Table of Contents

ToggleIntroduction: Classifying the Quarter-Turn Powerhouse

Ball valves are the go-to component for quick, reliable flow isolation in fluid systems. While they all share the fundamental quarter-turn (90°) principle, their internal engineering varies significantly. The choice of design—whether the ball is floating or trunnion-mounted, or whether the body is top entry—fundamentally impacts the valve’s pressure capacity, maintenance requirements, and overall cost.

This guide breaks down the essential classifications to help you choose the correct ball valve for your application.

I. Classification by Ball Mounting Method: Support Defines Performance

The method used to support the ball is the most critical design element. It determines how the valve handles system pressure and dictates its size limitations.

1. The Standard: Floating Ball Valve

The Floating Ball Valve is the simplest and most common design. Its name derives from the fact that the ball is not mechanically supported but rather floats within the valve cavity, held in place only by the seat rings and the stem.

How it Seals: When the valve closes, the upstream pressure thrust pushes the ball tightly against the downstream seat. This pressure-assisted sealing is highly effective, but it means the operational torque increases significantly with line pressure.

Application Scope: Floating valves are the industry standard for general utility service and are widely used in residential and commercial plumbing systems. They are typically limited to smaller lines and lower pressure classes.

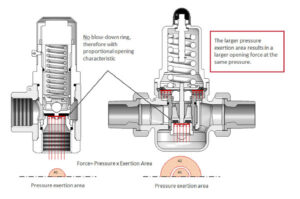

2. The Heavy-Duty Solution: Trunnion Mounted Ball Valve

The Trunnion Mounted Ball Valve is the robust solution designed for high-pressure and large-diameter service. It is engineered to overcome the torque limitations of the floating design.

How it Seals: The ball is secured by a shaft (the trunnion) at the bottom, absorbing the pressure thrust. This mechanical support prevents the ball from pushing forcefully into the seat. Instead, the pressure pushes the seats against the fixed ball.

Performance Advantage: Because the ball is fixed, the operating torque remains low and stable, regardless of the line pressure. This makes them mandatory for high-pressure transmission lines and large-bore piping.

Summary: The core difference is mechanical support: Floating valves rely on fluid pressure for sealing and are torque-limited; Trunnion valves use fixed support for lower, stable torque and handle extreme pressures.

II. Classification by Body Construction: Prioritizing Maintenance

The valve body’s design affects its assembly, strength, and most importantly, its serviceability in the pipeline.

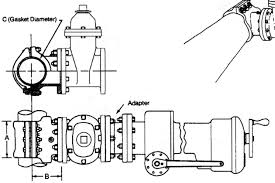

1. Top Entry Ball Valves: Repair Without Removal

The Top Entry Ball Valve design allows for the entire internal assembly—the ball, seats, and stem—to be accessed and removed simply by taking off the bonnet (top cover).

Maintenance Benefit: This is the primary advantage. The valve does not need to be cut out or unbolted from the pipeline for repair, drastically reducing maintenance downtime.

Application: Commonly selected for critical, high-frequency service lines, especially where quick in-line maintenance is essential.

2. Side Entry Body Types (One, Two, and Three-Piece)

The majority of industrial ball valves are side-entry designs, defined by the number of shell pieces used to contain the ball:

One-Piece Body: Simple and economical, but not serviceable in-line. Best for simple, low-cost applications.

Three-Piece Body: Highly favored for maintenance. The center section (holding the ball) can be easily swung out by removing four bolts between the two end pieces, allowing for easy in-line seat and seal replacement without major pipe disruption.

III. Classification by Port Size and Flow Efficiency

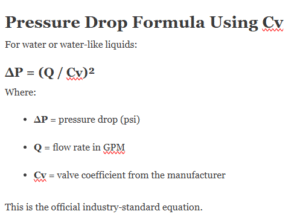

Ball valves are also classified by the size of the bore drilled through the ball, which affects the Cv (flow coefficient) and pressure drop.

1. Full Port (Full Bore)

Flow Path: The bore diameter is exactly equal to the internal diameter of the connecting pipe.

Advantage: Offers the lowest possible pressure drop and is essential for services that require pigging (sending cleaning devices through the line), as there is no restriction.

2. Reduced Port (Reduced Bore)

Flow Path: The bore diameter is one pipe size smaller than the connecting pipeline.

Advantage: More compact, lighter, and lower cost than a full port valve.

Application: General service lines where the minimal increase in pressure drop is acceptable for the cost savings.

IV. Summary: The Final Selection Matrix

Selecting the right ball valve involves prioritizing your operational needs:

| Your Primary Priority | Recommended Design | Why? |

| High Pressure or Large Size | Trunnion Mounted | Stable, low operating torque regardless of pressure. |

| Low Cost / Standard Use | Floating Ball (One/Two-Piece) | Most economical and common design. |

| Fastest In-Line Maintenance | Top Entry or Three-Piece Body | Allows internal servicing without removing the valve from the line. |

| Max Flow Efficiency (Zero $\Delta$P) | Full Port (Full Bore) | Unrestricted flow path. |

Conclusion: The perfect ball valve is a blend of these features. Whether you need the strength of a Trunnion design or the serviceability of a Top Entry valve, understanding these classifications is the first step toward optimizing your fluid system.