In the world of fluid power, the ability to graduate flow and pressure is essential for sophisticated automation. If you’ve ever wondered, “How does a proportional valve work?” or why it’s superior to a standard on/off solenoid, this guide breaks down the physics and engineering behind this critical component.

Table of Contents

Toggle1. The Core Working Principle: Electromagnetics into Linear Motion

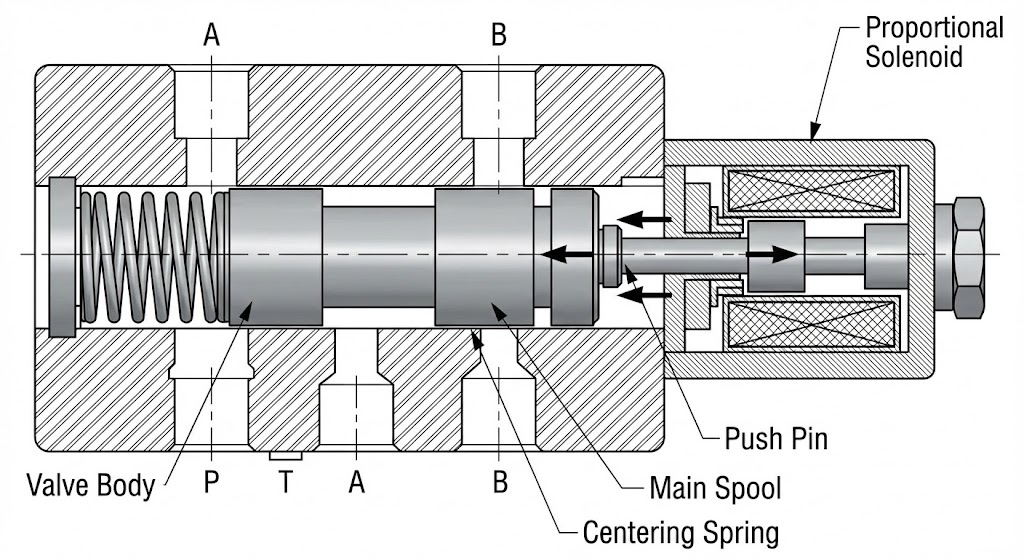

The fundamental proportional valve function is to convert a variable electrical signal into a corresponding mechanical position. Unlike a standard solenoid valve—which uses a simple coil to pull a plunger to a fixed stop—a proportional valve utilizes a proportional solenoid.

The Physics of the Proportional Solenoid:

Variable Current: The proportional valve controller sends a pulse-width modulated (PWM) current to the valve’s coil.

Controlled Magnetic Field: As the current increases, the magnetic field strength grows.

Balanced Force: The solenoid exerts a force on the valve spool. This force is opposed by a precision spring.

Infinite Positioning: The spool moves to a position where the magnetic force and the spring force reach equilibrium. Because the current is infinitely adjustable, the spool position is infinitely adjustable.

2. Understanding the Proportional Valve Diagram

To design a system, an engineer must be able to read a proportional valve diagram. In hydraulic and pneumatic schematics, these valves are identified by unique symbols.

The Envelope: A series of squares representing the valve’s flow paths.

Parallel Lines: Two horizontal lines drawn above and below the valve envelopes indicate that the valve has an infinite number of positions (proportionality).

The Solenoid Symbol: A diagonal line through the solenoid box indicates it is variable, not just a binary switch.

3. The Control Ecosystem: The Controller is Key

A proportional valve cannot operate in isolation; it requires a proportional valve controller (or driver card). This device performs several critical functions:

Signal Conversion: It takes a 0-10V or 4-20mA signal from a PLC and converts it into a high-current PWM signal.

Dither: It adds a high-frequency vibration to the signal. This “dither” keeps the spool in constant micro-motion, eliminating hysteresis and static friction (stiction), ensuring the valve responds instantly to small signal changes.

Ramp Control: It allows the user to set how fast the valve opens or closes, protecting the system from sudden pressure spikes.

4. Application Areas: Beyond Oil Hydraulics

While the term “proportional hydraulic valve” is most common, the technology is essential across various media:

Pneumatic Proportional Valves

In factory automation, a pneumatic proportional valve is used to control air pressure for tensioning systems in paper mills or for high-speed sorting arms. They offer the speed of air with the precision of electronics.

Proportional Valve for Water

In advanced cooling systems or chemical dosing, a proportional valve for water ensures that the flow rate is adjusted based on real-time temperature or pH sensors. This prevents the “thermal shock” associated with traditional on/off water valves.

5. Why Choose Proportional Over Conventional?

If your application requires soft-start/soft-stop, constant speed under varying loads, or remote pressure adjustment, a proportional valve is the only solution. It reduces mechanical wear by eliminating hydraulic shock and increases the “intelligence” of your machinery.

Conclusion

Understanding the proportional valve working principle is the first step in optimizing any automated fluid system. By mastering the relationship between current, magnetic force, and spool position, engineers can design systems that are faster, smoother, and more reliable.