In industrial refrigeration—ranging from massive cold storage facilities to chemical processing plants—valves are the primary guardians of system efficiency and safety. Unlike commercial HVAC systems, industrial applications involve extreme temperature gradients, high pressures, and often hazardous refrigerants like Ammonia (R717) or CO2 (R744).

Selecting the right industrial shut-off valves and expansion valves is not merely a matter of pipe size; it requires a deep understanding of fluid dynamics, material science, and thermodynamic control.

Table of Contents

Toggle1. Industrial Shut-Off Valves: Ensuring Absolute Isolation

In a large-scale refrigeration rack, the ability to isolate components for maintenance without refrigerant loss is critical. Industrial-grade shut-off valves (also known as stop valves) must offer more than just a basic seal.

The Importance of Back-Seating

High-quality industrial valves feature a back-seating design. This allows the valve to be repacked while under pressure by sealing the stem against the bonnet when fully open. This feature is vital for reducing downtime in 24/7 industrial operations.

Material Integrity

For ammonia systems, brass and bronze are strictly prohibited due to corrosion risks. Industrial valves must utilize:

Low-temperature Cast Steel or Stainless Steel: To prevent brittle fracture at temperatures reaching -50°C.

Teflon (PTFE) Sealing: To ensure a bubble-tight seal that remains flexible even in cryogenic conditions.

2. Expansion Valves: Precision Metering at Scale

The expansion valve is the “brain” of the refrigeration cycle, regulating the flow of liquid refrigerant into the evaporator. In industrial settings, where loads fluctuate significantly, precision is paramount.

Thermostatic vs. Electronic Expansion Valves (EEV)

While Thermostatic Expansion Valves (TXVs) remain popular for their reliability and lack of power requirements, Electronic Expansion Valves (EEVs) are becoming the standard for large-scale industrial systems.

TXV Selection: Ideal for stable loads; relies on a sensing bulb to manage superheat.

EEV Selection: Best for variable loads; utilizes a motorized needle to provide rapid, pinpoint accuracy, often resulting in 15–20% energy savings in large cold stores.

Capacity and MOP (Maximum Operating Pressure)

When selecting an expansion valve from a selection chart, engineers must consider the MOP to protect the compressor from overloading during start-up or defrost cycles. An undersized valve will starve the evaporator, while an oversized valve will cause “hunting,” leading to unstable temperatures and potential liquid slugging.

3. The Role of Solenoid Operated Valves (SOV)

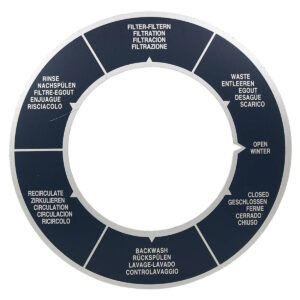

In industrial automation, the solenoid valve (or SOV) acts as the primary tool for remote flow control. In refrigeration, they are commonly used in liquid lines, suction lines, and hot gas defrosting lines.

Direct-Acting vs. Pilot-Operated: For large-bore industrial piping, pilot-operated valves are used to handle high flow rates with minimal electrical power.

High MOPD Requirements: Industrial SOVs must be rated for a high Maximum Opening Pressure Differential (MOPD) to ensure the valve can open even when there is a significant pressure gap between the upstream and downstream sides.

4. Maintenance and Safety Standards

Industrial refrigeration valves must comply with rigorous standards such as PED (Pressure Equipment Directive) or ASME. Key maintenance features to look for include:

Extended Bonnets: Essential for insulated pipes to keep the stem packing accessible and prevent ice buildup from interfering with valve operation.

Ease of Service: Designs that allow for the replacement of internal parts (cages, seats, and seals) without removing the valve body from the welded pipeline.

Conclusion: Engineering for Reliability

Selecting valves for industrial refrigeration is an exercise in risk management. Whether you are choosing an isolation valve for a suction line or a metering valve for an ammonia evaporator, the focus must remain on material compatibility and mechanical longevity. High-performance valves do more than control flow; they protect the high-value assets—compressors and products—that drive your business.