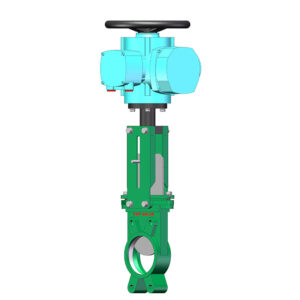

An electric knife gate valve is a widely used automated control valve known for its simple structure, reliable sealing, and large flow capacity.

It is especially suitable for handling slurries, viscous fluids, and solid-containing media in industries such as mining, wastewater treatment, pulp & paper, and chemical processing.

This article provides a detailed overview of the main structural components and functional features of an electric knife gate valve.

Table of Contents

Toggle1. Valve Body

The valve body is the core component of the knife gate valve, forming the main structure that contains the flow passage.

It is usually made of cast iron, ductile iron, carbon steel, or stainless steel through casting or forging processes.

The body houses two opposite sealing surfaces, and the knife gate (disc) moves vertically between them to open or close the flow.

Its compact and flat design allows installation in pipelines with limited space.

2. Sealing Surface

Electric knife gate valves typically use a flat sealing structure.

The knife-shaped gate presses tightly against the valve seat to form a reliable seal, ensuring zero leakage when the valve is fully closed.

Depending on the working conditions, the sealing can be:

Metal-to-metal seal – for high-temperature or abrasive media.

Soft seal (e.g., PTFE or rubber) – for low-pressure or corrosive fluids requiring bubble-tight sealing.

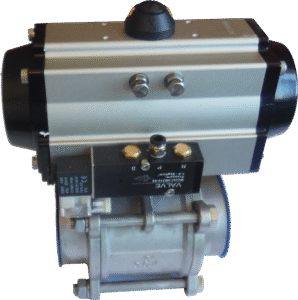

3. Electric Actuator (Drive Mechanism)

The electric actuator serves as the valve’s power source, enabling automatic control without manual operation.

It receives an electrical signal and converts it into linear motion to drive the gate up or down.

A standard actuator assembly includes:

Electric motor – provides driving torque.

Gear mechanism – transmits motion efficiently.

Limit switches & torque limiters – protect the valve from overtravel or overload.

Manual override – allows operation during power failure.

This configuration makes the electric knife gate valve ideal for remote control, automation systems, and high-frequency operations.

4. Knife Gate (Disc)

The knife-shaped gate plate is the primary shut-off element of the valve.

It is a flat, sharp-edged plate usually made from stainless steel or carbon steel, designed to cut through solid particles or fibers within the medium.

When actuated, the gate moves vertically to either:

Open – allowing unrestricted flow through the passage.

Close – pressing against the valve seat to isolate the flow completely.

5. Valve Seat

The valve seat supports the gate and provides the sealing interface.

It is generally made from stainless steel, cast iron, or other corrosion-resistant materials.

The valve seat includes precision-machined sealing faces that tightly contact the gate to prevent leakage.

In some designs, the seat is replaceable or lined with resilient materials like EPDM, NBR, or polyurethane (PU) for better wear and corrosion resistance.

6. Guide Mechanism

To ensure stable and accurate motion of the gate during operation, the valve is equipped with a guide mechanism consisting of guide rods and guide sleeves.

This system prevents lateral movement or vibration, improving the valve’s operational reliability and extending its service life.

7. Sealing Assembly

The sealing system of the electric knife gate valve consists of the seat-to-gate interface and packing seal around the valve stem.

The seat seal ensures tight shut-off, while the packing seal prevents leakage from the stem area.

Common sealing methods include:

Metal-to-metal contact for durability in abrasive conditions.

Elastomer or PTFE packing for chemical resistance and tight sealing.

Summary

An electric knife gate valve is composed of the following main components:

Valve body

Sealing surface

Electric actuator

Knife gate plate

Valve seat

Guide mechanism

Sealing assembly

These parts work together to achieve smooth opening and closing, excellent sealing performance, and long-term reliability even in harsh industrial conditions.

With its automated operation, compact structure, and low maintenance requirements, the electric knife gate valve has become an essential choice for modern industrial fluid control systems.

🔧 Key Advantages at a Glance

Automated operation with precise control

Strong sealing performance under tough conditions

Suitable for slurry, pulp, and wastewater applications

Compact design and easy installation

Long service life with minimal maintenance