In fluid dynamics, achieving a reliable seal in media laden with solids—such as sewage, slurry, or grit—is a constant challenge. Traditional mechanical valves often seize or clog under these conditions. Enter the Duckbill Valve: a 100% elastomer, sleeve-type check valve that provides a simple yet ingenious solution to backflow prevention.

Table of Contents

Toggle1. Working Principle: The Power of Passive Elasticity

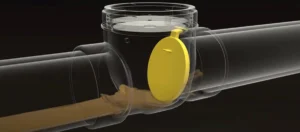

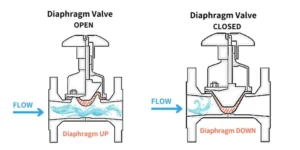

To understand how a duckbill valve works, one must look at its unique “beak” shape. Unlike a diaphragm control valve that requires external actuators, the duckbill valve is entirely passive.

Forward Flow: When upstream pressure exceeds the “cracking pressure” (the natural resilience of the rubber), the lips of the valve peel apart, allowing the medium to pass through.

Backflow Prevention: As soon as the forward flow stops or back-pressure develops, the rubber “lips” collapse back into their molded, flattened shape. The back-pressure itself reinforces the seal, pressing the lips tighter together.

This “one-way” logic relies solely on the elastomeric memory of the rubber, meaning there are no gates to jam, no hinges to rust, and no seats to grind.

2. Duckbill vs. Swing Check Valve: Why Go “Moving-Part-Free”?

When specifying a type of diaphragm valve or check valve, engineers often compare the Duckbill to the traditional Swing Check Valve. Here is why the Duckbill is winning in harsh environments:

| Feature | Swing Check Valve | Duckbill Check Valve |

| Mechanical Parts | Hinges, pins, and discs (prone to rust). | 100% Elastomer (No moving parts). |

| Clogging Risk | High. Solids get trapped in the hinge or seat. | Zero. Solids pass through the flexible beak. |

| Water Hammer | Common. The disc “slams” shut. | Silent. The rubber sleeve absorbs energy. |

| Maintenance | High. Requires regular lubrication/cleaning. | Zero. Self-cleaning by the flow of media. |

| Sealing Surface | Metal-to-metal (prone to scoring). | Flexible rubber (seals around small debris). |

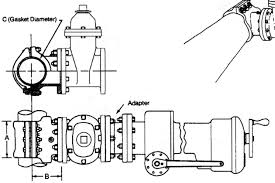

3. Industrial Configurations: Mounting Types

Depending on the piping architecture, there are three primary types of duckbill valves:

Slip-on Type: Slides directly over the end of a discharge pipe and is secured with stainless steel clamps. Ideal for outfall lines.

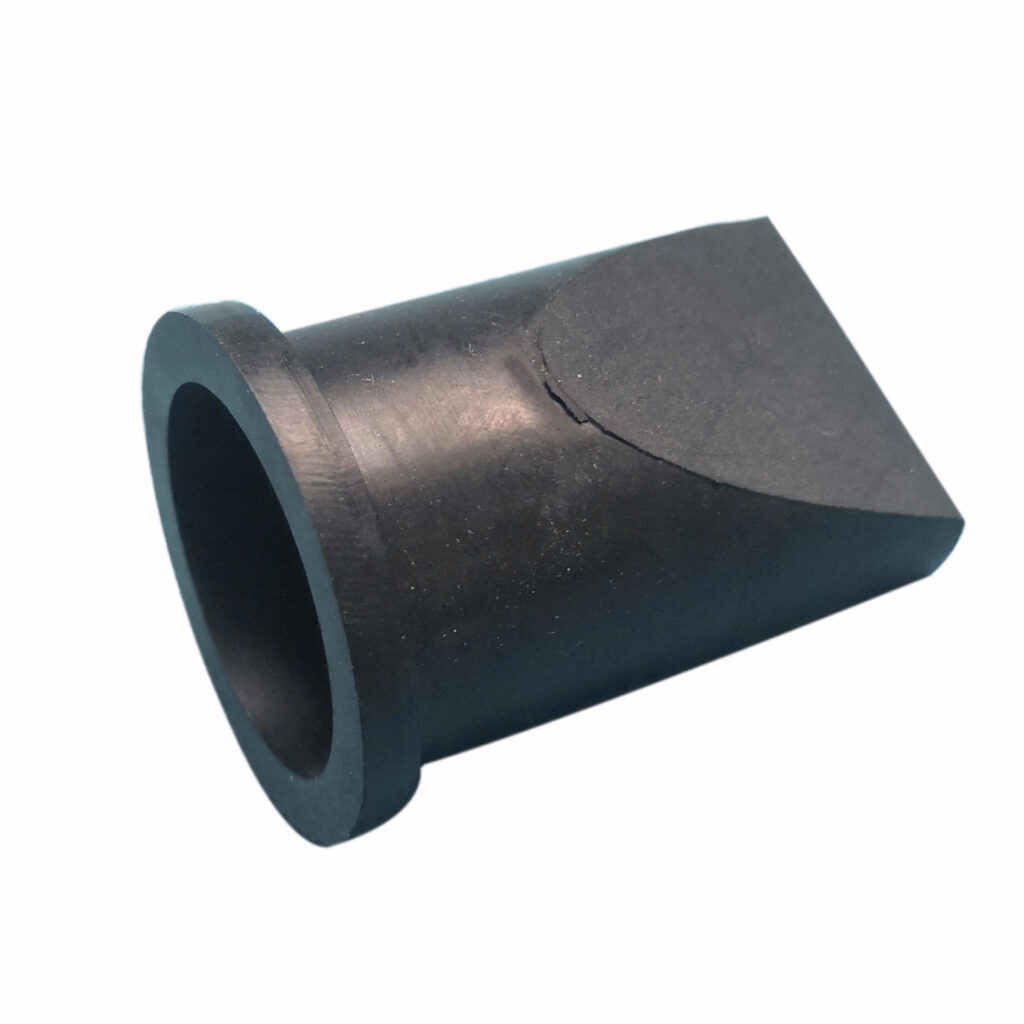

Flanged Type: Built with an integral rubber flange that bolts directly between pipe flanges. Often used as an inline check valve.

Threaded/In-line Type: Housed within a metal or plastic casing for high-pressure industrial applications, functioning similarly to a membrane valve.

4. Material Selection Guide: Chemical and Environmental Compatibility

The performance of a rubber duckbill valve is only as good as the elastomer it is made from. Material selection is the most critical step for engineers:

EPDM (Ethylene Propylene): The industry standard for water treatment. Excellent resistance to weather, ozone, and aging. Best for outdoor municipal outfalls.

Silicone: Highly flexible with a wide temperature range. Used in silicone duckbill valves for food-grade, medical, or low-pressure sensitive applications.

Nitrile (Buna-N): The go-to choice for oil-laden media. Resistant to fats, oils, and greases.

Viton (FKM): Required for aggressive chemical processing or high-temperature corrosive fluids.

5. Applications: From Stormwater to Slurry

Because the duckbill valve can seal around solids, it is the preferred choice for:

Combined Sewer Overflows (CSO): Preventing river water from entering the sewer system during high tides.

Pumping Stations: Protecting pumps from reverse flow in grit-heavy sewage.

Aeration Systems: Preventing sludge from backing up into the air headers of wastewater treatment tanks.

Pulp and Paper: Handling fibrous slurries that would jam a standard diaphragm valve.

Conclusion: Simplifying Fluid Control

The duckbill check valve proves that the most sophisticated solution is often the simplest. By eliminating mechanical failure points, it reduces downtime and maintenance costs significantly. When compared to a swing check valve, the duckbill offers superior performance in “dirty” media, making it an essential component of modern sustainable infrastructure.