Table of Contents

ToggleWhy Choose Socket Weld Components?

In small-bore piping systems (typically 2 Inch and smaller), the socket weld connection is the industry favorite. Whether you are dealing with a socket weld flange or various socket weld fittings, these components provide a leak-proof, high-integrity joint that is far superior to threaded connections in high-pressure or hazardous services.

This article explores the structural advantages, installation best practices, and material options for these essential piping components.

I. What is a Socket Weld Flange (SW Flange)?

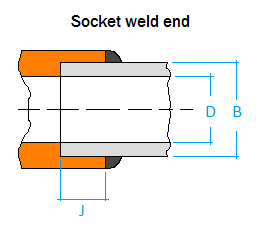

A socket weld flange is a specialized flange originally developed for use on small-size, high-pressure piping. It features a recessed socket in the hub, which acts as a guide for the pipe.

Key Structural Features:

The Internal Shoulder: The flange has a bore and a counterbore. the pipe is inserted into the counterbore until it hits the shoulder, ensuring a stable seat.

The Fillet Weld: Once inserted, a fillet weld is applied to the outside of the pipe and the hub of the flange.

Flow Efficiency: When properly installed, the internal bore of the pipe matches the bore of the flange, providing a relatively smooth flow path compared to threaded flanges.

II. Essential Socket Weld Pipe Fittings

Beyond flanges, a complete piping system requires a variety of socket welding pipe fittings to change direction or branch off.

SW Elbows (90° & 45°): Used for changing the direction of the flow.

SW Tees: Used for branching the line.

SW Couplings & Caps: Used for joining pipe lengths or sealing the end of a line.

SW Unions: Designed for applications that require frequent disassembly for maintenance.

III. The “Critical Gap” in Socket Welding

Whether you are installing a socket weld pipe fitting or a flange, there is one rule that cannot be ignored: The 1.6mm (1/16 Inch) Expansion Gap.

As discussed in our welding guide, the pipe must not be bottomed out against the shoulder during the final weld.

Insert the pipe into the socket until it touches the shoulder.

Back it out by 1.6mm.

Perform the weld.

This gap prevents the pipe from expanding against the fitting during the heat of welding, which could otherwise lead to stress cracks in the weld bead.

IV. Material and Pressure Standards

Our socket weld fittings catalog covers a wide range of industrial requirements:

Material Grades: Available in Forged Carbon Steel (ASTM A105), Stainless Steel (304/304L, 316/316L), and high-performance alloys like Duplex or Inconel.

Pressure Ratings: Common ratings include 3000#, 6000#, and 9000# for forged fittings, and Class 150 to 2500 for socket weld flanges.

Standards Compliance: All parts are manufactured to conform to ASME B16.11 (forgings) and ASME B16.5 (flanges).

V. Advantages of SW Flanges vs. Other Types

| Comparison | Advantage of Socket Weld |

| vs. Threaded Flange | Better leak resistance in high-pressure and temperature-cycling services. |

| vs. Slip-On Flange | Only requires a single fillet weld on the outside, whereas Slip-Ons often require two. |

| vs. Butt Weld Flange | Easier to align; no need for beveled ends on the pipe. |

Conclusion: Reliability in Small Packages

The socket weld flange and its associated socket welding fittings are the backbone of small-bore, high-integrity piping. By combining the ease of alignment with the strength of a welded joint, they provide a long-lasting solution for critical industrial applications.