Table of Contents

ToggleAncient Origins: Before 200 BC to Early 17th Century

The earliest applications of hydraulic technology can be traced back over 2,200 years. The Greeks invented spiral water-lifting tools, while ancient China developed water wheels for irrigation and milling purposes. These primitive applications represented humanity’s first attempts to harness fluid power for practical work, laying the conceptual foundation for modern hydraulic systems.

The Scientific Foundation: 17th to 19th Century

Theoretical Breakthroughs

The period from the 17th to 19th centuries witnessed European scientists and engineers making fundamental contributions to fluid mechanics, fluid transmission, mechanism theory, control science, and mechanical manufacturing. Several landmark achievements during this era established the scientific basis for modern hydraulic technology:

1648 – French mathematician and physicist Blaise Pascal formulated Pascal’s Law, the fundamental principle of pressure transmission in fluids. This law states that pressure applied to a confined fluid is transmitted equally in all directions, which remains the core operating principle of all hydraulic systems today.

1681 – Denis Papin invented the pressure vessel equipped with a safety valve, introducing the crucial concept of pressure relief and system protection that would later evolve into modern relief valves.

1795 – English engineer Joseph Bramah registered the first patent for a hydraulic press in Britain, demonstrating the practical application of Pascal’s principle for force multiplication.

1850 – British engineer William George Armstrong invented the hydraulic accumulator, enabling energy storage and providing smooth, continuous power delivery in hydraulic systems. This innovation was crucial for early industrial hydraulic applications.

Mid-19th Century – British engineer Fleeming Jenkin developed the world’s first pressure-compensated flow control valve, introducing the concept of maintaining constant flow despite pressure variations—a principle still fundamental to modern hydraulic control.

These contributions and achievements provided both the scientific understanding and practical techniques necessary for the 20th-century development of hydraulic transmission and control technology.

The Water Era and Its Challenges: 19th Century

Throughout the 19th century, industrial hydraulic systems used water as the working medium. However, this approach faced significant limitations:

- Sealing problems: Water’s low viscosity made effective sealing extremely difficult with the materials and manufacturing techniques available at the time

- Corrosion issues: Water caused rust and corrosion in metal components

- Freezing concerns: Water-based systems were unsuitable for cold climates

- Competition from electrical technology: The rapid development of electrical transmission and control systems offered viable alternatives

These challenges led to a period of stagnation in hydraulic technology development. The situation remained largely unchanged until a crucial breakthrough in the early 20th century.

The Oil Revolution: Early 20th Century

The turning point came in 1905 when American engineer Janney pioneered the use of mineral oil instead of water as the hydraulic medium. This innovation solved many of the persistent problems:

- Superior lubrication properties

- Better sealing characteristics

- Corrosion resistance

- Wider operating temperature range

- Higher viscosity for reduced leakage

This transition from water to oil marked the beginning of modern hydraulic technology and enabled the development of more sophisticated and reliable hydraulic systems.

Rapid Development: 1930s and World War II Era

Power Transmission Innovations

The 1930s saw significant advances driven by demands from the vehicle, aviation, and marine industries. Key developments included:

- Swash plate and bent-axis axial piston pumps: Enabling variable displacement and improved efficiency

- Radial and axial hydraulic motors: Providing compact, high-power rotary actuation

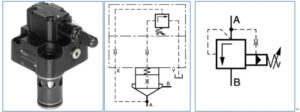

- Pilot-operated pressure valves: In 1936, Harry Vickers invented the pilot-operated pressure control valve, introducing the cartridge-type series of hydraulic control elements that revolutionized valve design

Foundation of Servo Technology

The 1930s also witnessed critical innovations that would lead to servo valve development:

- Askania Company (Germany) invented the jet pipe valve principle

- Foxboro Company developed the nozzle-flapper valve

- Siemens (Germany) introduced the double-input valve

These technologies laid the groundwork for the birth of electrohydraulic servo valves.

World War II Acceleration

During World War II, military requirements dramatically accelerated hydraulic technology development. The need for precise weapons control, aircraft flight controls, and naval systems drove the creation of:

- Electrohydraulic servo systems: Offering fast response and high precision

- Advanced hydraulic control elements: Capable of meeting demanding military specifications

- Sophisticated control systems: Integrating hydraulics with emerging electronic technologies

This period transformed hydraulics from primarily a power transmission technology into a precision control technology, setting the stage for post-war commercial applications.

Post-War Expansion: 1950s

Transition to Civil Industry

The 1950s marked hydraulics’ rapid transition into civilian industrial applications as global economies recovered and industrial automation expanded. Hydraulic technology found widespread adoption in:

- Mechanical manufacturing and assembly lines

- Material handling and lifting equipment

- Construction machinery

- Marine vessels

- Aviation systems

Academic and Industrial Progress

Significant research advances occurred at leading institutions:

Technical University of Aachen (Germany) – Made breakthroughs in copying lathe technology using hydraulic control

Massachusetts Institute of Technology (MIT) – Scholars including Blackburn, Lee, and Shearer conducted pioneering research in electrohydraulic servo valves, publishing the influential book “Fluid Power Control” that became a foundational text in the field

The pilot-operated pressure control valve structure invented by Harry Vickers in 1936 continued to be refined and is still widely adopted worldwide today.

Servo Valve Milestones

1950 – W.C. Moog invented the single-nozzle two-stage servo valve, founding what would become Moog Inc., a leader in motion control technology

1955 – T.H. Carson developed the mechanical feedback two-stage servo valve; W.C. Moog introduced the double-nozzle flapper two-stage servo valve, which became a classic design standard still used today

1957 – R. Atchley developed the two-stage jet pipe servo valve

1959 – Introduction of the three-stage electrical feedback servo valve, further enhancing performance and reliability

These innovations established the fundamental architectures for modern servo valves and enabled precise electrohydraulic control for industrial and aerospace applications.

Diversification and Integration: 1960s-1970s

New Valve Configurations

The 1960s brought important structural innovations:

- Plate-mounted and stack valves: Enabling compact manifold designs and reducing piping complexity

- Proportional control valves: Using proportional solenoids as electro-mechanical converters, these valves bridged the gap between simple on-off valves and expensive servo valves

- Industrial adoption: Proportional valves improved contamination resistance and offered better cost-performance ratios, making sophisticated control accessible to a wider range of applications

Cartridge Valve Revolution

The 1970s saw the emergence of cartridge-type (logic valve) hydraulic components, which offered:

- High flow capacity in compact packages

- Reduced pressure drops

- Modular system design

- Simplified maintenance

- Cost-effective implementation for high-power applications

The Digital Era: 1980s Onward

Mechatronics Integration

From the 1980s, hydraulic technology began deep integration with:

- Modern mathematics and mechanics: For better modeling and prediction

- Microelectronics: Enabling embedded intelligence

- Computer technology: For system monitoring and optimization

- Control science: For advanced closed-loop control strategies

This convergence produced mechatronic products integrating:

- Microprocessors

- Electronic amplifiers

- Sensors and measurement elements

- Hydraulic control units

Example: Lee Company (USA) developed miniature hydraulic valves with integrated electronics, demonstrating the potential of highly integrated hydraulic control systems.

Enhanced Capabilities

These developments significantly improved:

- System intelligence: Self-diagnostics, adaptive control, condition monitoring

- Reliability: Reduced component count, electronic validation, predictive maintenance

- Performance: Faster response, higher precision, better repeatability

Computer-Aided Design and Simulation

Computer technology enabled:

- Digital simulation of static and dynamic performance of hydraulic components and systems

- CAD/CAM for component and system design and manufacturing

- Optimization algorithms for system design

- Virtual prototyping reducing development time and costs

Environmental Renaissance: Pure Water Hydraulics

Renewed Interest

Over the past 20 years, growing environmental awareness and energy crisis concerns have sparked renewed interest in pure water hydraulics—ironically returning to the original working medium of 19th-century systems, but with modern technology:

- Environmental benefits: Non-toxic, non-flammable, readily available

- Food and pharmaceutical applications: Contamination-free operation

- Fire safety: Critical for mining and other hazardous environments

Modern Development

Pure water hydraulic technology has achieved:

- Steady theoretical progress: Better understanding of tribology, materials, and sealing

- Practical applications: Successful implementation in niche markets

- Recognition as emerging technology: Identified as a promising future direction for hydraulic systems

Advanced materials, coatings, and seal designs have overcome many historical limitations, making water hydraulics viable for specific applications where its unique properties offer distinct advantages.

Expanding Application Domains

Hydraulic technology has permeated virtually every sector of the national economy:

Manufacturing and Processing

- Machining and assembly lines

- Material rolling and plastic molding equipment

- Material and component testing machines

- Electrohydraulic simulation platforms

Energy and Resources

- Power generation equipment

- Coal mining machinery

- Oil and gas exploration and production

- Chemical processing equipment

- Steel and metallurgical facilities

Construction and Infrastructure

- Construction and engineering machinery

- Agricultural equipment

- Environmental protection systems

Transportation

- Aviation and aerospace control systems

- Marine vessels

- Railway vehicles

- Highway transport vehicles

Consumer and Commercial

- Light industry: rubber, leather, paper manufacturing

- Home appliances

- Electronic product automated production lines

- Printing and office automation equipment

- Food processing machinery

- Medical devices

- Entertainment, recreation, and sports training equipment

Hydraulic transmission and control has become a fundamental element of modern mechanical engineering and one of the key technologies in engineering control.

The 21st Century: New Frontiers

Driving Forces

The 21st century is characterized by:

- Informatization: Data-driven decision making

- Networking: Connected systems and Industry 4.0

- Knowledge economy: Innovation-driven development

- Globalization: Worldwide collaboration and competition

Emerging Technologies Impact

New scientific and technological advances are profoundly influencing hydraulic valve research, design concepts, and methods:

- Information technology: IoT sensors, cloud connectivity, big data analytics

- Life sciences and biotechnology: Bio-inspired designs, biomimetic materials

- Nanotechnology: Advanced coatings, nanofluid additives, micro-scale components

These technologies are transforming:

- Hydraulic product structures and manufacturing processes

- Application fields and use cases

- Enterprise management models and business operations

Future Development Trends

Under strong demand from society and engineering applications, and facing challenges from mechanical and electrical transmission systems, hydraulic transmission and control technology will continue evolving by:

1. Leveraging Core Technologies

- Advanced manufacturing

- Materials engineering

- Microelectronics and computing

- Mathematics and mechanics

- Control science

2. Embracing Key Development Directions

Green/Environmental Technology

- Biodegradable fluids

- Energy-efficient designs

- Reduced emissions

- Recyclable materials

- Lower noise levels

Mechatronics Integration

- Seamless hardware-software integration

- Embedded intelligence

- Self-configuring systems

- Digital twins

Modularization

- Standardized interfaces

- Interchangeable components

- Scalable systems

- Simplified maintenance

- Reduced inventory

Intelligent Systems

- Predictive maintenance

- Self-optimization

- Adaptive control

- Machine learning integration

- Autonomous operation

Networking and Connectivity

- Industrial IoT integration

- Remote monitoring and diagnostics

- Cloud-based analytics

- Digital ecosystems

- Cyber-physical systems

Conclusion

From ancient water wheels to intelligent networked hydraulic systems, hydraulic valve technology has undergone a remarkable 2,200-year journey. Each era brought innovations driven by the needs of its time—from Pascal’s fundamental laws to Moog’s servo valves, from simple pressure relief to intelligent proportional control.

Today’s hydraulic valves represent the culmination of centuries of scientific discovery, engineering innovation, and practical experience. As we move deeper into the 21st century, hydraulic technology continues to evolve, integrating with cutting-edge digital technologies while addressing critical challenges of energy efficiency and environmental sustainability.

The future of hydraulic valve technology lies not in replacing existing solutions but in intelligent enhancement—making systems smarter, more efficient, more sustainable, and more connected. As industries worldwide pursue automation, precision, and sustainability, hydraulic transmission and control technology, with valves at its heart, will continue playing a vital role in advancing human capability and improving quality of life.

The journey from Pascal’s pressure vessel to today’s intelligent electrohydraulic systems demonstrates that while the fundamental physics remains unchanged, human ingenuity continually finds new ways to harness fluid power more effectively, efficiently, and intelligently. This evolution will undoubtedly continue, pushing hydraulic technology to new levels of performance and opening applications we have yet to imagine.