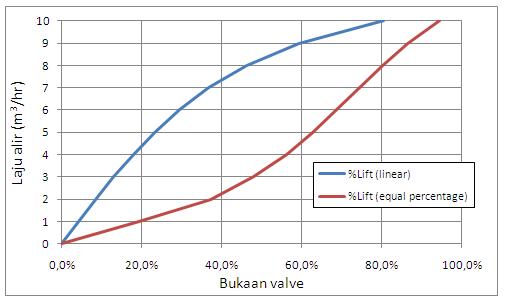

In process automation, choosing a valve isn’t just about pipe size and pressure ratings; it’s about Flow Characteristics. The relationship between the “percentage of valve opening” and the “percentage of full flow” determines how stable your control loop will be.

If you choose the wrong characteristic, your system will either hunt (oscillate) or respond too slowly to changes. In this guide, we dive into the two most critical curves: Linear and Equal Percentage.

Table of Contents

Toggle1. What are Valve Flow Characteristics?

Flow characteristic refers to the relationship between the valve stem travel and the flow rate through the valve. As the linear actuator moves the valve plug, the shape of the plug determines how the flow increases.

There are two main types of characteristics:

Inherent Characteristic: The theoretical curve published by the manufacturer (tested with a constant pressure drop).

Installed Characteristic: The actual performance of the valve once it is installed in a piping system with varying pressures.

2. Linear Flow Characteristics

In a linear control valve, the flow rate is directly proportional to the valve travel.

The Equation:

Where $Q$ is the flow, $L$ is the valve travel (lift), and $k$ is a constant.

Example: If the valve is 50% open, you get 50% of the maximum flow.

Best Use Cases:

Systems where the pressure drop across the valve remains relatively constant.

Liquid level control and flow control in systems with low pipe friction losses.

3. Equal Percentage Flow Characteristics

The equal percentage valve is the most common type of control valve used in the process industry. For equal increments of valve travel, the flow changes by an equal percentage of the existing flow.

The Equation:

The Result: At small openings, the flow changes slowly. As the valve opens wider, the flow increases rapidly.

Example: If a 10% increase in travel changes the flow from 10 to 11 GPM (a 10% increase), the next 10% increase in travel will change the flow from 11 to 12.1 GPM (another 10% increase).

Best Use Cases:

Systems where the pressure drop across the valve decreases as the flow increases (common in long pipelines).

Temperature control loops where the heat exchanger performance is non-linear.

Applications where highly sensitive control is needed at low flow rates.

4. Comparing the Curves: Which One to Choose?

| Feature | Linear Characteristic | Equal Percentage Characteristic |

| Flow Increase | Constant/Steady | Accelerated/Exponential |

| Control Sensitivity | Uniform at all openings | High sensitivity at large openings |

| Pressure Drop Profile | Constant ΔP | Varying ΔP (High to Low) |

| Typical Actuator | Electric Linear Actuator | Linear or Rotary Actuator |

5. The Role of the Linear Actuator

Whether you use a linear or equal percentage plug, the precision of your electric linear actuator is paramount. A high-quality linear actuator motor ensures that the valve stems move in micro-increments, allowing the valve curves to be followed accurately.

Without a motorized linear actuator capable of high-resolution positioning, the theoretical “Equal Percentage” benefit is lost to “stiction” or dead-band errors.

6. Installed Characteristics: The Reality Check

It is a common engineering “rule of thumb” that many systems with a linear characteristic on paper actually behave like an equal percentage valve once installed, and vice versa. This is due to the pump curves and pipe friction.

As a rotary and linear valve supplier, we recommend performing a system-wide hydraulic analysis before selecting your final valve trim.