt.

Physical Barrier & Chemical Passivation

Blue coatings are typically made of Fusion Bonded Epoxy (FBE) or Alkyd Resin. These coatings act as a “plastic shield,” isolating the metal from oxygen and water.

Longevity: An uncoated ductile iron valve may fail within 3–5 years due to graphitization; a blue epoxy-coated valve can last over 15 years.

Sacrificial Protection: Many blue industrial paints contain zinc-rich pigments. These act as a sacrificial anode, oxidizing before the valve body does, which increases corrosion resistance by 30-50% compared to standard grey paints.

2. Safety Logic: The Global Language of Media Coding

In complex industrial environments, color acts as a “visual shorthand” to prevent operational errors. International standards, such as ASME A13.1 and ISO 14726, provide guidelines for color-coding pipes and valves.

Visual Recognition per Media Type

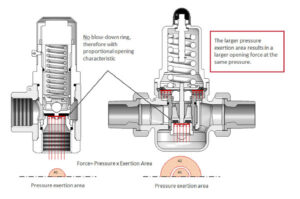

Potable Water: Blue is the universal identifier for drinking water and cooling water. In municipal systems, blue valves distinguish “Potable Water” from “Recycled/Grey Water” (often purple or grey), preventing cross-contamination.

Compressed Air: In manufacturing plants, blue is frequently used for compressed air and nitrogen lines. The bright blue hue warns operators of high-pressure risks, offering higher visibility than grey or black.

Low-Temperature Systems: Blue is psychologically associated with “Cold.” It is often used for chilled water or glycol lines, contrasting sharply with the red used for fire protection or steam lines.

3. The Science of Pigment: Why Blue?

Why not Green or Red? The answer lies in the chemical stability of the pigment.

Stability of Phthalocyanine Blue: The most common blue pigment (Phthalocyanine) is incredibly stable. It is insoluble in water, oils, and most acids. Unlike red pigments (which fade under UV light) or yellow pigments (which can decompose in acidic environments), blue maintains its integrity and color for decades.

UV Resistance: Blue coatings are typically formulated with UV absorbers. Even after 5 years of direct sunlight exposure, high-quality blue epoxy maintains over 80% of its film integrity, whereas black coatings often suffer from “chalking” (cracking and peeling).

4. Manufacturing & Quality Control Economics

From a production standpoint, the “Blue Standard” offers significant cost-to-performance advantages.

Lower Raw Material Cost: Phthalocyanine Blue is mass-produced globally. It is significantly cheaper than high-performance green (Chromium Oxide) or red (Cadmium) pigments. For a factory producing 100,000 valves a year, choosing blue can save millions in raw material costs.

Ease of Inspection: Defects such as pinholes, scratches, or “holidays” in the coating are much easier to detect by the naked eye against a blue background. This improves the pass rate during Quality Assurance (QA) and reduces the risk of sub-standard products reaching the customer.

Conclusion: The “Sweet Spot” of Reliability

Blue has become the “Gold Standard” for valves because it represents the perfect balance: it offers superior corrosion protection, satisfies international safety standards, and remains cost-effective for mass production.

When you see a blue valve, you aren’t just looking at a color—you are looking at an engineered system designed for 20 years of reliable service.