Yes — check valves can be installed vertically, but whether it’s appropriate depends on the valve type and the direction of flow.

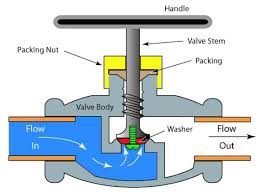

Check valves are designed to allow fluid flow in one direction and automatically prevent reverse flow. They play an essential role in protecting pumps, compressors, and pipelines from backflow damage.

While most check valves are installed horizontally, many types can also be installed vertically — provided that the flow direction is upward and the valve design supports it.

Table of Contents

Toggle1. General Rule for Vertical Installation

A check valve can be installed vertically only when the flow direction is upward.

This ensures that:

Gravity does not keep the disc, ball, or piston closed, and

The fluid pressure can lift the closing element to open the valve properly.

If installed in a downward flow, the valve may fail to open or may close prematurely, leading to flow restriction or vibration.

2. Suitable Types of Check Valves for Vertical Installation

✅ Spring-Loaded or Piston Type Check Valves

These are ideal for vertical installation.

They use a spring to help the disc or piston return to the seat, allowing reliable operation in both horizontal and vertical (upward) positions.

Common applications: Steam, condensate, and high-pressure systems

Examples: Piston check valves, lift check valves with springs

✅ Ball Check Valves

Ball check valves can also be used vertically when the flow is upward. The ball is lifted off its seat by fluid pressure and reseats by gravity or spring when flow stops.

Common in: Wastewater, sump, and slurry applications

⚠️ Swing Check Valves

Swing check valves are generally not recommended for vertical installation unless they are specifically designed for it.

Since the disc swings on a hinge, gravity holds it closed, so in vertical setups it may not open properly or may flutter due to uneven flow.

Use only horizontal orientation unless the manufacturer approves vertical flow.

⚠️ Lift Check Valves (without spring)

Lift check valves rely on gravity to close, so they only work vertically if flow is upward. For downward flow, the disc may remain open, defeating its purpose.

3. Advantages of Vertical Installation

Space Saving: Ideal for compact or vertical piping systems.

Ease of Maintenance: Especially useful in pump discharge lines.

Reduced Backflow Risk: Upward flow direction helps gravity assist closure when the pump stops.

4. Common Mistakes to Avoid

🚫 Downward flow installation:

The valve may not close properly, allowing backflow or creating hammering.

🚫 Installing swing check valves vertically:

Unless the product datasheet specifically states “vertical flow installation allowed,” this setup is unreliable.

🚫 Ignoring flow direction arrow:

Always check the arrow marked on the valve body before installation — it indicates the correct direction of flow.

5. Summary Table

| Valve Type | Vertical Upward Flow | Vertical Downward Flow |

|---|---|---|

| Swing Check Valve | ❌ Not ideal | ❌ Not suitable |

| Lift Check Valve (no spring) | ✅ Possible | ❌ Not suitable |

| Spring-Loaded Lift Check Valve | ✅ Excellent | ⚠️ Limited |

| Piston Check Valve | ✅ Excellent | ⚠️ Limited |

| Ball Check Valve | ✅ Good | ⚠️ Some models only |

6. Conclusion

✅ Yes, check valves can be installed vertically — but only under the right conditions.

The key is ensuring upward flow and selecting a spring-loaded or piston-type valve specifically designed for vertical service.

Swing check valves, on the other hand, should only be installed horizontally unless the manufacturer provides a special vertical-flow design.