Fuel theft and accidental fuel discharge are common problems in vehicles, boats, generators, and storage tanks. An anti-siphon fuel valve is one of the most effective mechanisms to prevent unauthorized fuel removal and stop reverse fuel flow. Whether you operate a marine vessel, manage fuel storage, or work with automotive equipment, understanding how an anti-siphon fuel valve works can save cost, enhance safety, and protect your fuel system.

This guide explains everything you need to know — from how the valve works to installation tips, types, and common applications.

Table of Contents

Toggle1. What Is an Anti-Siphon Fuel Valve?

An anti-siphon fuel valve is a check-style safety device installed in the fuel line to prevent fuel from flowing backward or being siphoned out of the tank.

It allows normal fuel flow into the engine, but stops flow if someone attempts to withdraw fuel through external suction.

Core Functions

Prevent unauthorized siphoning (fuel theft protection)

Stop reverse flow caused by pressure changes

Maintain stable fuel pressure toward the engine

Enhance safety in automotive and marine fuel systems

2. How Does an Anti-Siphon Fuel Valve Work?

Anti-siphon fuel valves are typically spring-loaded check valves engineered to allow fuel to move in only one direction.

Working Principle

Normal Operation

When the engine fuel pump draws fuel forward, internal pressure pushes the spring-loaded poppet open, allowing smooth one-way flow.Siphoning Attempt

If someone tries to extract fuel from outside the tank, they create suction in the opposite direction.

The valve senses this reverse flow and remains closed, preventing any fuel from leaving.Pressure Drop Protection

In case of sudden pressure change or fuel line rupture, the valve automatically shuts to minimize fuel leakage.

Key Mechanisms

One-way check valve

Spring-loaded poppet

Internal sealing seat

Reverse-flow blockage

This simple but robust mechanism makes it extremely effective for theft prevention and fuel safety.

3. Types of Anti-Siphon Fuel Valves

Anti-siphon valves come in several designs depending on application, fuel type, and safety requirements.

1) Marine Anti-Siphon Fuel Valves

Used in boats and marine engines, often required by U.S. Coast Guard (USCG) regulations.

Features:

Corrosion-resistant brass or stainless steel

Built-in thermal safety (optional)

Protects against fuel spillage in case of fire

2) Automotive Anti-Siphon Valves

Installed in cars, trucks, and heavy equipment to stop fuel theft.

Features:

Inline or tank-integrated

May include baffle tubes or mesh inserts

Designed to withstand vibration and temperature changes

3) Fuel Tank Anti-Siphon Devices (Aftermarket)

Common for tractors, generators, and fuel storage tanks.

Features:

Drop-in or cap-integrated design

Multi-layer internal baffles

Often used in fleet management and construction equipment

4) Anti-Siphon Gas Tank Inserts

Placed in the filler neck to block insertion of siphon hoses.

4. Benefits of Using an Anti-Siphon Fuel Valve

1. Fuel Theft Prevention

Stops siphoning attempts instantly — ideal for fleets, marine vessels, rental machinery, and rural storage tanks.

2. Safety Compliance

Required in many marine applications to prevent fuel spillage.

3. Leakage Protection

Reduces risk of fuel discharge in case of pipeline damage or pressure imbalance.

4. Protects Engine Fuel System

Maintains consistent one-way fuel flow and prevents air from entering the lines.

5. Low Maintenance

Simple mechanical structure with long service life.

5. Common Applications

Anti-siphon fuel valves are widely used across industries:

Marine & Boats

Outboard and inboard engines

Fuel tanks located below deck

Required safety fitting in many regions

Automotive Systems

Cars, trucks, RVs

Heavy-duty construction equipment

Mining vehicles

Fuel Storage Tanks

Remote fuel reservoirs

Generator tanks

Agricultural tanks

Mobile fueling units

Industrial Equipment

Pumps

Compressors

Diesel machinery

Wherever fuel needs protection from reverse flow or theft, an anti-siphon valve is essential.

6. Installation Guidelines

While installation varies by model, general guidance includes:

1) Install As Close to the Fuel Tank as Possible

Prevents siphoning before fuel enters the main line.

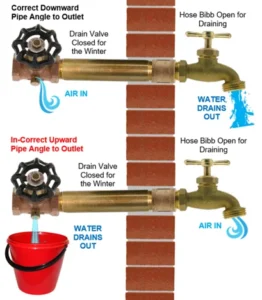

2) Valve Orientation Matters

Follow directional arrows indicating fuel flow direction.

3) Use Compatible Fittings

Choose materials that match the fuel type:

Brass or stainless steel for gasoline/diesel

Aluminum/nylon reinforced options for lightweight setups

4) Check for Pressure Drop

Some valves create slight restriction—choose one sized correctly for your engine’s flow rate.

5) Comply with Marine or Automotive Regulations

Boats: Follow USCG and ABYC standards

Vehicles: Follow OEM guidelines

7. Troubleshooting Anti-Siphon Fuel Valve Issues

1) Engine Starvation or Hesitation

Valve may be too restrictive

Debris clogging internal seat

Incorrect installation angle

2) Hard Starting

Check for air leakage around fittings.

3) Reduced Fuel Flow

Replace worn spring or stuck poppet (if serviceable).

4) Fuel Tank Vacuum Build-Up

Vent line blockage — not usually the anti-siphon valve itself.

8. How to Choose the Right Anti-Siphon Fuel Valve

Consider the following:

Fuel type (gasoline, diesel, ethanol blends)

Flow rate requirements

Marine or automotive certification

Material durability

Installation space constraints

Whether theft prevention or safety is the main goal

For marine applications, always choose USCG-approved valves.

9. Conclusion

An anti-siphon fuel valve is a critical device that:

Prevents fuel theft

Protects tanks from siphon-induced leakage

Improves safety for marine, automotive, and industrial systems

Its simple, reliable one-way design makes it an essential component in any fuel system where reverse flow must be prevented.