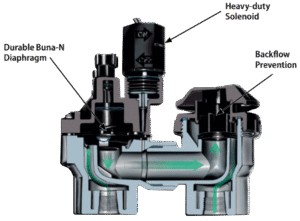

In fluid handling, the term “anti-siphon valve” takes on a critical dual role in fuel systems for marine vessels, large trucks, and backup generators. Unlike their plumbing counterparts which prevent cross-contamination, a fuel tank anti-siphon valve is primarily a security and safety device. It is engineered to permit fuel flow out of the tank while simultaneously preventing two harmful or costly events: reverse flow and siphoning.

Understanding the function and maintenance of the anti-siphon valve for fuel tanks is essential for maintaining both operational safety and fuel security.

Table of Contents

Toggle1. What Anti-Siphon Valves Do in Fuel Systems

The function of an anti-siphon valve fuel tank system is distinct from that in irrigation or plumbing. Its key roles are:

Preventing Gravity Siphoning: The valve acts as a mechanical check valve that prevents fuel from being removed from the tank by simple gravity or suction, whether accidentally or intentionally (theft).

Preventing Reverse Flow: In marine applications, the valve prevents fuel from running backward into the tank when the engine is shut off, which is important for system prime maintenance.

Safety Compliance: On boats, these valves are often mandated by safety regulations (like US Coast Guard rules) to prevent fuel spills in the event a fuel line is cut or damaged.

2. How They Prevent Fuel Theft + Siphoning

Fuel theft via siphoning is a persistent problem for large fleet vehicles, construction equipment, and boats left unattended. The anti-siphon valve fuel tank is a highly effective deterrent.

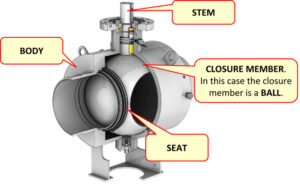

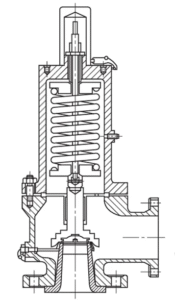

Mechanism: The valve is typically installed directly at the fuel tank outlet (often inside the tank or immediately at the withdrawal tube). It contains a spring-loaded poppet or check ball that requires vacuum pressure (suction from the fuel pump) to open.

Thief Deterrent: If someone attempts to insert a simple tube and use mouth or hand-pump suction (the siphoning action) to draw fuel, the anti-siphon valve will not open, thus blocking the theft attempt. The small, localized vacuum generated by simple siphoning is insufficient to overcome the spring tension of the valve.

3. How Anti-Siphon Valves Work (Fuel Version)

The design principle of the boat gas tank anti-siphon valve is simple and elegant: it relies on the engine’s fuel pump to generate adequate suction.

Engine Off: The spring-loaded poppet is held firmly against the valve seat, creating a tight seal. No fuel can pass through.

Engine Running: The mechanical fuel pump or electric lift pump creates a significant vacuum (suction) in the fuel line. This vacuum overcomes the tension of the spring, pulling the poppet off its seat and allowing fuel to flow freely to the engine.

Engine Shut Off: The vacuum disappears, and the spring immediately pushes the poppet back onto the seat, instantly stopping all flow.

This design ensures that fuel is only withdrawn when the engine demands it under powered suction, preventing both leaks and unauthorized flow.

4. Symptoms of a Bad Anti-Siphon Fuel Valve

While robust, these valves can fail, and their failure typically causes severe performance issues. A failed anti syphon valve fuel system will usually present one primary symptom: Engine Fuel Starvation.

Symptom: The engine runs fine at idle but bogs down, stalls, or refuses to reach high RPMs, particularly when under load (e.g., accelerating a boat).

Diagnosis: This indicates the valve is either sticking closed or the spring tension has increased, meaning the fuel pump cannot pull sufficient fuel through the valve to meet the high demand of the engine. The engine is effectively starving for fuel.

Other Symptoms: Less commonly, if the valve fails to seal, you might notice a very slow gravity leak if the line runs downhill, or difficulties maintaining a fuel prime in the line.

5. Boat Fuel Tank Anti-Siphon Requirements (Expert Insight)

The requirement for an anti-siphon valve is heavily enforced in marine applications due to fire risk.

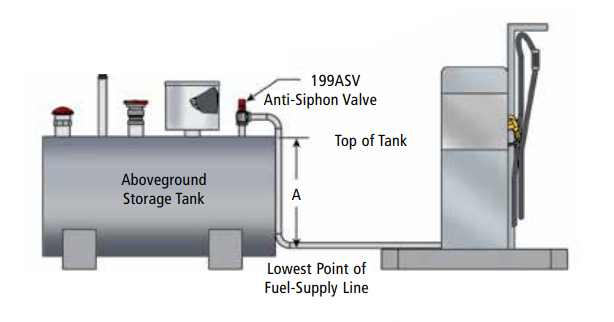

USCG Mandate: Under U.S. Coast Guard regulations (and many international marine standards), any boat with a permanently installed fuel tank where the fuel line runs lower than the tank’s top must be fitted with an anti-siphon valve.

Exemption (Rare): The only typical exemption is if the fuel line is constructed of high-grade barrier hose rated to prevent siphoning, or if the system uses an electric fuel pump that automatically shuts off when the ignition is switched off. For most owners, the valve is mandatory.

6. How to Replace or Bypass (When Legal)

Replacement

Access: The valve is usually located where the fuel line connects to the tank fitting (often hidden under a deck plate on boats).

Procedure: Shut off the fuel supply, disconnect the line, unscrew the old valve fitting, and screw in the new anti-siphon valve for fuel tanks. Always use appropriate fuel-rated thread sealant (not Teflon tape).

Bypassing (Use with Extreme Caution)

In some very old systems or non-critical, land-based systems (check local regulations), a mechanic might temporarily bypass a faulty anti-siphon valve by replacing it with a simple pipe fitting to diagnose the problem.

WARNING: Never bypass this valve on a boat or any system where a fuel leak could cause a fire or explosion, as this violates safety standards and creates a major hazard. Bypassing converts a minor mechanical failure into a major safety liability.

❓ FAQ: Best Anti-Siphon Valves for Fuel Tanks

Q: Are anti-siphon valves required on diesel tanks? A: Typically, no. Diesel engines use lift pumps that often pull fuel directly from a large-diameter pickup tube, and the viscosity of diesel makes siphoning less efficient. However, security-focused valves are available for high-value diesel tanks.

Q: Can I clean a sticking valve? A: Attempting to clean these valves is usually futile and risks permanent failure. Due to their low cost and high safety importance, replacement is always the preferred and recommended repair method.

Q: What is the best anti-siphon valve material? A: Brass or bronze is the standard material due to its compatibility with gasoline and ethanol blends (E10), ensuring longevity and corrosion resistance in marine environments.