Installing an anti-siphon valve on your outdoor faucet (also known as a hose bib anti-siphon valve) is a critical home plumbing task. This simple device is mandated by most building codes because it protects your family’s drinking water from contamination.

If you are wondering how to install anti siphon valve on outdoor faucet or are preparing for a hose anti siphon valve replacement, this guide provides the step-by-step process, essential diagrams, and safety tips you need.

Table of Contents

ToggleI. Why Anti-Siphon Protection is Essential

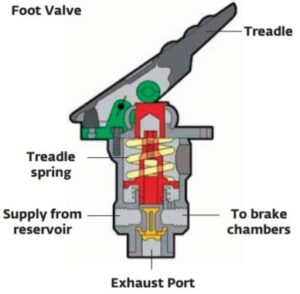

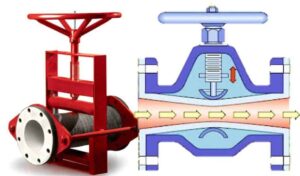

An anti-siphon valve (or Vacuum Breaker) is a simple form of backflow prevention. When water pressure suddenly drops in the main line (due to a break or a fire hydrant use), this can create a vacuum. If your hose is submerged in a chemical pool, a bucket of fertilizer, or dirty water, the vacuum can siphon (suck) that contaminated water backward into your clean, potable water supply.

The anti-siphon valve prevents this by automatically venting air into the line when the pressure drops, breaking the vacuum and stopping the backflow.

II. Tools and Materials Checklist

To successfully install the anti siphon valve for outdoor faucet, gather the following:

New Anti-Siphon Valve (must match your faucet threading).

Adjustable Wrench or Pliers.

Teflon Tape (or Pipe Thread Sealant).

Rag or Towel.

III. Step-by-Step Anti-Siphon Valve Installation

Follow these steps for quick and safe anti siphon valve installation on a standard threaded outdoor faucet.

Step 1: Shut Off Water Supply

Locate the nearest shut-off valve (usually in the basement or garage) and TURN OFF the water supply to the outdoor faucet you are working on.

Open the outdoor faucet completely to drain any residual water and relieve pressure.

Step 2: Prepare the Faucet Threads

If your faucet already has an old anti-siphon valve or cap, use a wrench to carefully unscrew and remove it.

Clean the faucet threads using a rag to ensure they are free of dirt and debris.

Step 3: Apply Thread Sealant

Wrap the threads of the outdoor faucet with 3-4 layers of Teflon Tape (or apply pipe thread sealant). This ensures a watertight seal and helps prevent the valve from fusing to the faucet over time.

Step 4: Install the Anti-Siphon Valve

Thread the new anti-siphon valve onto the faucet.

HAND-TIGHTEN ONLY initially. Many anti-siphon valves are made of brass or plastic and can be damaged if overtightened.

Use the adjustable wrench or pliers to give it a final snug turn (approximately a quarter to half turn). Do not force it past the point of resistance.

Step 5: Test the System

Slowly turn the water supply back ON to the faucet.

Check for leaks around the new connection. If you see dripping, tighten the valve slightly more.

Turn the faucet on to ensure normal flow. The device is typically silent during normal operation.

IV. Anti-Siphon Valve Diagram: Safety and Compliance

The installation location is crucial for the valve’s function.

Height Requirement: By code, the backflow prevention device (the anti-siphon valve) must be installed at least 6 inches above the highest possible flood level or the highest point where the hose could be submerged. This ensures gravity assists in preventing back-siphonage.

Drainage Holes: Never cover the small holes or vents on the side of the valve. These are the pressure relief points that allow air in and water out when a vacuum occurs. If you notice a small amount of water briefly dripping from these vents when turning the faucet off, this is normal function.

V. Troubleshooting: When the Anti-Siphon Valve Leaks

If your faucet consistently drips or leaks heavily from the small vent holes while running, the valve likely needs simple maintenance:

Problem: The internal rubber seal or float assembly may be dirty or damaged.

Solution: You may need a replacement anti siphon valve or a repair kit. If the valve has a removable cap (often secured by a set screw), you can replace the internal rubber gasket or float.

Permanent Fix: If replacing the internal parts doesn’t work, a full replace anti siphon hose bib procedure might be necessary to ensure safety compliance.