Table of Contents

ToggleIntroduction

Relief valves serve as the “pressure guardians” of hydraulic systems, functioning as core control elements that ensure safe and stable system operation. Their primary functions revolve around pressure control and can be categorized into three main areas:

Primary Functions

1. Safety Protection This is the most fundamental function of relief valves. When system pressure rises to the valve’s set point due to increased load or circuit blockage, the valve spool opens to discharge excess hydraulic oil back to the tank, maintaining stable system pressure and preventing component damage from overload.

2. Speed Regulation In fixed-displacement pump hydraulic systems, when the flow demand of actuating elements changes, the relief valve functions as a bypass speed control circuit. It directs excess pump output back to the tank, ensuring stable system pressure during throttling and smooth actuator operation.

3. Additional Functions Depending on circuit design requirements, relief valves can perform specialized functions such as remote pressure control through remote control ports, unloading functions when combined with check valves or solenoid valves, and energy-saving applications with compensation features.

Types of Relief Valves

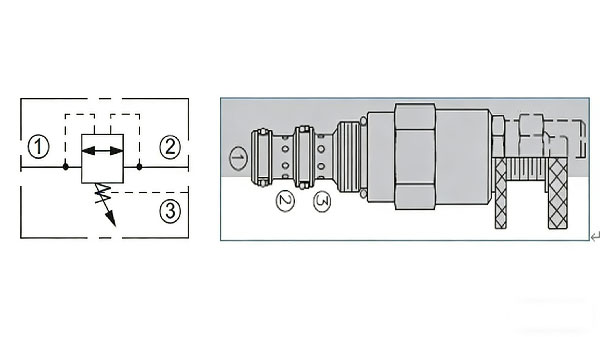

1. Direct-Acting Relief Valve

In its normal state, flow from port ① to port ② is blocked until sufficient pressure at port ① lifts the valve spool from its seat—this pressure is called the opening pressure. When the valve is open, it remains so until pressure drops low enough for the spring to close the valve port; this is the closing pressure, typically 80% of the opening pressure.

Direct-acting relief valves feature simple construction with the spring force acting directly on the valve spool, providing fast response. However, they have relatively poor pressure stability (though some brands incorporate damping structures in the spool for improved stability) and are prone to chattering. These valves are primarily used in low-pressure, small-flow hydraulic systems, as pilot valves for high-pressure relief valves, or as secondary pressure valves for cylinders to filter pressure peaks.

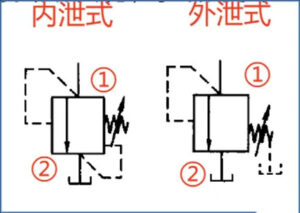

2. Differential Relief Valve

The differential relief valve operates on the same principle as the direct-acting type but with port ② as the high-pressure port. In its normal state, flow from port ② to port ① is blocked. When pressure at port ② is sufficient to overcome the spring force, the valve spool lifts from its seat, allowing overflow from port ② to port ①. This structure can be modified to function as a bidirectional relief valve.

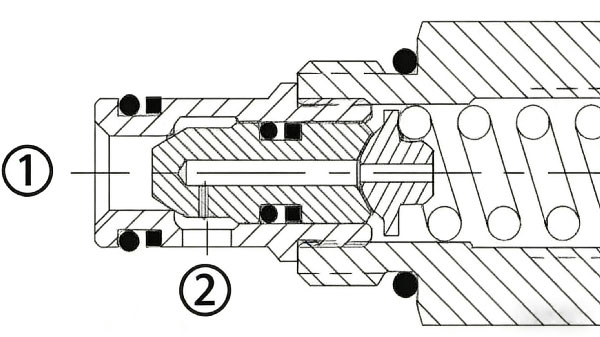

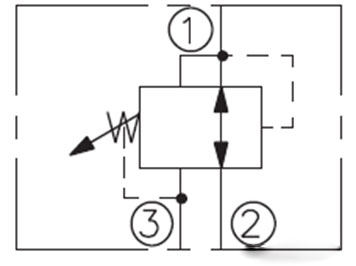

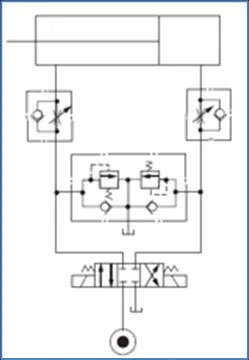

3. Bidirectional Relief Valve (Cross Relief Valve)

The bidirectional relief valve incorporates dual cross protection within the valve spool. When pressure at port ① exceeds the set value, the bottom lift valve spool opens, allowing overflow from port ① to port ②—functioning as a direct-acting relief valve. When pressure at port ② exceeds the set value, the top lift valve spool opens, enabling oil to flow from port ② to port ①—functioning as a differential relief valve. The pressure setting is calibrated at port ②, with the opening pressure difference between both directions not exceeding 1 MPa. Back pressure at either port adds 1:1 to the set pressure value of the other port.

4. Bidirectional Relief Valve with Pressure Release

This valve functions identically to the cross relief valve without pressure release. Back pressure at port ③ adds 1:1 to the set pressure value of the other port.

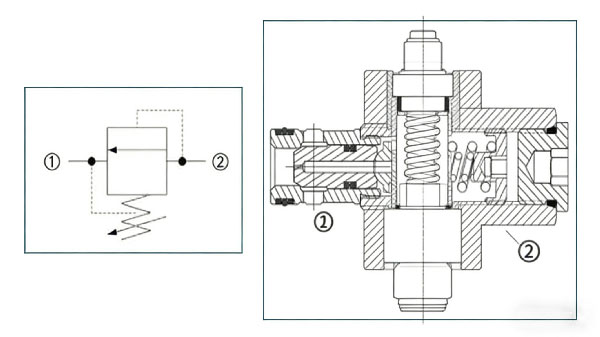

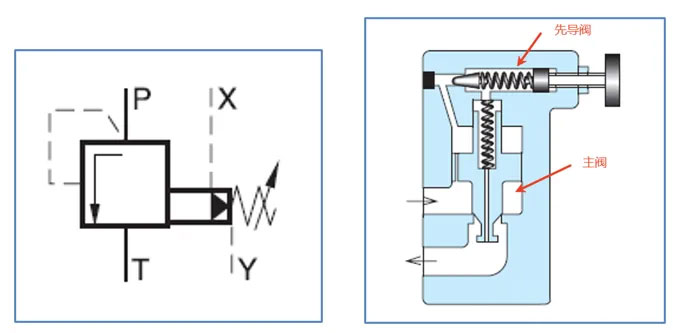

5. Pilot-Operated Relief Valve

Consisting of a pilot valve and main valve, the main valve spool achieves force balance through the combined action of spring force, pilot valve set pressure, and inlet pressure. The main valve spool spring is very soft, resulting in less pressure overshoot compared to direct-acting relief valves (better pressure stability), though with slower response. These valves are suitable for high-pressure, large-flow applications. Pilot-operated relief valves can incorporate a remote control port X for remote pressure adjustment functionality. In some international literature, they are commonly translated as “balanced piston relief valves.”

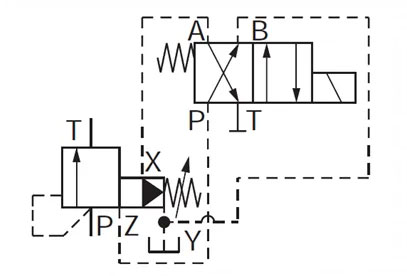

6. Solenoid Relief Valve

By connecting a solenoid valve to the X port of a pilot-operated relief valve, unloading functionality can be achieved when energized (or de-energized).

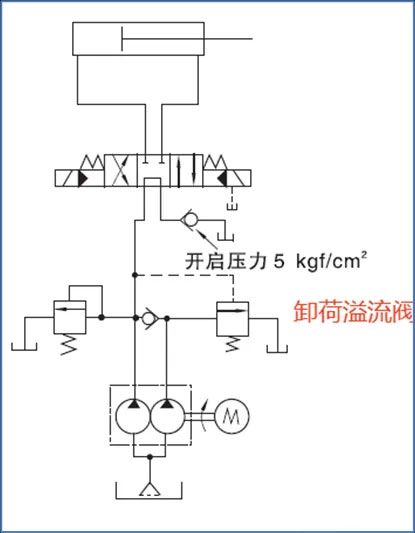

7. Unloading Relief Valve

Typically used in dual-pump systems or accumulator systems, when pressure at port A rises to the valve’s set value, the main valve spool opens, allowing the pump to operate in a low-pressure unloading state.

Unloading relief valves in dual-pump systems effectively reduce installed system power, making them suitable for applications requiring high-pressure small-flow and low-pressure large-flow conditions. This avoids severe “high-pressure large-flow” operating conditions and significantly reduces system energy consumption.

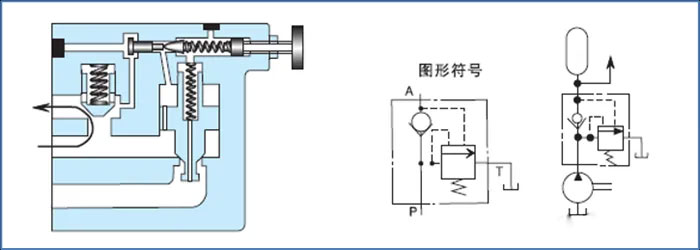

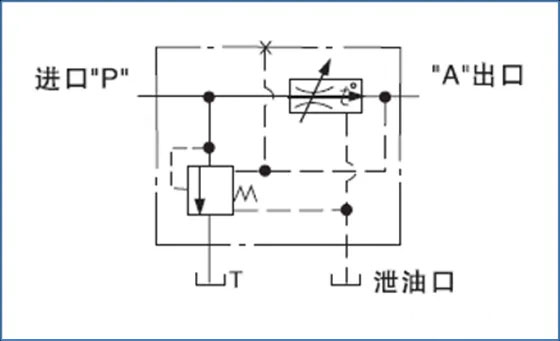

8. Energy-Saving Valve

Also known as a three-way flow valve, this valve is used in fixed-displacement pump systems. Composed of a relief valve and throttle valve, it enables the pump to output only the pressure required by the load plus the compensator spring set value (typically 6-9 bar). This prevents the pump from always operating at maximum system pressure during throttling speed control, thereby reducing energy consumption.

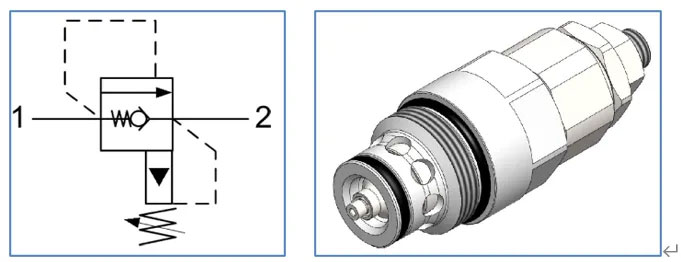

9. Pressure-Reducing Relief Valve

In its normal state, ports ② and ③ allow bidirectional flow, with the spring chamber releasing pressure through port ③. When pressure at port ① reaches the pressure-reducing valve’s set value, the valve spool moves to reduce oil inlet at port ②, preventing further pressure increase at port ①. If pressure at port ① exceeds the set value, it will overflow through port ③. Back pressure at port ③ directly adds to the set value.

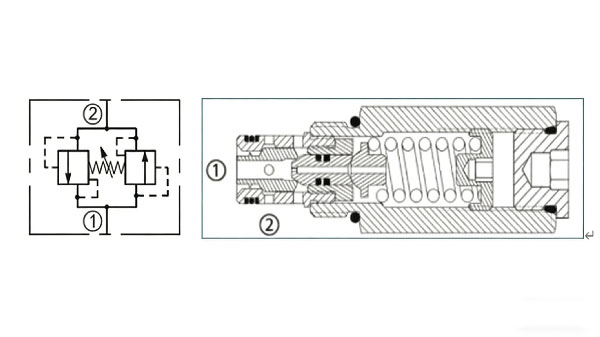

10. Relief Valve with Makeup Function (Anti-Cavitation Valve)

Commonly seen in multi-way valves, this type integrates a check valve in the relief valve spool, enabling makeup flow from port ② to port ①. This prevents cavitation when the cylinder piston moves under external force.

When two such valves are used in parallel with an actuating mechanism, they can form a brake valve. Brake valves are used in braking circuits for actuating elements with significant inertial loads. When the brake valve closes, pressure shocks generated by the actuator’s inertia are absorbed by the brake valve, ensuring smooth motion and stopping. Additionally, these can function as high-pressure relief makeup valves for closed-circuit pumps.

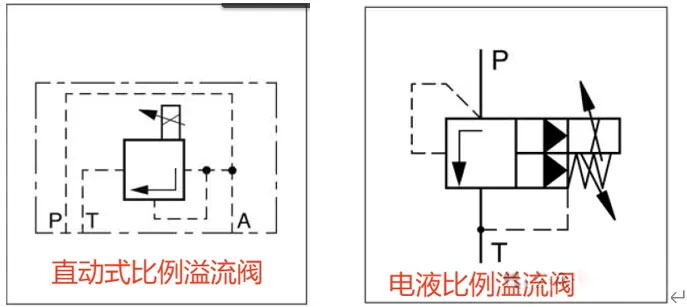

11. Proportional Relief Valve

Traditional hydraulic control valves can only provide fixed pressure control for the system. Multiple relief valves are needed for multiple working pressures. Proportional control valves accept electrical signals as input, making controlled pressure proportional to the input electrical signal, enabling multi-point pressure control and reducing the number of hydraulic components. Proportional relief valves can implement gradual pressure switching through ramp signal settings, avoiding the step-change characteristics of ordinary relief valve pressure switching and eliminating pressure shocks.

Proportional relief valves are also divided into direct-acting and pilot-operated types (electro-hydraulic proportional relief valves). When pressure at port P or port A exceeds the value set by the electromagnet input current, the valve spool opens to connect the pressure release passage to port T, stabilizing pressure at ports P and A at the set value.

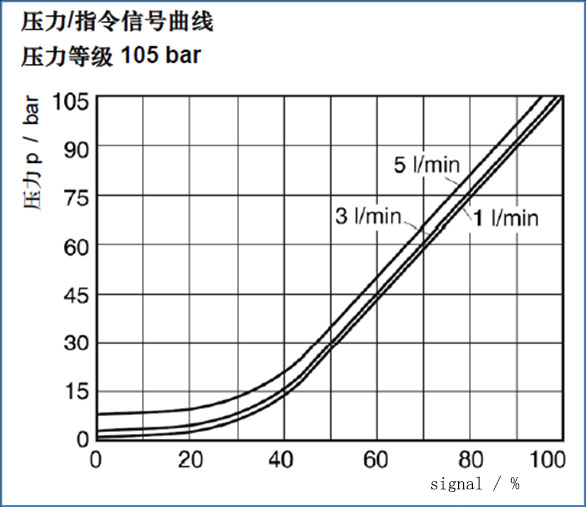

The relationship between input current and pressure for proportional relief valves typically shows a dead zone below 20% voltage/current, with a linear relationship in the 40-100% current/voltage range.

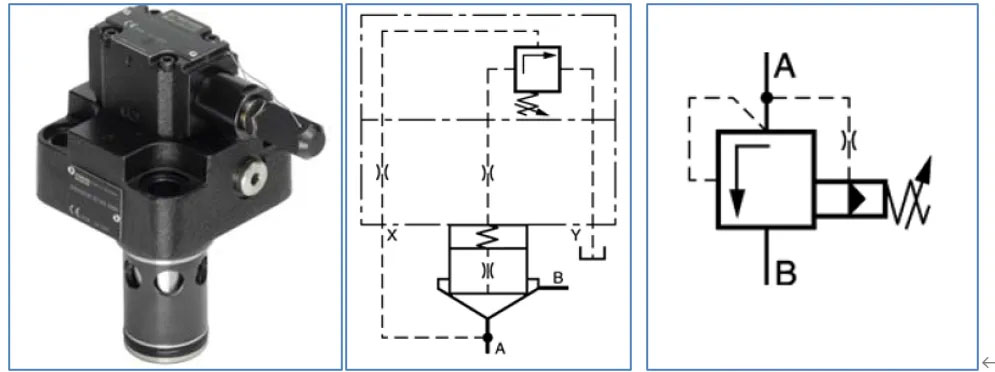

12. Relief Valves Composed of Two-Way Logic Valves

By installing a relief valve in the control chamber of a two-way logic valve, various relief function units can be created: combining with ordinary direct-acting relief valves for standard relief valve functionality, or with proportional relief valves for proportional relief valve functionality.

Two-way logic valves offer high flow capacity and low-pressure loss, making them particularly suitable for high-pressure, large-flow systems. Their spool structure and seal design can withstand high pressure and large flow shocks. Compared to traditional relief valves, they are better suited for overflow requirements in large hydraulic equipment.

Due to the poppet valve structure of the main valve spool, two-way logic valves provide rapid response with no dead zone, fast opening and closing speeds, and effective protection against sudden pressure changes. The poppet valve structure ensures minimal leakage, maintaining stable system pressure while reducing energy loss and oil contamination. These sealing performance advantages are particularly evident in high-pressure environments.

The integrated and modular design achieves high system integration, simplifying system structure and improving reliability. Two-way logic valves feature universal, standardized component design, facilitating selection and replacement with good compatibility across different brands and models, reducing design and maintenance difficulty. Additionally, two-way logic valves demonstrate strong contamination resistance, lowering maintenance costs.

Two-way logic valves, when used as relief valves, combine advantages of large flow capacity, high response, and low leakage, making them an ideal choice for overflow functions in high-pressure, large-flow hydraulic systems. Understanding the various types of relief valves and their specific applications enables engineers to select the most appropriate valve for their hydraulic system requirements, ensuring optimal performance, safety, and energy efficiency.