A ball check valve for sewage—also known as a sewage ball check valve or spherical sewage check valve—is an essential component in wastewater and drainage pipelines. Its main function is to prevent backflow, ensuring smooth discharge of sewage, sludge, and solid-containing media. Because sewage systems vary widely from domestic plumbing to municipal and industrial networks, ball check valves are available in multiple sizes, pressure ratings, materials, and connection options to match different applications.

This article provides a comprehensive overview of the common specifications and selection criteria for sewage ball check valves.

Table of Contents

Toggle1. Common Specifications of Ball Check Valves for Sewage

✔ Diameter (DN) Range

Ball check valves are typically sized according to pipeline diameter.

Standard range: DN50–DN600 (2″–24″)

Small diameters (DN50–DN150):

Suitable for domestic drainage, small commercial buildings, and light wastewater systems.Large diameters (DN200 and above):

Designed for municipal sewage networks, industrial wastewater treatment plants, and heavy-duty discharge systems.

Choosing the correct DN ensures proper flow capacity and prevents clogging.

2. Pressure Ratings (PN)

Different sewage systems operate under different pressures. Common pressure classes include:

Low-pressure: PN6, PN10

Used in residential or low-pressure drainage systems.Medium to high pressure: PN16, PN25

Suitable for industrial wastewater, pump stations, and high-load discharge pipelines.

Higher pressure ratings ensure safety in systems with strong pumping forces or long-distance discharge.

3. Materials Used in Sewage Ball Check Valves

Material selection affects durability, corrosion resistance, and suitability for different sewage types.

Valve Body / Ball Materials

Cast iron (HT200):

Cost-effective for general sewage applications.Ductile iron (QT450):

Higher strength and better impact resistance.Stainless steel (304 / 316):

Ideal for corrosive sewage, chemical wastewater, or industrial environments.PP (Polypropylene):

Lightweight, corrosion-resistant, and suitable for acidic or alkaline sewage.

Seal Materials

NBR (Nitrile rubber):

Excellent oil-resistance; commonly used in household and industrial sewage.EPDM:

Strong corrosion and chemical resistance; suitable for wastewater with disinfectants or mild chemicals.FKM (Viton):

High-temperature and chemical-resistant for demanding applications.

Proper material selection extends valve lifetime and prevents leakage or failure.

4. Connection Methods for Sewage Ball Check Valves

Depending on pipeline design and installation space, the connection type may vary.

✔ Flanged Connection

Most common for DN50–DN600

Compliant with standards such as GB/T 17241, DIN, and ANSI B16.1

Strong sealing and easy maintenance

Ideal for municipal and industrial systems

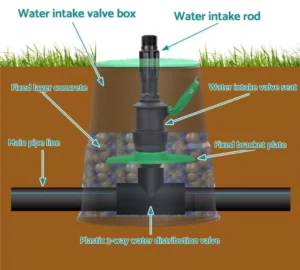

✔ Threaded Connection

Used in small diameters (DN50 and below)

Suitable for residential plumbing and compact installations

✔ Wafer (Clamp) Connection

Compact and lightweight design

Saves space and installation cost

Often used in pump rooms or tight mechanical spaces

Each connection type should be selected based on pressure rating, installation environment, and maintenance needs.

5. Why Choose a Ball Check Valve for Sewage?

Ball check valves offer several advantages:

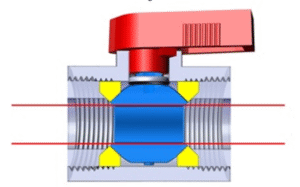

Simple structure with only one moving part (rubber-coated ball)

→ Less chance of failure and cloggingSelf-cleaning function

The ball rotates during operation, preventing debris from stickingReliable backflow prevention

Ensures sewage flows one way, protecting pumps and pipelinesWide media compatibility

Effectively handles solid-containing sewage, sludge, and industrial wastewater

These benefits make ball check valves ideal for harsh sewage environments.

6. Typical Applications

Ball check valves for sewage are widely used in:

Domestic drainage systems

Municipal wastewater networks

Industrial sewage treatment plants

Pump stations and lift stations

Food processing and chemical wastewater pipelines

Mining, paper mills, and sludge-handling systems

Conclusion

A ball check valve for sewage must be selected based on pipe diameter (DN), pressure rating (PN), materials, and connection type. With sizes from DN50 to DN600, pressures from PN6 to PN25, and options in cast iron, ductile iron, stainless steel, and PP, sewage ball check valves can be tailored to match any drainage or wastewater system.

Choosing the right specification ensures zero backflow, long service life, and reliable wastewater control.