Table of Contents

ToggleThe Great Terminology Debate

In the piping and fluid control industry, you will often hear two different names used for the same piece of equipment: the Check Valve and the Non Return Valve (NRV).

For many engineers and procurement managers, this raises a critical question: Is there a functional difference between a check valve vs non return valve, or are they two different components entirely? This guide will settle the debate and explain why the distinction matters for your project.

I. The Short Answer: Is There a Difference?

The short answer is No. In 99% of industrial applications, a Check Valve and a Non Return Valve (NRV) are the exact same thing.

Both terms describe a valve that allows fluid (liquid or gas) to flow through it in only one direction. They are self-activating, meaning they do not require a handwheel or a motor; they use the pressure of the flowing medium to open and the force of gravity or backflow to close.

Why the Two Names?

The difference is purely regional and industrial:

Check Valve: This is the preferred term in North America and is the standard terminology used by the American Petroleum Institute (API) and the American Society of Mechanical Engineers (ASME).

Non Return Valve (NRV): This is the dominant term in the UK, Europe, Australia, and Asia. It is the standard used in British Standards (BS) and European (DIN/ISO) specifications.

II. How Does a Check Valve (NRV) Work?

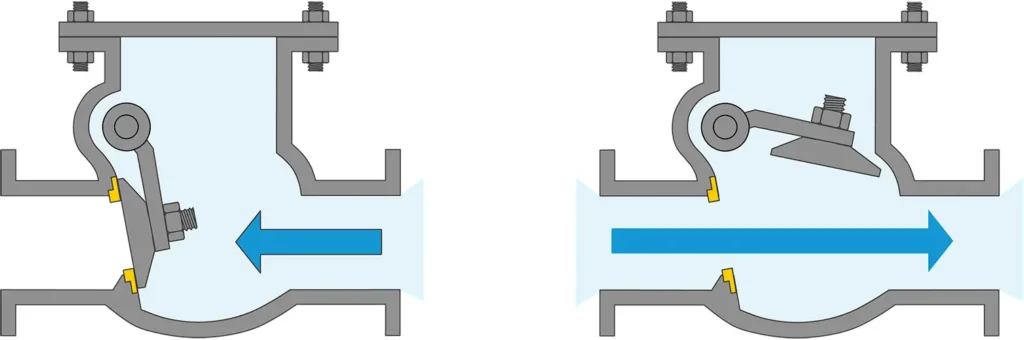

Regardless of the name, the check valve function remains consistent across all designs. It relies on a concept called Cracking Pressure.

Opening (Forward Flow): When the upstream pressure exceeds the “cracking pressure,” it forces the internal disc or ball off its seat, allowing the medium to pass.

Closing (Backflow Prevention): As soon as the pump stops or the flow reverses, the weight of the disc or a spring-loaded mechanism pushes the disc back onto the seat, creating a seal that prevents backflow.

III. Common Types of Check/Non Return Valves

While the names are interchangeable, the designs are not. Selecting the right type of non return valve depends on your piping layout and the nature of the fluid.

1. Swing Check Valve

The most common type, featuring a disc that swings on a hinge or trunnion.

Best For: Low-velocity applications and full-flow requirements.

Industry Hint: Often found in wastewater and large-scale irrigation.

2. Dual Plate Check Valve (Wafer Design)

Features two spring-loaded plates hinged in the center.

Best For: Systems where space is limited and “Water Hammer” must be minimized.

Advantage: Extremely compact and lightweight compared to swing check valves.

3. Lift Check Valve

The disc lifts vertically off the seat. It is similar in internal structure to a globe valve.

Best For: High-pressure service and smaller pipe diameters.

4. Ball Check Valve

Uses a weighted or spring-loaded ball to block the flow.

Best For: Viscous fluids, slurries, or systems where the valve must remain clog-free.

IV. Check Valve vs Non Return Valve: Selection Criteria

When you are looking for a check valve for sale or writing a technical specification, ignore the name and focus on these four parameters:

| Specification | Why It Matters |

| Cracking Pressure | The minimum pressure needed to open the valve. |

| Closing Speed | Faster closing prevents pressure surges (Water Hammer). |

| Installation Orientation | Some valves only work horizontally; others can work vertically (flow up). |

| Material (API 6D/NACE) | Essential for corrosive environments like Oil & Gas. |

V. Summary: Why Both Terms Exist

Check Valve is the “Industry Standard” in Oil, Gas, and Petrochemicals.

Non Return Valve (NRV) is the “Standard” in Water Treatment, HVAC, and Marine Engineering.

Whether you are looking for an API 6D Swing Check Valve or a DIN Standard Non Return Valve, the goal is the same: protecting your pumps and preventing system failure.

Conclusion

The debate of check valve vs non return valve is one of linguistics, not engineering. By understanding that these two terms refer to the same backflow prevention technology, you can navigate international catalogs and standards with confidence.