In industrial fluid systems, few things are as frustrating as a water shut-off valve stuck in the open position during a critical maintenance window—or worse, a valve stem that keeps spinning without moving the gate. These failures are rarely sudden; they are usually the result of gradual mechanical degradation that could have been prevented.

For asset managers, understanding why gate valves seize is the first step toward reducing unscheduled downtime and extending the lifecycle of your piping infrastructure.

Table of Contents

Toggle1. Root Cause Analysis: Why Do Valves Seize?

If your gate valve keeps spinning or feels “frozen,” one of the following three culprits is usually to blame:

A. Mineral Scaling and “Bridging”

In systems carrying hard water or slurries, calcium, lime, and particulates settle in the bottom “pocket” of the gate valve. Over time, this material hardens, preventing the gate from reaching a full close. When an operator tries to force it, the internal threads strip, leading to a spinning valve stem.

B. Galvanic and Atmospheric Corrosion

For valves left in one position for years, the gate and the seat can literally bond together through corrosion. This is especially common in metal-to-metal seated valves where the protective coatings have worn away.

C. Dried Packing and Friction

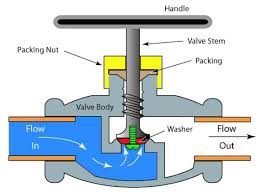

The packing material around the stem requires moisture or lubricant to remain flexible. If the packing dries out, it creates immense friction against the stem. The force required to overcome this friction often leads to sheared pins or stripped stem nuts.

2. Proactive Maintenance: Avoiding the “Stuck Valve” Syndrome

To ensure your valves operate when you need them most, implement these three preventative strategies:

Periodic “Exercise” Cycles: Never leave a valve in a fixed position for more than six months. A “full-travel exercise”—closing and opening the valve completely—breaks up early mineral deposits before they harden.

Stem Lubrication: For rising stem valves, the exposed threads should be cleaned and coated with a high-quality, water-resistant anti-seize lubricant. This reduces the torque required for operation and protects the threads from atmospheric rust.

Packing Adjustment: If you notice a slight weep at the stem, tighten the packing nut slightly. If the packing is old, replace it during scheduled shutdowns rather than waiting for a total failure.

3. Engineering Upgrades: Solving the Problem at the Source

If your facility suffers from chronic valve seizures, the problem may not be your maintenance—it may be the valve design itself. For harsh or high-cycle environments, consider these two upgrades:

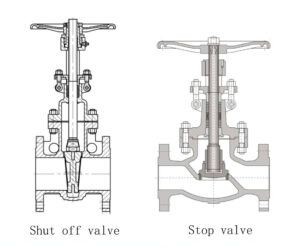

The Non-Rising Stem (NRS) Advantage

In a Non-Rising Stem (NRS) design, the threads are located inside the valve body. This is ideal for tight spaces and protects the critical drive threads from external dust, salt air, and mechanical damage. When combined with a sealed bonnet, the lubrication remains trapped inside, ensuring the valve never “sticks” due to external environmental factors.

The Ceramic Solution for “Zero-Stuck” Operation

Traditional metal valves fail in ash and slag service because the media is harder than the valve. Upgrading to a Ceramic-Lined Knife Gate Valve solves the root cause:

Anti-Scaling: Structural ceramics have an extremely low surface energy; minerals and slurries cannot easily bond to them.

Self-Cleaning: The knife edge of the gate physically clears the path, ensuring no “pocket” exists for debris to collect.

Hardness: With a hardness of HRA 88+, the ceramic seat stays smooth, ensuring the torque required to open the valve remains low for its entire service life.

Conclusion: From Reactive to Proactive

A stuck water valve is a symptom of a larger maintenance or selection issue. By implementing regular exercise cycles and choosing valves with NRS architecture or ceramic internals, you can eliminate the “spinning stem” phenomenon and ensure your plant remains operational and safe.