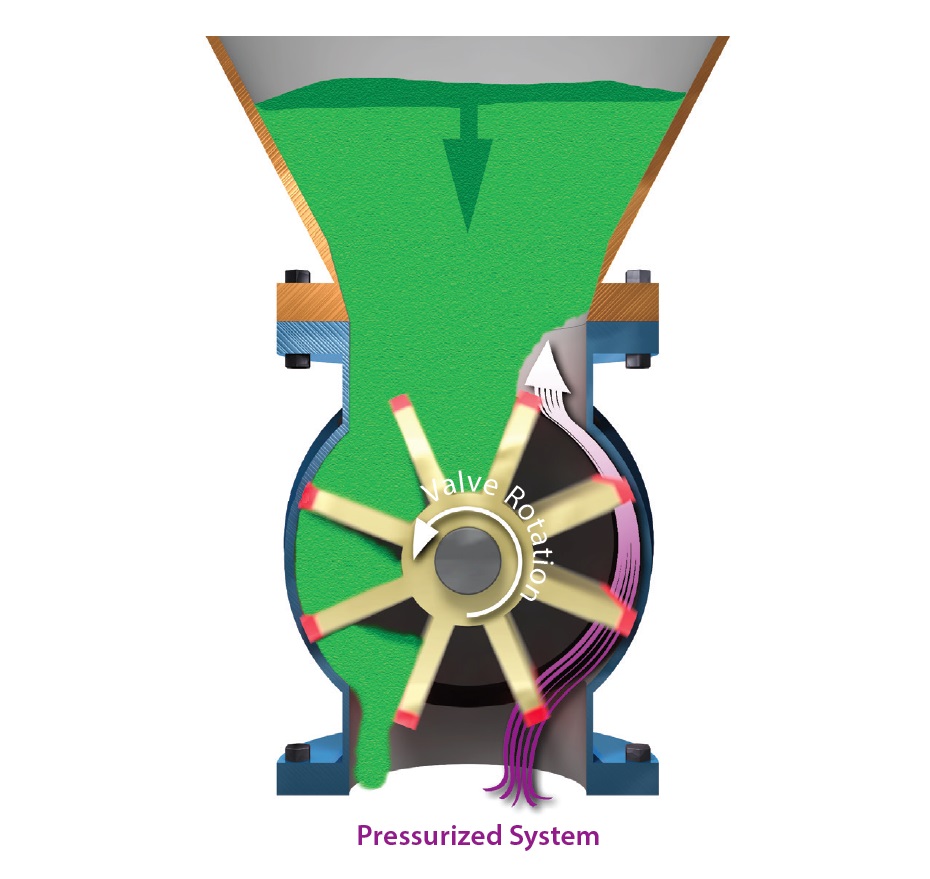

In any industrial dust collection or pneumatic conveying system, the rotary airlock valve is the “unsung hero.” Its job is deceptively simple but technically demanding: it must allow a continuous flow of dust or bulk solids to exit a hopper while simultaneously acting as a high-pressure seal to prevent air from leaking back into the system.

Without a precision-engineered airlock rotary valve, your dust collector will lose suction, your energy costs will spike, and your filters will clog prematurely. In this guide, we explore the critical role of these valves and how to select the right one for your application.

Table of Contents

Toggle1. The Core Function: More Than Just a Feeder

While a standard rotary feeder is designed to meter material flow, a rotary airlock valve is specifically designed to maintain a pressure differential.

In a dust collector, the interior is often under negative pressure (vacuum). If the bottom of the hopper were left open to the atmosphere, air would rush in, swirling the dust back up into the filters. The rotary airlock uses precision-machined vane clearances (typically 0.003″ to 0.005″) to “lock” the air in place while gravity pulls the dust through the rotating pockets.

2. Identifying the Right Valve for Your Dust Type

Not all dust is created equal. When selecting a dust collector rotary airlock, you must match the valve construction to your material:

Abrasive Materials (Sawdust, Sand, Cement): Require Hardened Steel or Ni-Hard liners to prevent the tips of the vanes from wearing down, which would widen the clearance and cause air leaks.

Corrosive Materials (Chemicals, Fertilizers): Require 304 or 316 Stainless Steel bodies and rotors.

Sticky Materials (Food Powders, Resins): Require Teflon-coated internals or “Quick-Clean” designs to prevent material buildup in the rotor pockets.

3. Key Specifications for Peak Efficiency

When reviewing a rotary airlock valve working principle, pay attention to these three technical factors:

A. Vane Design

Fixed Vanes: Best for standard dust and non-abrasive powders.

Adjustable/Replaceable Tips: Ideal for abrasive environments. You can replace the tips (made of rubber, polyurethane, or bronze) without replacing the entire rotor.

B. Displacement (Cubic Feet per Revolution)

You must ensure the valve can handle the volume of dust your system generates. A valve running at 15-20 RPM is ideal; running a valve too fast can cause “turbulence” in the pockets, reducing sealing efficiency.

C. Pressure Differential

Most standard rotary air valves are rated for up to 15 PSI. If your pneumatic system operates at higher pressures, you will need a heavy-duty “High-Pressure” airlock.

4. Symptoms of a Bad Airlock Valve

If you notice the following, your dust collector air lock may be failing:

Visible Dust in the Workplace: Suction at the pickup points has dropped.

Material Bridging: Dust is backing up into the hopper because the valve has seized.

Hissing Sound: Air is whistling past worn vane tips (a clear sign of a lost seal).

5. Engineering Standard: The Rotary Valve Symbol

For engineers designing a new system, the rotary valve symbol on a P&ID (Piping and Instrumentation Diagram) typically resembles a circle with an “X” or a star-shaped rotor inside. Ensuring your valve meets NFPA standards (especially for combustible dust like wood or grain) is critical for plant safety and insurance compliance.