In the world of energy infrastructure, long-distance pipelines (LDP) require components that can survive decades of underground service with zero maintenance. The Fully Welded Ball Valve has emerged as the definitive choice for these high-stakes environments. Unlike bolted-body valves, the fully welded structure eliminates potential leak paths, making it the “sentinel” of modern oil and gas transport.

Table of Contents

Toggle1. Core Applications: Where Reliability is Non-Negotiable

Designed to meet rigorous industry standards such as API 6D, API 607 (Fire Safe), and ASME B16.34, these valves are the primary isolation points for:

Energy Transport: Natural gas transmission lines (main and branch), crude oil pipelines, and refinery terminals.

District Heating: Urban heating networks where the valve is often buried directly under streets.

Industrial Plants: Petrochemical, shipbuilding, and power generation where high-pressure integrity is paramount.

2. Technical Specifications Overview

| Parameter | Specification Details |

| Size Range | DN500 – DN1600 (NPS 20″ – 64″) |

| Pressure Class | PN1.6 – 42.0 MPa (Class 150 – 2500LB) |

| Temperature Range | Standard: -29°C to 200°C (Extended: -196°C to 350°C) |

| Body Materials | Carbon Steel (A105, WCB), Stainless Steel (316L), Low Temp Alloy |

| Sealing System | Soft Seat (PTFE, Devlon) or Metal-to-Metal with Tungsten Carbide |

| Operation | Gearbox, Electric, Pneumatic, or Gas-over-Oil Actuators |

| Internal Logic | DBB (Double Block & Bleed), DIB-1, DIB-2 |

3. Engineering Advantages: Built for the “Bury and Forget” Model

(1) Zero Leakage Integrity (The Fully Welded Advantage)

By welding the body and bonnet into a single unit, we eliminate flanges and gaskets. This creates a monolithic structure that is immune to external pipeline stress caused by soil movement, seismic activity, or heavy vehicle traffic in urban areas.

(2) Advanced Safety Systems

Automatic Cavity Pressure Relief: When trapped medium expands due to temperature spikes, the spring-loaded seats automatically retract to bleed excess pressure back into the pipeline.

Fire-Safe Secondary Seal: In the event of a fire, once the primary soft seal is consumed, a secondary metal-to-metal seal is formed to prevent catastrophic leakage (Certified to API 607).

Anti-Static & Blow-out Proof Stem: Ensures electrical continuity and prevents stem ejection under extreme internal pressure.

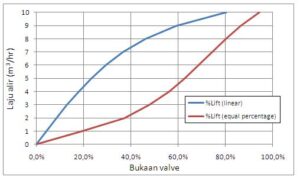

(3) Superior Flow Performance

The Full Bore design ensures the valve’s internal diameter matches the pipeline. This results in a flow coefficient ($C_v$) almost identical to a straight pipe, drastically reducing pumping energy costs and allowing for easy passage of pipeline pigs.

4. Installation & Buried Service Best Practices

Installing a valve that will be buried for 30 years requires precise execution:

Cooling During Welding: During the welding process, the valve cavity should be filled with wet asbestos or cooling water to protect the sensitive internal seals from heat distortion.

Stem Extension for Buried Use: For underground pipelines, we provide customized stem extensions. This keeps the operation mechanism (actuator/gearbox) above ground or in a small access manhole while the valve body remains safely buried.

Emergency Sealant Injection: Many of our large-bore models are equipped with secondary sealant injection ports for both the stem and the seat. This allows operators to inject emergency grease to restore sealing integrity without shutting down the line.

Conclusion: Reducing Total Cost of Ownership (TCO)

While the initial investment in a fully welded large-bore ball valve is higher than standard bolted designs, the Total Cost of Ownership is significantly lower. By eliminating the need for periodic gasket replacements and massive concrete valve pits, these valves provide the most economical and safe solution for critical infrastructure.