While most recognize polyester as the backbone of the global textile industry, its entry into high-precision mechanical engineering—specifically valve manufacturing—has marked a significant shift toward more sustainable and cost-effective fluid control solutions. Known technically as polyethylene terephthalate (PET), this synthetic fiber offers a unique intersection of mechanical toughness, chemical stability, and tribological (friction-reducing) properties that traditional materials often lack.

Table of Contents

Toggle1. What is Polyester Fiber? The Material Profile

Polyester fibers are synthetic polymers formed by the polycondensation of organic dicarboxylic acids and diols. In industrial valve applications, we primarily utilize PET, though high-performance variants like PBT (Polybutylene Terephthalate) are used when superior thermal stability is required.

Core Properties Driving Valve Innovation:

Elastic Recovery: Unlike many natural fibers, polyester maintains its shape under mechanical stress, ensuring that seals do not suffer from permanent deformation (creep).

Low Friction Coefficient: With a dry friction coefficient of approximately 0.2–0.3, it significantly reduces the torque required to operate valve stems.

Chemical Resilience: It remains stable in the presence of most organic solvents, salts, and mild acids/bases.

Thermal Window: Standard PET operates reliably up to 120°C (248°F), while modified versions can withstand constant temperatures of 150°C (302°F).

2. Strategic Applications in Valve Components

The integration of polyester fiber into valves is centered around three engineering goals: Sealing Integrity, Wear Reduction, and Fluid Protection.

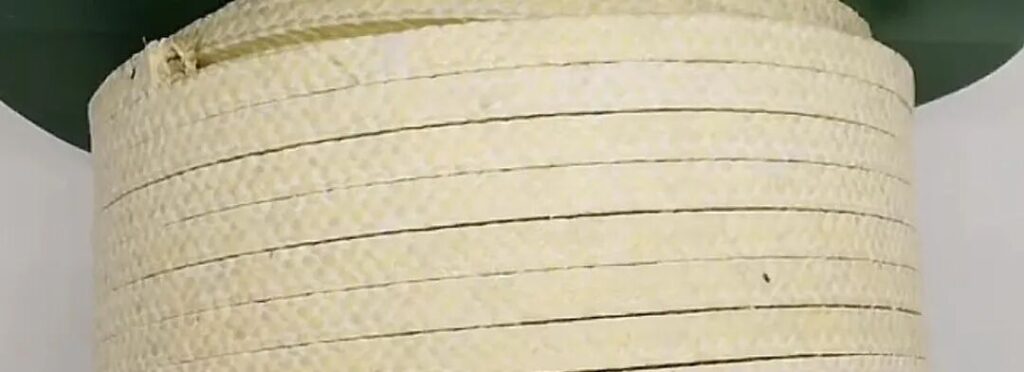

A. Compression Packing and Glands

Valve stem leakage is a leading cause of industrial emissions. Polyester fiber has revolutionized “Packing” in two ways:

Pure Polyester Packing: Braided fibers impregnated with PTFE (Teflon) provide a low-friction seal for water, oil, and mild chemicals.

Hybrid Braiding: By blending polyester with high-performance fibers like Aramid (Kevlar) or Graphite, engineers create “composite packings” that handle pressures up to 10 MPa and resist the aggressive scouring of steam and chemical slurries.

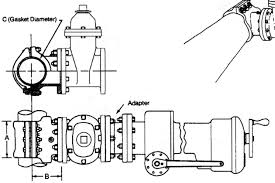

B. Reinforced Gaskets and Diaphragms

In high-vibration systems, standard rubber gaskets can tear. By embedding a polyester fiber mesh (fabric reinforcement) into Nitrile (NBR) or Viton (FKM) rubber, the resulting gasket gains immense tensile strength and tear resistance, making it ideal for municipal water and HVAC systems.

C. Wear-Resistant Bushings and Guide Sleeves

Large-diameter gate valves often suffer from “stem galling”—where metal-on-metal friction causes the stem to seize.

The Solution: Bushings made from Polyester-reinforced composites (often mixed with PTFE or Nylon) offer a service life 3–5 times longer than traditional bronze bushings. In a municipal case study, a DN1000 gate valve saw its operating torque drop from 80 N·m to 50 N·m after switching to polyester composite guides.

D. High-Strength Filtration Elements

For valves operating in “dirty” media (slurries, circulating cooling water), polyester non-woven filters are installed at the inlet. With filtration precision ranging from 1–100μm, these elements protect the valve seat from scratches caused by sand and rust particles.

3. The Comparative Advantage: Why Choose Polyester?

| Feature | Polyester (PET/PBT) | Traditional (Asbestos/Metal) |

| Environmental Safety | Non-toxic, Asbestos-free. | Health hazards (Asbestos). |

| Friction | Very Low (Low torque). | High (Requires more power). |

| Maintenance | Self-lubricating, non-galling. | Requires frequent lubrication. |

| Cost | High (Initial) / Low (TCO). | Low (Initial) / High (Maintenance). |

4. Limitations and Engineering Constraints

While versatile, polyester is not a “universal” solution. Engineers must account for:

Temperature Ceilings: It cannot replace graphite or metallic seals in high-temperature steam applications exceeding 150°C.

Chemical Sensitivity: It will degrade in the presence of concentrated strong acids (sulfuric/nitric) or strong alkalis over long periods.

Moisture Absorption: A slight regain (approx. 0.4%) can lead to minor dimensional changes in ultra-high-precision environments.

5. The Horizon: Intelligence and Sustainability

The future of polyester in the valve industry is moving toward Functionalization:

Smart Seals: Researchers are embedding sensors into polyester-fiber-reinforced seals to monitor wear levels and temperature in real-time, feeding data back to PLC systems for Predictive Maintenance.

Nano-Composites: Blending PET with Nano-Silica or Graphene to push the temperature resistance toward the 200°C mark, allowing it to compete with expensive specialty fibers.

Green Chemistry: The shift toward PLA (Polylactic Acid)-based bio-polyesters for valves used in eco-sensitive water treatment plants, ensuring that the components are eventually biodegradable or easily recyclable.

Final Verdict for Plant Managers

Polyester fiber is no longer just a “cost-saving” material; it is a performance multiplier. By reducing friction, preventing corrosion, and providing a safer, asbestos-free working environment, polyester-integrated valves represent the next step in sustainable and efficient fluid control.