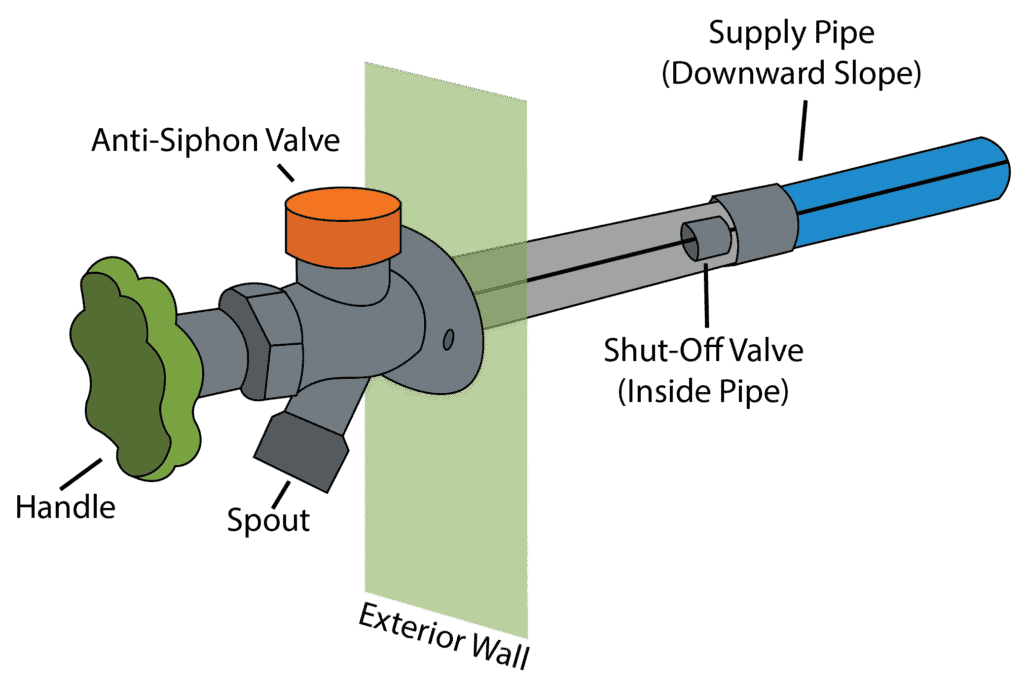

The anti-siphon valve is a deceptively simple yet critical device designed to protect our drinking water supply. Its fundamental purpose is to prevent backflow—specifically, the siphonage of contaminated or non-potable water (like chemicals, standing water, or dirty irrigation water) back into a clean water supply line.

Understanding “how anti siphon valve works” is made easy by dissecting its core components, particularly the atmospheric vacuum breaker (AVB) assembly. This visual explanation simplifies the anti siphon valve diagram and demonstrates its operation in real-world applications.

Table of Contents

Toggle1. Simple Diagram: Inside the Anti-Siphon Valve

A standard residential anti-siphon valve, such as found on a sprinkler system or hose bib, relies on three main functional areas to achieve its goal.

[Imagine a diagram showing a cross-section of an anti-siphon valve (dome on top, flow path below)]

| Component | Function in the Diagram |

| Inlet | The entry point for the clean, pressurized water supply. |

| Outlet | The exit point leading to the non-potable system (e.g., sprinkler heads). |

| Diaphragm/Poppet | The main flexible rubber seal that controls flow between the inlet and outlet. |

| Float/Check Valve | A light component near the top (the atmospheric vacuum breaker) that closes when pressurized but drops open when pressure is lost. |

| Vacuum Breaker Port | A vent hole or opening at the top of the valve dome, normally sealed by the float. |

2. How Each Part Works: The Dynamic Principle

The valve’s anti-siphon protection mechanism only engages when the system is shut down or when supply pressure is lost.

A. System ON (Flowing Water)

Action: When the valve is open and pressurized, water flows from the Inlet to the Outlet.

Float/Check Valve: The supply pressure pushes the float (or poppet) upward, sealing the Vacuum Breaker Port. This prevents water from leaking out the top while the system is running.

Result: The valve allows normal water flow while maintaining pressure.

B. System OFF (Sealing the Flow)

Action: The valve is manually or automatically closed (e.g., solenoid is deactivated). The diaphragm seals the main flow port.

Float/Check Valve: The pressure dissipates, and the float rests on its seal, waiting for potential back-siphonage.

C. The Critical Moment: Preventing Backflow (Siphoning)

Scenario: A sudden loss of pressure upstream (e.g., a burst pipe or the water utility shutting off service) creates a vacuum (negative pressure) in the supply line. This vacuum could suck non-potable water from the Outlet side back into the clean Inlet side.

Float/Check Valve Action: The negative pressure immediately pulls the Float downward, breaking the seal and pulling outside air into the system through the Vacuum Breaker Port.

Result (Why It Prevents Backflow): By introducing a large volume of air into the piping system, the vacuum is broken. The force of the siphon is destroyed, and the contaminated water simply spills harmlessly out of the Vacuum Breaker Port onto the ground, preventing it from ever reaching the main water supply.

3. Applications: Anti-Siphon Faucets and Irrigation

The basic AVB principle is applied in several common household fixtures:

A. Anti-Siphon Faucets (Hose Bibs)

How does an anti-siphon faucet work? It integrates a small, spring-loaded atmospheric vacuum breaker directly into the spout or body of the faucet. If you have a hose submerged in a bucket of soapy water and the supply pressure drops, the AVB opens immediately, sucking air into the faucet body and preventing the dirty water from being siphoned back.

B. Irrigation Valves (Lawn Sprinklers)

The anti-siphon sprinkler valve diagram shows the vacuum breaker built directly into the top bonnet, positioned above the highest point of the irrigation line. This ensures that any back-siphonage is immediately broken by the air vent.

4. Visual Troubleshooting: Locating the Leak Source

Knowing the anti syphon valve diagram helps identify the leak source, which is crucial for quick repairs.

| Leak Location | Likely Cause | Fix |

| Bottom (Constant Flow/Drip) | The diaphragm is unable to seal the main flow port. | Debris on the valve seat or a worn/cracked Diaphragm. |

| Top (Water Spraying/Dripping from Dome Vents) | The Float/Check Valve seal has failed or debris is lodged there. | The small top float/poppet is stuck or its O-ring needs replacement. |

| Between Top/Bottom Housing | The main Bonnet Gasket has failed or the screws are loose. | Tighten screws evenly or replace the Bonnet Gasket. |

The effectiveness of the anti-siphon valve lies in its passive, pressure-sensitive response, providing an automatic and reliable safety barrier the moment the integrity of the water supply is compromised.