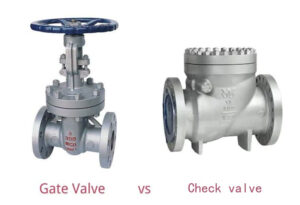

When selecting control valves, you’ll often see two flow coefficients: Kv and Cv.

They both describe how much flow a valve can pass — but they use different units and standards.

The main difference between Cv and Kv values for valves is the unit system: Cv (Imperial) measures flow in US Gallons per Minute (GPM) with a 1 psi pressure drop, used mainly in North America, while Kv (Metric) measures flow in Cubic Meters per Hour (m³/h) with a 1 bar pressure drop, common in Europe and globally. Both quantify a valve’s flow capacity, but using different scales; the relationship is roughly Cv ≈ 1.156 * Kv.

Here’s the full breakdown.

Table of Contents

ToggleQuick Answer

Cv = U.S. flow coefficient (gallons per minute, psi)

Kv = European/metric flow coefficient (m³/h, bar)

Both represent the same physical concept: how easily a valve allows fluid to pass at a given pressure drop.

What Is Cv (Flow Coefficient)?

Cv = the number of U.S. gallons per minute (GPM) of water at 60°F that flows through a valve with a 1 psi pressure drop.

Formula (US system)

Q=CvΔP/SGQ = C_v \sqrt{\Delta P / SG}Q=CvΔP/SG

Where:

Q = flow rate (GPM)

Cv = valve flow coefficient

ΔP = pressure drop (psi)

SG = specific gravity of fluid (water = 1)

Used in:

USA

Oil & gas

HVAC

Industrial piping

Manufacturers like Apollo, Nibco, Watts, etc.

What Is Kv (Metric Flow Coefficient)?

Kv = the number of cubic meters per hour (m³/h) of water at 20°C that flows through a valve with a 1 bar pressure drop.

Formula (metric system)

Q=KvΔP/SGQ = K_v \sqrt{\Delta P / SG}Q=KvΔP/SG

Where:

Q = flow rate (m³/h)

ΔP = pressure drop (bar)

Used in:

Europe

Asia

ISO/EN standards

Pneumatic and industrial valves

Brands like Danfoss, Bürkert, Samson, etc.

Conversion Between Cv and Kv

Because they describe the same physical property, you can convert between them easily.

Cv to Kv

Kv=0.865×CvK_v = 0.865 \times C_vKv=0.865×Cv

Kv to Cv

Cv=1.156×KvC_v = 1.156 \times K_vCv=1.156×Kv

Key Differences (Table)

| Feature | Cv | Kv |

|---|---|---|

| Unit System | U.S. customary | Metric (SI) |

| Flow Unit | GPM (water @ 60°F) | m³/h (water @ 20°C) |

| Pressure Drop | psi | bar |

| Standard | ANSI / ISA | ISO / EN |

| Common Regions | USA, Canada | Europe, Asia |

| Industries | Plumbing, HVAC, industrial | Process control, industrial automation |

| Conversion | Cv × 0.865 = Kv | Kv × 1.156 = Cv |

Which One Should You Use?

Use Cv when:

You work in North America

Specs are in PSI and GPM

Using ANSI/ASME valves

Use Kv when:

You work in Europe or Asia

Specs are in bar and m³/h

You follow ISO or EN standards

For global projects:

Manufacturers usually provide both Cv and Kv ratings.

Example for Clarity

A valve has:

Cv = 10

Convert to Kv:

Kv=0.865×10=8.65K_v = 0.865 \times 10 = 8.65Kv=0.865×10=8.65

Or if you have:

Kv = 12

Convert to Cv:

Cv=1.156×12=13.87C_v = 1.156 \times 12 = 13.87Cv=1.156×12=13.87

Why Cv and Kv Matter

Choosing the correct valve depends on the required flow rate. A valve with:

too low Cv/Kv → insufficient flow

too high Cv/Kv → poor control resolution

Proper calculation ensures:

stable flow

accurate control

minimized pressure loss

energy efficiency

Summary

Cv and Kv measure the same thing: valve flow capacity.

Difference = unit system (U.S. vs metric).

Conversion is simple:

Cv = Kv × 1.156

Kv = Cv × 0.865

Use the coefficient appropriate for your region, industry, or specification standard.