In fluid processing, a valve is more than just an on/off switch; it is a precision instrument used to manage flow rates, pressures, and temperatures. While butterfly valves are often chosen for their economic value and high flow capacity, their inherent flow characteristics make them unique compared to globe or gate valves.

For engineers, mastering the relationship between the disc angle and the flow coefficient (Cv) is the key to preventing system instability, cavitation, and premature wear.

Table of Contents

Toggle1. The Inherent Flow Characteristic: Equal Percentage

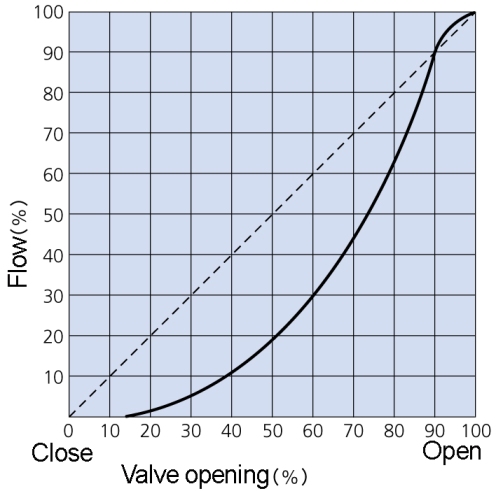

Every control valve has an “inherent flow characteristic”—the relationship between the valve opening and the flow rate under a constant pressure drop.

For the majority of butterfly valves, the inherent characteristic is Equal Percentage.

The Definition: Equal increments of valve travel produce equal percentage changes in the existing flow.

The Benefit: This is ideal for systems where the pressure drop across the valve varies significantly with the flow rate. It provides sensitive control at low flow and rapid capacity increase at high flow.

Note: While the curve is “Equal Percentage” by design, this is only true within the effective control range of the valve.

2. The “Goldilocks” Zone: 30° to 70° Opening

One of the most critical butterfly valve flow characteristics is its effective control range. Unlike globe valves, which can throttle effectively across 90% of their stroke, butterfly valves have specific limitations at both ends of the curve.

The Low-Opening Risk (0° – 30°)

Below a 30° opening, the gap between the disc and the seat is extremely narrow. This creates:

High Velocity: Fluid “jets” through the gap, leading to localized erosion (wire-drawing) of the seat.

Cavitation: The sharp pressure drop at small openings often falls below the vapor pressure of the liquid, triggering destructive cavitation bubbles.

The High-Opening Flatline (70° – 90°)

Above a 70° opening, the disc is nearly parallel to the flow.

Decreasing Sensitivity: At this stage, moving the valve from 80% to 90% open results in a negligible change in flow.

Loss of Control: The valve loses its ability to “control” the process, effectively becoming a fixed resistance in the line.

Engineering Rule: For optimal control, size your butterfly valve so that your maximum required flow occurs at approximately 60% to 70% open, and your minimum flow at no less than 25% to 30% open.

3. Butterfly Valve Flow Curve: Cv vs. Percent Open

The butterfly valve flow curve illustrates the flow coefficient (Cv)—the volume of water in gallons per minute that will flow through a valve with a pressure drop of 1 psi.

At 10% Open: The Cv is very low, but the velocity is dangerously high.

At 50% Open: The Cv typically reaches about 30% to 40% of the valve’s maximum capacity.

At 100% Open: The valve offers a high Cv with very little turbulence, making it excellent for full-flow applications.

4. Butterfly Valve vs. Globe Valve Characteristics

A frequent point of comparison is the globe valve characteristic curve.

Globe Valves are often “Linear,” meaning flow is directly proportional to the valve’s travel. They are superior for high-pressure drops and precision throttling.

Butterfly Valves are more compact and cost-effective for large-diameter pipes. However, because of their disc geometry, they require more careful sizing to avoid the “hunting” (oscillating) effect in control loops.

5. Factors Affecting the Flow Curve in the Field

The “Installed Characteristic” often differs from the “Inherent Characteristic” due to system dynamics:

Pressure Drop (ΔP): As the valve opens, the system’s frictional losses increase, which can distort the equal percentage curve.

Media Viscosity: Thick or viscous fluids will shift the flow curve, requiring a higher Cv for the same opening percentage.

Piping Geometry: As noted in our [Installation Guide], upstream turbulence can cause the disc to vibrate, creating “noise” in your flow data.

Conclusion: Sizing for Success

Understanding butterfly valve flow characteristics is essential for any automated system. By selecting a valve that operates within the 30° to 70° “sweet spot” and recognizing the equal percentage nature of the curve, you can ensure stable control, reduce seat maintenance, and maximize the efficiency of your pneumatic butterfly valves.