Once you’ve identified a leak or a sticking pedal, the next question is: Can I just fix it, or do I need a whole new valve? Because the air brake foot valve is a precision-engineered safety component, the answer isn’t always about price. In this buyer’s guide, we compare the pros and cons of treadle valve repair kits versus full air brake valve replacement to help you minimize downtime and maximize safety.

Table of Contents

Toggle1. The Case for the Air Brake Foot Valve Repair Kit

A repair kit (or “major maintenance kit”) typically includes the internal rubber O-rings, seals, diaphragms, springs, and lubricant.

Pros:

Cost-Effective: Usually 30-50% cheaper than a complete valve assembly.

Environmental: Reuses the heavy metal casting, reducing waste.

Storage: Easier to keep in your truck’s emergency toolbox for “on-the-road” fixes.

Cons:

High Labor Time: Disassembling, cleaning, and reassembling a valve takes significant time.

Risk of Bore Damage: If the internal metal “bore” (the cylinder where the seals slide) is scratched or pitted from road salt or moisture, new seals will fail almost immediately.

Complexity: If you install a seal upside down, the valve may leak even worse than before.

2. The Case for Full Valve Replacement (Recommended)

Replacing the entire unit with a new or remanufactured Bendix foot valve or high-quality aftermarket equivalent is the industry standard for professional fleets.

Pros:

Plug-and-Play: Faster installation (usually under 1 hour).

Guaranteed Integrity: You get a factory-tested unit with a fresh casting, a new plunger boot, and pre-lubricated internals.

Safety First: Eliminates the risk of unseen hairline cracks in the valve body.

Warranty: New valves typically come with a 1-year or mileage-based warranty.

Cons:

Higher Initial Cost: More expensive upfront than a bag of rubber seals.

3. Decision Matrix: Which One Do You Need?

| If you see… | Repair Kit is OK | Full Replacement Required |

| Minor hissing at exhaust | ✅ | |

| Pitting or rust inside the valve bore | ❌ | |

| Stiff or “crunchy” pedal movement | ❌ | |

| Leaking between Primary & Secondary circuits | ❌ | |

| Torn rubber plunger boot | ✅ | |

| Cracked or corroded outer casting | ❌ |

4. What to Look for When Buying a Replacement

If you decide on a full air brake pedal valve replacement, pay attention to these three factors:

Port Orientation: Check your old valve. Are the ports on the side or the bottom? Look for “Vertical” vs. “Horizontal” delivery port configurations.

Cross-Reference Numbers: Modern aftermarket valves are designed to replace Bendix (e.g., E-6, E-8P, E-10) or Wabco units. Match the OEM part number stamped on the valve body.

Certification: Ensure the valve meets FMVSS-121 standards (Federal Motor Vehicle Safety Standards for Air Brake Systems).

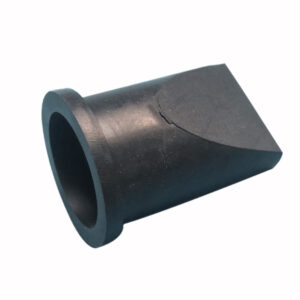

5. Pro Tip: Don’t Forget the Plunger Boot

The #1 cause of treadle valve failure is a torn rubber boot at the base of the pedal. This allows road grime and salt to enter the valve. Whether you repair or replace, always ensure the air brake pedal boot is intact and sealed to prevent future corrosion.

Conclusion: The Professional Choice

While a repair kit is a great tool for an emergency fix or a low-mileage hobby truck, replacing the full valve is the best choice for commercial lorries and heavy-duty trucks. The peace of mind knowing you have a factory-sealed unit is worth the extra investment when you’re hauling 80,000 lbs down a steep grade.