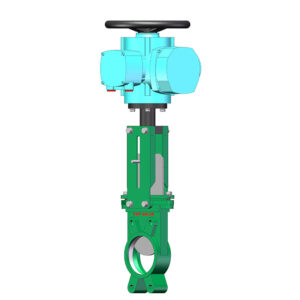

In industrial automation, the performance of a linear valve (such as a globe or gate valve) depends entirely on the “muscles” driving it—the actuator.

When modernizing a plant or designing a new process loop, engineers face a classic dilemma: Should you choose the precision and simplicity of an electric linear actuator, or the rugged, fail-safe reliability of a pneumatic linear actuator? This guide breaks down the technical differences in performance, cost, and environmental suitability.

Table of Contents

Toggle1. The Case for Electric Linear Actuators

An electric linear actuator utilizes a motor (typically stepper or servo) to drive a lead screw or ball screw, converting rotary motion into linear thrust.

Key Advantages:

Superior Precision: Electric linear actuators offer micrometer-level positioning. They are the ideal choice for executing the “Equal Percentage” flow curves discussed in our previous guide.

Infrastructure Savings: They only require electrical cabling. This eliminates the need for expensive air compressors, filters, and complex pneumatic piping—perfect for remote sites or small-scale facilities.

Quiet & Clean: Operating without the “hissing” noise of exhaust air, they are preferred in laboratory, food, and pharmaceutical environments.

The Trade-offs:

Duty Cycle Limits: Continuous high-frequency modulation can lead to heat buildup in the motor.

High Explosion-Proof Costs: In hazardous environments (Class I, Div 1), the specialized enclosures required for electric units are significantly more expensive than pneumatic alternatives.

2. The Case for Pneumatic Linear Actuators

Pneumatic actuators use compressed air to move a piston or diaphragm, creating powerful linear force.

Key Advantages:

High Power Density: For a given size, a pneumatic cylinder can produce much higher thrust than an electric motor, making them ideal for high-pressure linear control valves.

Inherent Safety: Compressed air does not spark, making these the “gold standard” for oil, gas, and chemical refineries.

Reliable Fail-Safe: Integrated spring-return mechanisms allow the valve to automatically move to a safe position (fully open or fully closed) during a power or air loss. This is a critical safety feature for emergency shutdown systems (ESD).

The Trade-offs:

Response Lag: Due to the compressibility of air, pneumatic systems can be less “crisp” in their positioning compared to digital electric drives.

Operational Costs: Running a dedicated instrument air system is energy-intensive and requires constant maintenance to prevent moisture and oil contamination.

3. Technical Comparison Matrix

| Feature | Electric Linear Actuator | Pneumatic Linear Actuator |

| Positioning Accuracy | Excellent (0.01mm) | Moderate (Depends on positioner) |

| Thrust Capability | Moderate | High (Scalable with cylinder size) |

| Fail-Safe Mechanism | Battery/Capacitor Backup | Mechanical Spring (High Reliability) |

| Operating Temperature | -20°C to +60°C (Electronics limited) | -40°C to +120°C (Highly Rugged) |

| Energy Efficiency | High (Energy used only when moving) | Low (Constant loss in air lines) |

4. Selection Criteria: Which One Should You Buy?

When selecting a linear valve actuator, ask your engineering team these three questions:

- Is there an existing instrument air supply?

If yes, pneumatic actuators are generally more cost-effective and rugged. If no, a standalone electric actuator is much cheaper than building an air system from scratch.

- Is high-frequency, precision modulation required?

If your process requires constant, fine-tuned adjustments based on digital sensor feedback, the digital control of a motorized linear actuator is unmatched.

- What is the safety requirement?

For critical safety loops, the mechanical simplicity of a pneumatic spring-return is often preferred over the electronic complexities of a battery-backed electric unit.

5. The Future: Hybrid & Digital Control

The modern trend is moving toward “Smart Actuation.” Even when using pneumatic cylinders, engineers often install digital linear control valve positioners to bridge the gap between pneumatic power and electric precision.

As a specialized linear and rotary valve supplier, we provide both heavy-duty pneumatic solutions and high-resolution linear electric actuators. Our team can help you calculate the required thrust and stroke to ensure your automation system is both safe and efficient.